A Method for Improving the Properties of High-Temperature Superconducting Strips Using Electrochemical Method

A technology of high-temperature superconducting strips and chemical methods, applied in the field of improving the performance of high-temperature superconducting strips by electrochemical methods, can solve problems such as the shortage of non-renewable energy sources, improve superconducting transition temperature and critical current density, and improve performance , easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

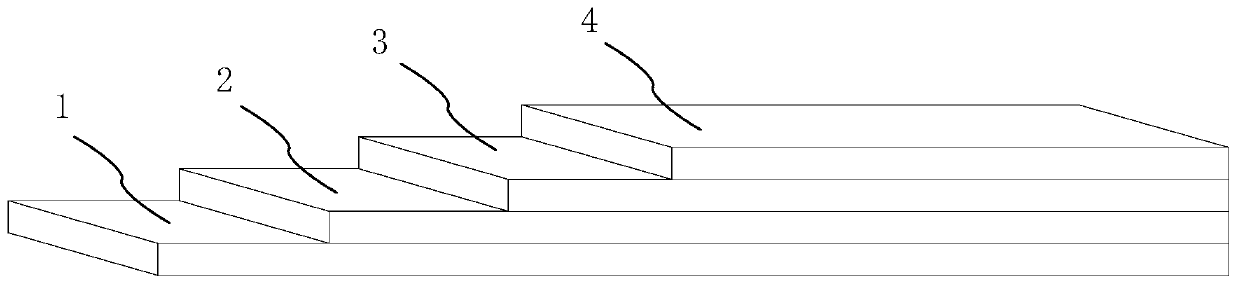

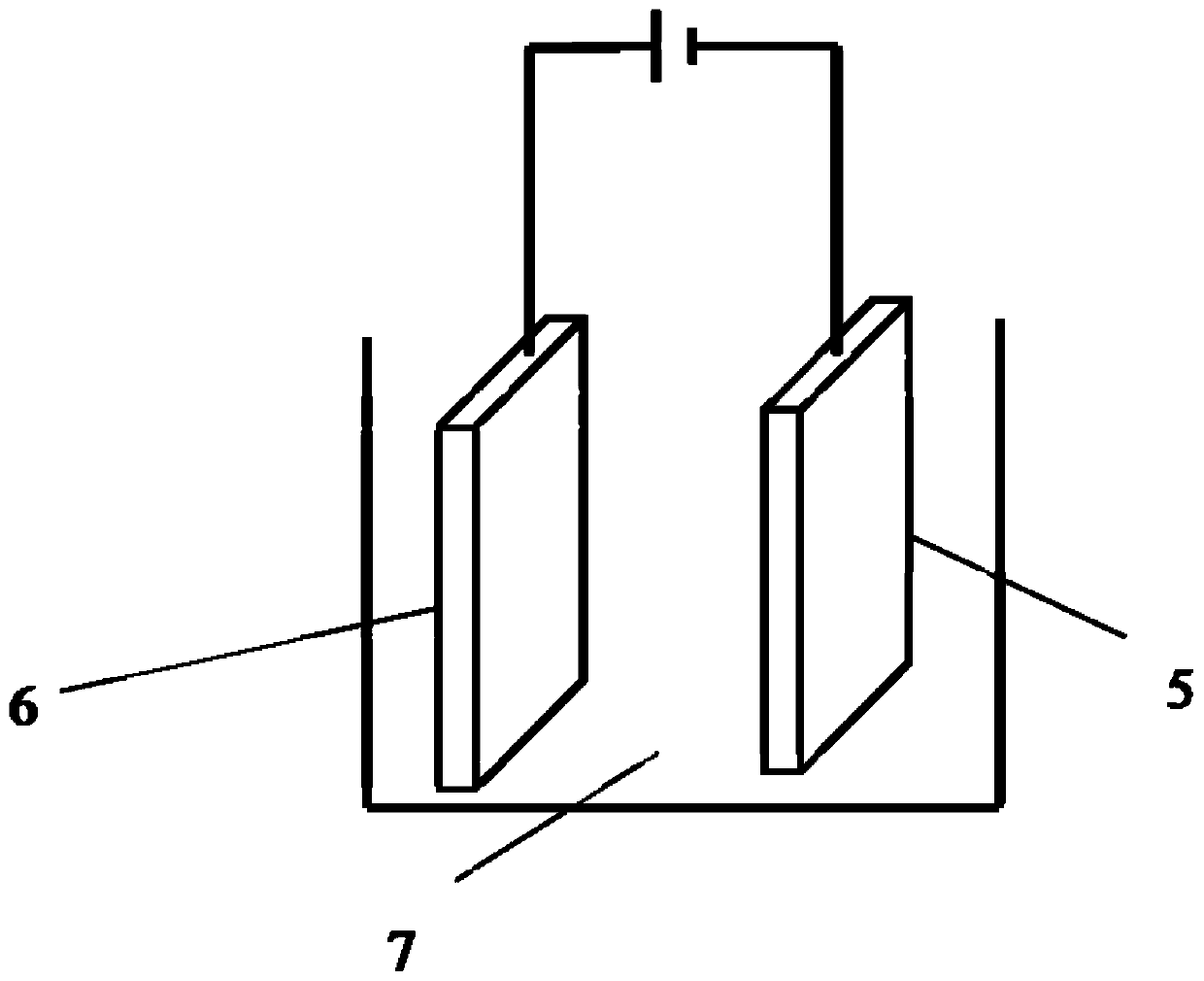

[0034] This embodiment is a method for improving the performance of the YBCO high-temperature superconducting tape by using an electrochemical method, wherein the structural diagram of the high-temperature superconducting tape is as follows figure 1 As shown, it includes a substrate 1, an intermediate layer 2, a REBCO high temperature superconducting layer 3, a protective layer 4, and the like. The intermediate layer 2 includes one or more of alumina, yttrium oxide, magnesium oxide, lanthanum manganate, lanthanum zirconate or cerium oxide. The protective layer 4 includes a silver protective layer. In other embodiments, a copper protection layer may also be deposited on the silver protection layer.

[0035] The method for utilizing the electrochemical method of the present embodiment to improve the performance of the YBCO high-temperature superconducting strip includes the following steps:

[0036] 1. Pour 500ml of acetone into the beaker, seal the mouth of the beaker with ti...

Embodiment 2

[0048] This embodiment is a method for improving the performance of a high-temperature superconducting strip by using an electrochemical method, including the following steps:

[0049] 1. Take 200 ml of organic reagents acetone and methanol, pour them into a beaker and mix thoroughly, seal the mouth of the beaker with tin foil, and put it in a ventilated and dry place for later use.

[0050] 2. Pour 50ml of ammonia water and hydrogen peroxide into another beaker and mix well, seal the mouth of the beaker with tin foil, and put it in a ventilated and dry place for later use.

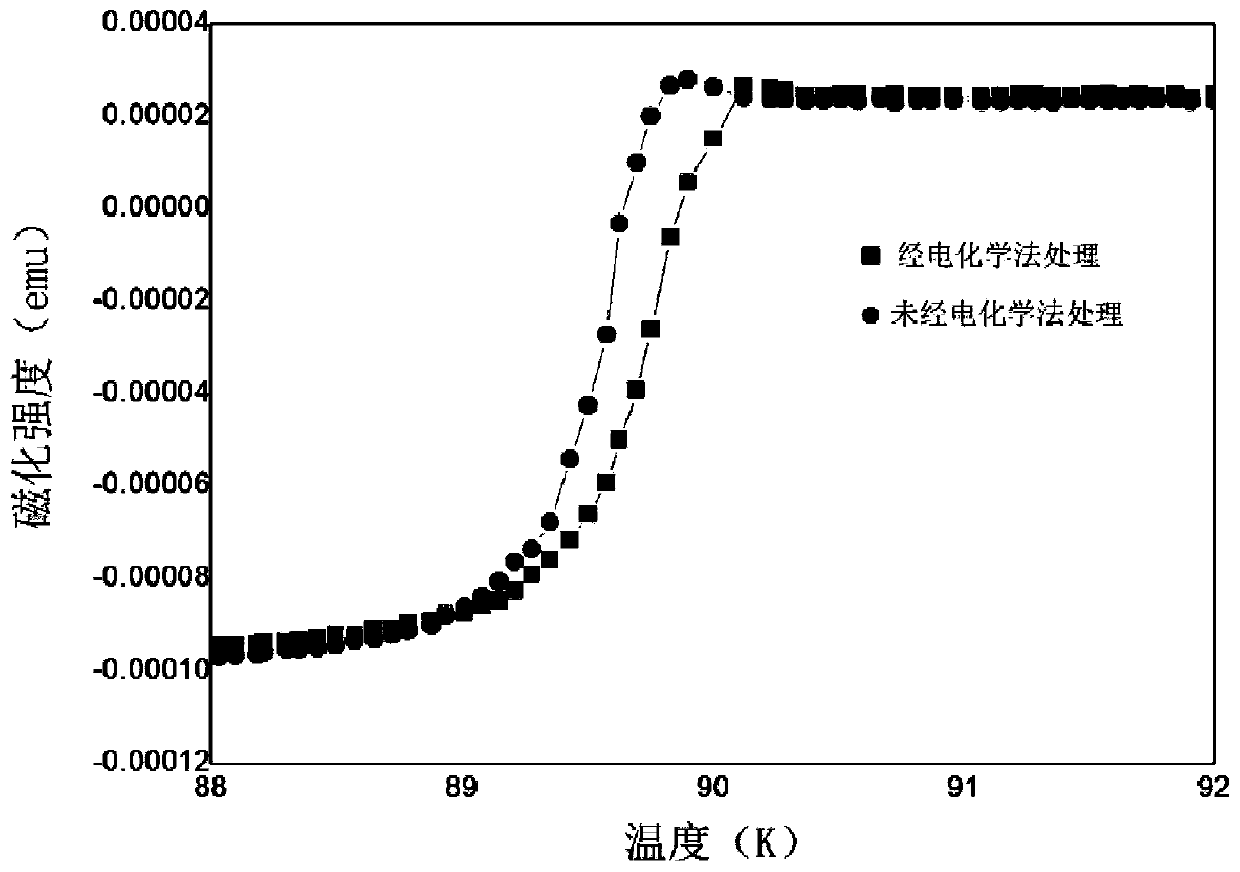

[0051] 3. Take 20 cm of YBCO high-temperature superconducting tape as a sample, and completely immerse the sample in a beaker filled with uniformly mixed ammonia and hydrogen peroxide until the silver on the surface is completely dissolved. Among them, the YBCO high-temperature superconducting tape is deposited on the NiW base tape by the pulsed laser deposition method, and the cerium oxide intermediate lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com