Preparation method of natural flavor for cigarettes

A tobacco flavor and natural technology, applied in the direction of essential oil/flavor, fat production, etc., can solve the problems of cigarette aroma and aroma loss, loss of original style of taste, taste, and decrease of physiological strength of taste, etc., to achieve odor improvement , enrich the hydroxyl and epoxy groups, enhance the effect of hydrogen bond force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

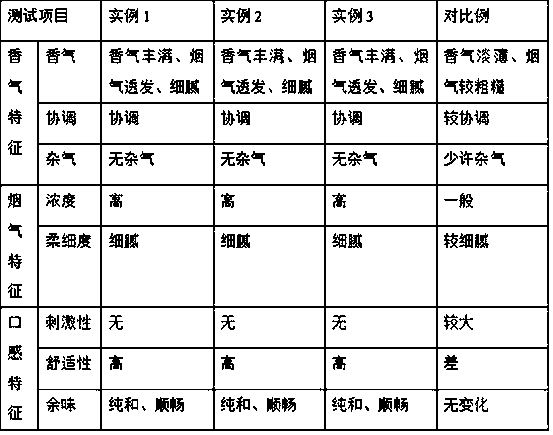

Examples

example 1

[0024]Mix 20g of moso bamboo leaves, 40mg of graphene oxide, and 200mL of ethanol solution with a mass fraction of 60% and place them in a beater for 20 minutes to obtain bamboo leaf pulp. Put the bamboo leaf pulp in a reflux device and heat up to 70°C , heat-preserved and refluxed for 1.0h to obtain a crude extract, which was placed in a rotary evaporator and concentrated at 70°C for 10 minutes to obtain a flavonoid extract; Sugar solution and 2mL acetic acid solution with a mass fraction of 4% were flocculated for 20 hours to obtain a flocculated liquid, and the AB-8 macroporous resin was soaked in absolute ethanol for 20 hours, then packed into a chromatography column for compaction and the air bubbles were discharged. Place absorbent cotton with a thickness of 1mm on the surface of the resin layer, wash the resin layer with absolute ethanol at a flow rate of 10mL / min, put the floc liquid on the resin column, wash with distilled water until the eluent is colorless, and then ...

example 2

[0026] Mix 23g of moso bamboo leaves, 45mg of graphene oxide, and 210mL of ethanol solution with a mass fraction of 60% and place them in a beater for 23 minutes to obtain bamboo leaf pulp. Put the bamboo leaf pulp in a reflux device and heat up to 73°C , heat-preserved and refluxed for 1.3h to obtain a crude extract, which was placed in a rotary evaporator and concentrated at 75°C for 13 minutes to obtain a flavonoid extract; 4.5mL of 5% shell The polysaccharide solution and 2.5mL acetic acid solution with a mass fraction of 4% were flocculated for 22 hours to obtain a flocculated liquid, and the AB-8 macroporous resin was soaked in absolute ethanol for 22 hours, then loaded into a chromatography column and compacted to remove air bubbles , place absorbent cotton with a thickness of 2mm on the surface of the resin layer, wash the resin layer with absolute ethanol at a flow rate of 11mL / min, put the flocculated liquid on the resin column, wash with distilled water until the elu...

example 3

[0028] Mix 25g of moso bamboo leaves, 50mg of graphene oxide, and 220mL of ethanol solution with a mass fraction of 60% and place them in a beater for 25 minutes to obtain bamboo leaf pulp, place the bamboo leaf pulp in a reflux device, and heat up to 75°C , heat preservation and reflux for 1.5h to obtain the crude extract, put the crude extract in a rotary evaporator, and concentrate at 80°C for 15min to obtain a flavonoid extract; add 5mL chitosan with a mass fraction of 5% to 30mL Sugar solution and 3mL acetic acid solution with a mass fraction of 4% were flocculated for 24 hours to obtain a flocculated liquid, and the AB-8 macroporous resin was soaked in absolute ethanol for 24 hours, then packed into a chromatographic column for compaction, and the air bubbles were discharged. Place absorbent cotton with a thickness of 3mm on the surface of the resin layer, wash the resin layer with absolute ethanol at a flow rate of 12mL / min, put the floc liquid on the resin column, wash ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com