Graphene-coated porous red phosphorus, conductive carbon composite material, preparation method and application

A technology of graphene coating and composite materials, which is applied in the direction of circuits, electrical components, battery electrodes, etc., can solve the problems of poor electrical conductivity, low electronic conductivity, and low phosphorus loading, so as to improve electrochemical performance, The treatment process is simple and the effect of alleviating volume expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The present embodiment provides a kind of preparation method of graphene-coated porous red phosphorus, carbon black composite material, comprises the following steps:

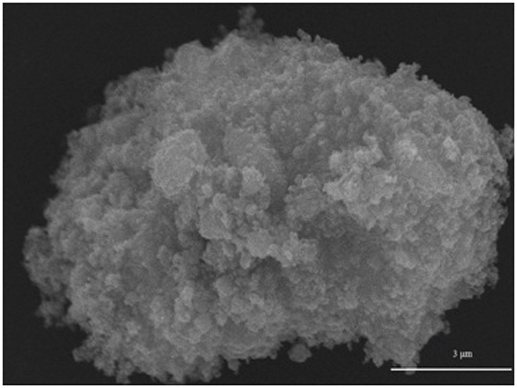

[0031] 1. Preparation of red phosphorus and carbon black composite material: take red phosphorus and carbon black by weighing 8:1 in the ball mill tank of the ball mill, fill the ball mill tank with high-purity argon, and carry out ball milling. The rotating speed of the ball mill is set to 600 r / min for 20 h to obtain red phosphorus and carbon black composite materials, such as figure 1 shown.

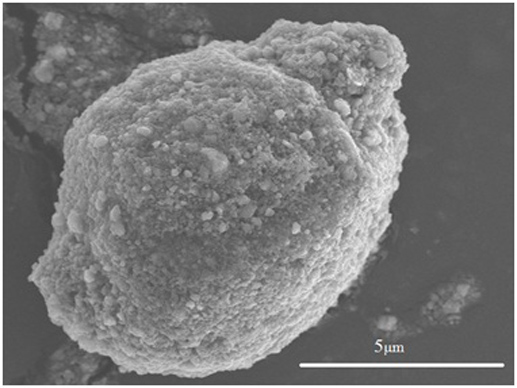

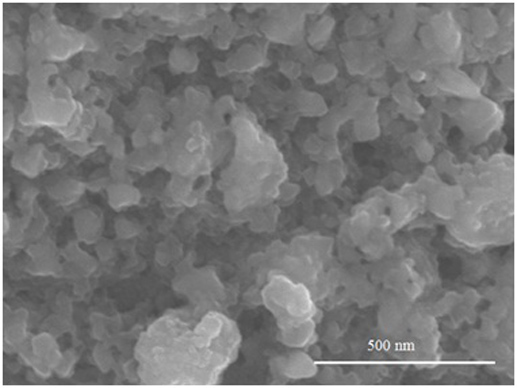

[0032] 2. Preparation of porous red phosphorus and carbon black composite materials: red phosphorus and carbon black composite materials were oxidized in a blast oven, the oxidation temperature was set at 120 °C, and the time was 0.5 h, and then deionized water was added dropwise Suction filtration, washing, and finally drying in a vacuum oven at 80 °C, the porous red phosphorus and carbon black composite mat...

Embodiment 2

[0035] The present embodiment provides a kind of preparation method of graphene-coated porous red phosphorus, carbon black composite material, comprises the following steps:

[0036] 1. Preparation of red phosphorus and carbon black composite material: take red phosphorus and carbon black by weighing 5:1 in the ball mill jar of the ball mill, fill the ball mill jar with high-purity argon, and carry out ball milling. The rotating speed of the ball mill is set to 800 r / min for 3 h to obtain red phosphorus and carbon black composite materials.

[0037] 2. Preparation of porous red phosphorus and carbon black composite materials: red phosphorus and carbon black composite materials were oxidized in a blast oven, the oxidation temperature was set at 150 °C, the time was 1 h, and then deionized water was added and centrifuged. Wash, and finally dry in a vacuum oven at 90 °C to form a porous red phosphorus and carbon black composite material.

[0038] 3. Preparation of graphene-co...

Embodiment 3

[0040] The present embodiment provides a kind of preparation method of graphene-coated porous red phosphorus, carbon black composite material, comprises the following steps:

[0041] 1. Preparation of red phosphorus and carbon black composite material: take red phosphorus and carbon black by weighing 1:1 in the ball mill tank of the ball mill, fill high-purity nitrogen in the ball mill tank, and carry out ball milling. The rotating speed of the ball mill is set to 500 r / min for 64 h to obtain red phosphorus and carbon black composite materials.

[0042] 2. Preparation of porous red phosphorus and carbon black composite materials: red phosphorus and carbon black composite materials were oxidized in a blast oven, the oxidation temperature was set at 60 °C for 4 h, and then deionized water was added dropwise Suction filtration, washing, and finally drying in a vacuum oven at 120 °C to form a porous red phosphorus and carbon black composite material.

[0043]3. Preparation of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com