Method for preparing nanochannels based on proximity ultraviolet exposure and film growth method

A nano-channel and proximity technology, applied in the field of micro-electromechanical research, can solve the problems of difficult nano-channel processing, low production efficiency and high manufacturing cost, and achieve the effects of low price, high production efficiency and easy packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

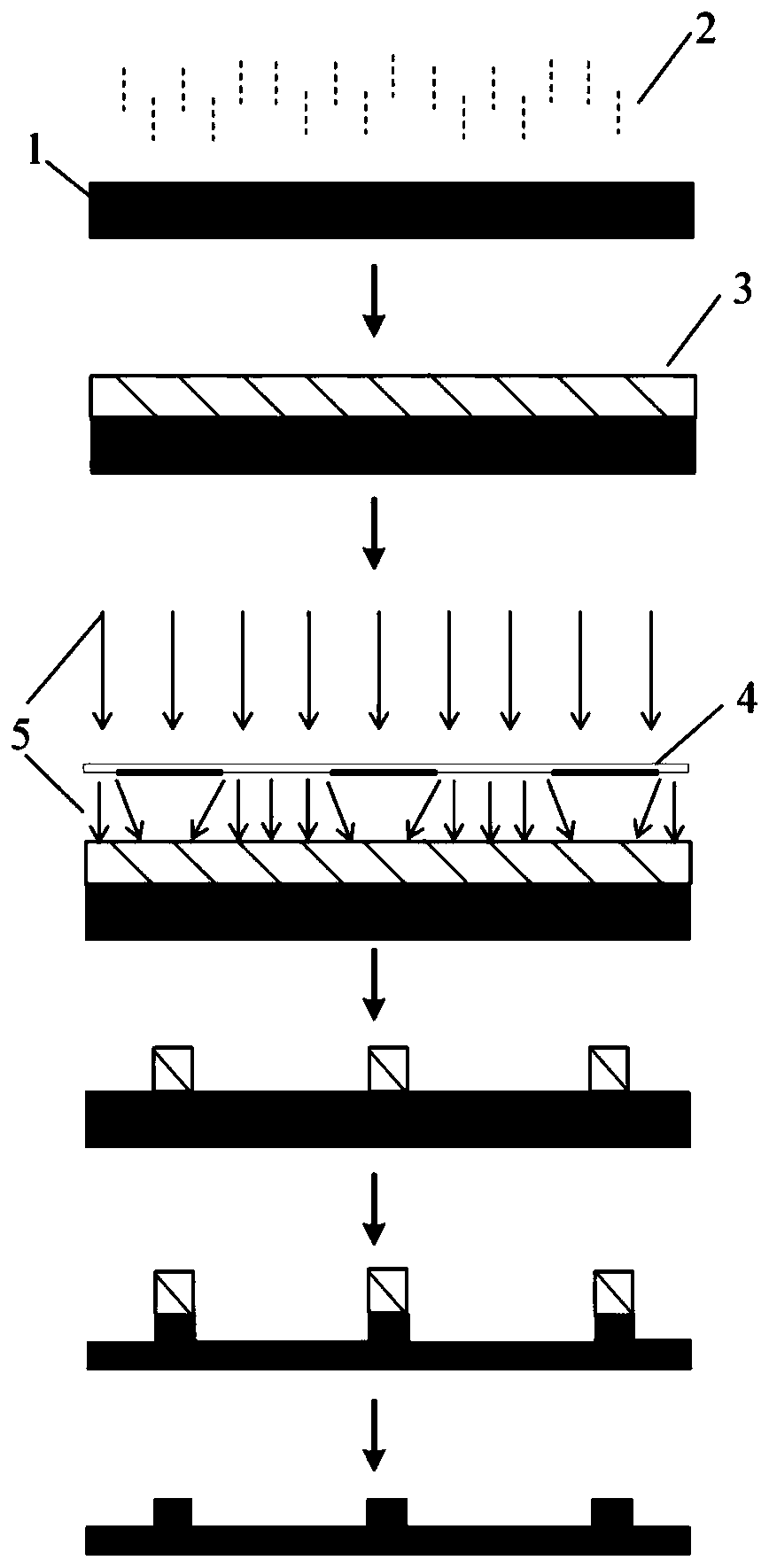

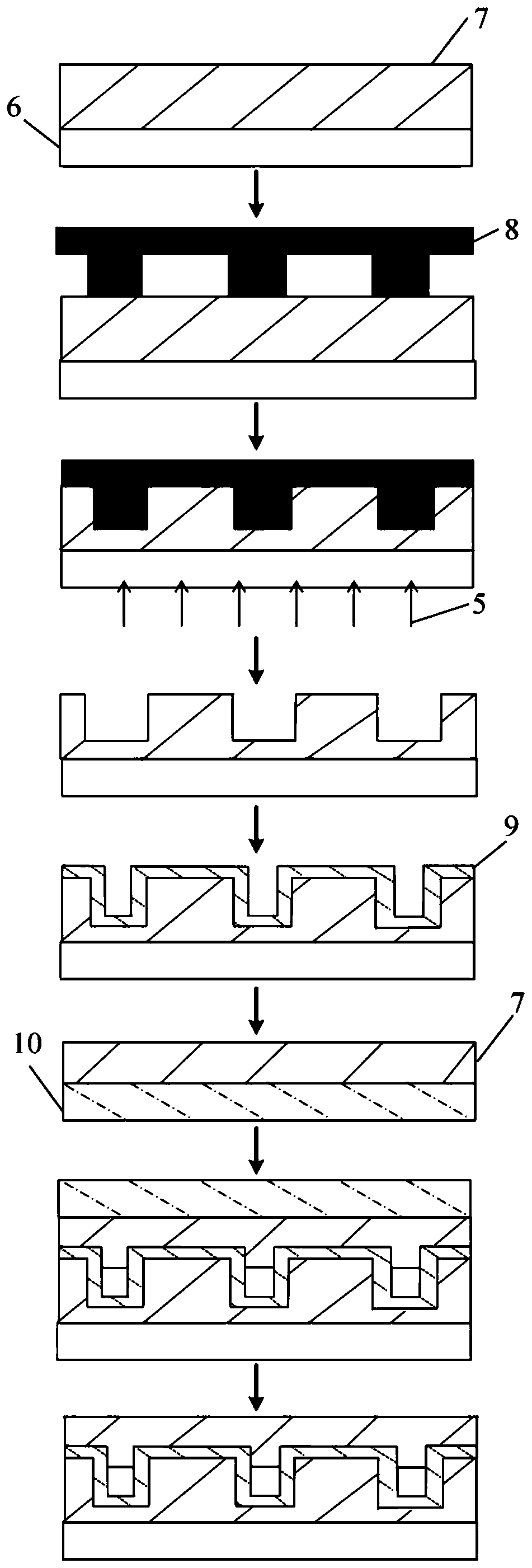

[0030] The specific implementation manner of the present invention will be described in detail below in combination with the technical scheme and accompanying drawings.

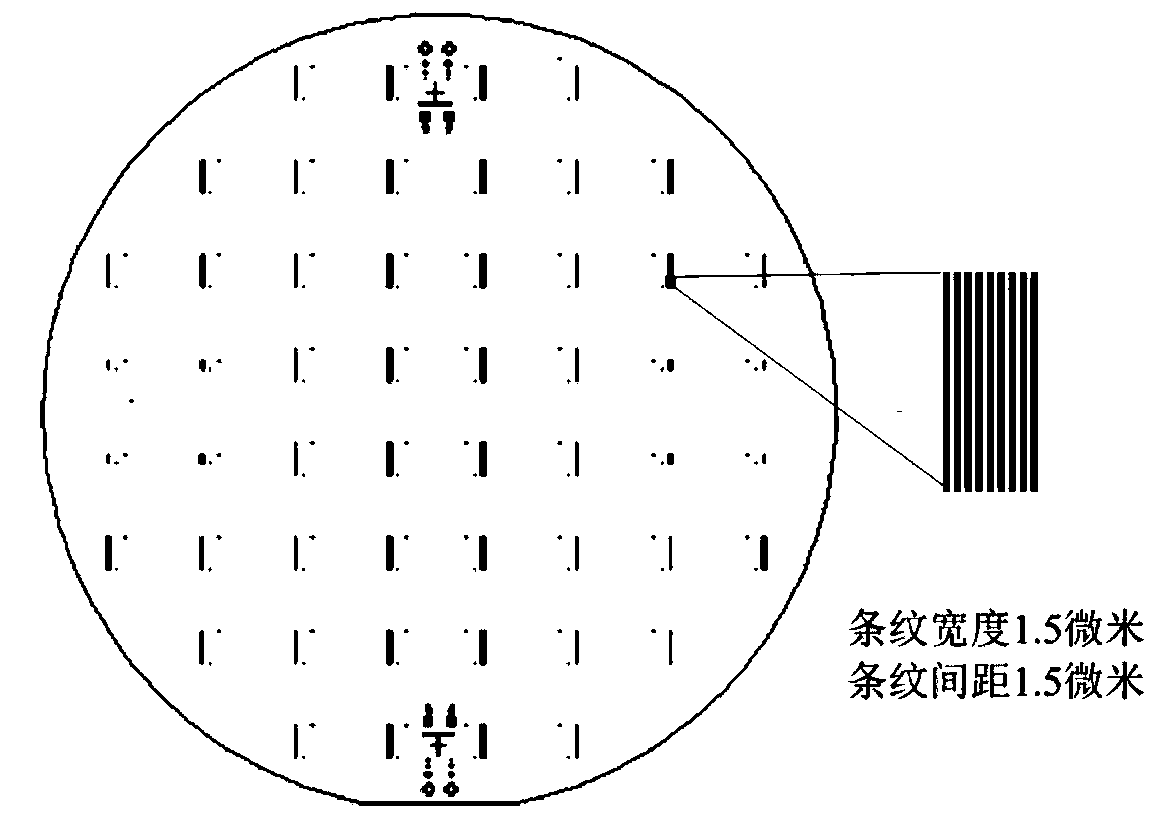

[0031] Such as figure 1As shown, the manufacturing process steps of the silicon nano-mold are as follows:

[0032] (a) Pour a small amount of hexamethyldisiloxane (HMDS) into the drying tower, let it stand for 10 minutes, make the drying tower full of HMDS2 steam, and then place the cleaned 4-inch silicon wafer 1 in the drying tower Treat for 20 minutes, take it out and preheat it on a hot plate for 3 minutes, so that a layer of adhesive layer is formed on the surface of the silicon wafer 1, and the bonding force between the silicon wafer 1 and the AZ703 photoresist 3 is improved.

[0033] (b) Spin-coat positive AZ703 photoresist 3 on the surface-modified silicon wafer 1 at a low speed of 600r / s for 9s, and at a high speed of 7000r / s for 30s. Pre-bake on a hot plate at 85° C. for 30 minutes to remove the so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com