Active ingredient of folium ficus caricae capable of inhibiting and killing plant pathogenic fungus as well as production method and application thereof

A technology for plant pathogenic fungi and fig leaves, applied in the field of plant pesticides, can solve problems such as non-target biological damage, environmental pollution, human health hazards, etc., and achieve effects from a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: Fig leaf total extract,

[0025] (1) The dried fig leaves are crushed and passed through a 40-mesh sieve to obtain fig leaf powder.

[0026] (2) Get the 95% ethanol that is equivalent to about 7 times of the raw material quality (the general control range is 5-10 times) volume and extract at room temperature (the temperature is generally in the range of 18-24 ° C) for about 20h (the general control range is 12 -24h).

[0027] (3) Sonicate at about 50°C for 6 hours (the general control range is 4-8 hours). Use a Buchner funnel to filter under negative pressure to remove the residue to obtain the filtrate.

[0028] (4) the residue is further ultrasonically extracted for 6 hours (the general control range is 4-8h) with 95% ethanol equivalent to about 6 times (the general control range is 5-10 times) volume of the raw material quality, so that the activity in the fig leaves The ingredients are fully extracted, filtered with a Buchner funnel under negative p...

Embodiment 2

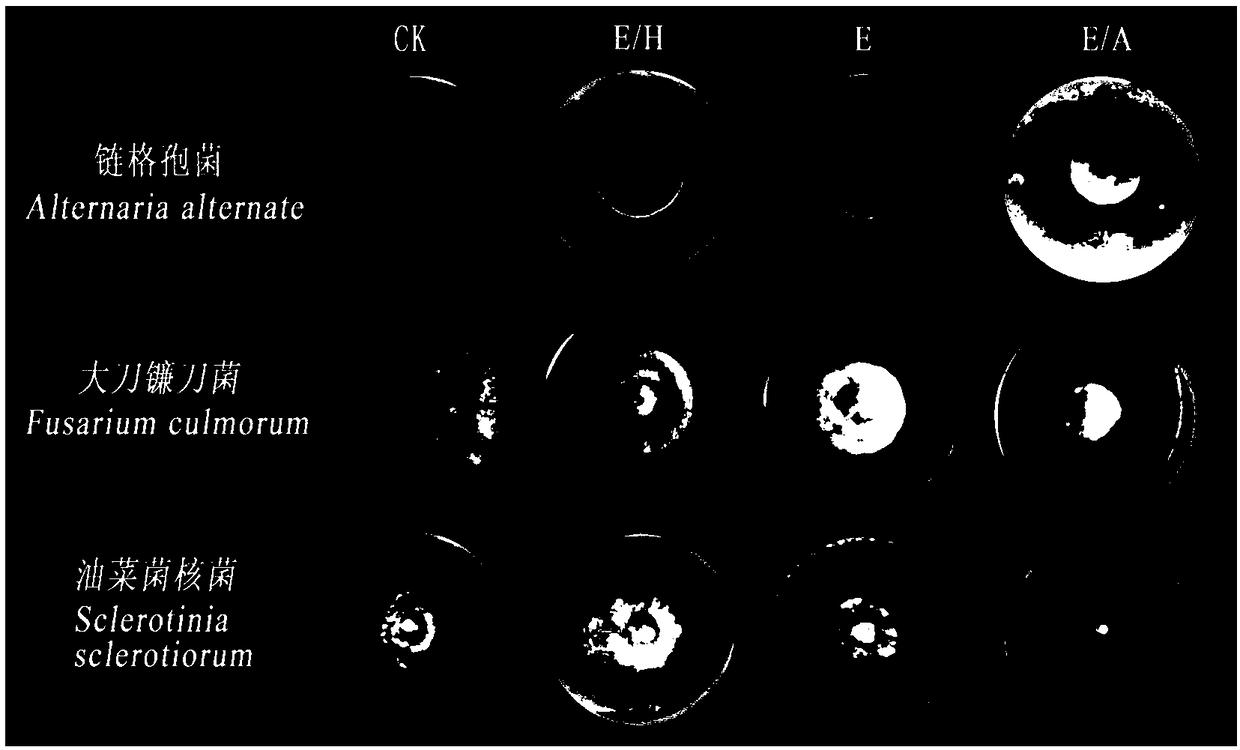

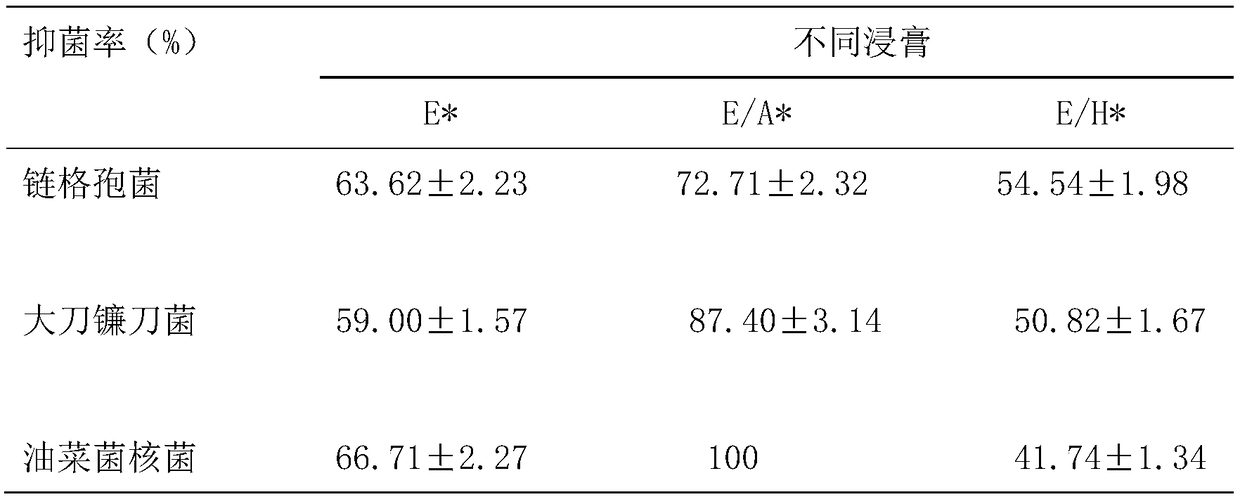

[0031] Embodiment 2: the preparation of n-hexane extract and antibacterial activity assay

[0032] (1) The dried fig leaves are crushed and passed through a 40-mesh sieve to obtain fig leaf powder.

[0033] (2) Get the 95% ethanol that is equivalent to about 7 times of the raw material quality (the general control range is 5-10 times) volume and extract at room temperature (the temperature is generally in the range of 18-24 ° C) for about 20h (the general control range is 12 -24h).

[0034] (3) Sonicate at about 50°C for 6 hours (the general control range is 4-8 hours). Use a Buchner funnel to filter under negative pressure to remove the residue to obtain the filtrate.

[0035](4) the residue is further ultrasonically extracted for 6 hours (the general control range is 4-8h) with 95% ethanol equivalent to about 6 times (the general control range is 5-10 times) volume of the raw material quality, so that the activity in the fig leaves The ingredients are fully extracted, fil...

Embodiment 3

[0039] Embodiment 3 ethyl acetate extract

[0040] (1) The dried fig leaves are crushed and passed through a 40-mesh sieve to obtain fig leaf powder.

[0041] (2) Get the 95% ethanol that is equivalent to about 7 times of the raw material quality (the general control range is 5-10 times) volume and extract at room temperature (the temperature is generally in the range of 18-24 ° C) for about 20h (the general control range is 12 -24h).

[0042] (3) Sonicate at about 50°C for 6 hours (the general control range is 4-8 hours). Use a Buchner funnel to filter under negative pressure to remove the residue to obtain the filtrate.

[0043] (4) the residue is further ultrasonically extracted for 6 hours (the general control range is 4-8h) with 95% ethanol equivalent to about 6 times (the general control range is 5-10 times) volume of the raw material quality, so that the activity in the fig leaves The ingredients are fully extracted, filtered with a Buchner funnel under negative pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com