Preparation method of surface carbon vacancy modified graphite-phase carbon nitride photocatalyst and application of preparation method in production of hydrogen peroxide

A phase carbon nitride light, carbon vacancy technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as low generation efficiency, achieve strong light absorption range, cheap and easy raw materials The effect of easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Step 1. Put 4g of melamine in a 30ml ceramic crucible with a cover, then put the crucible into the center of the muffle furnace, and heat it at 20°C min -1 Raise the temperature to 520°C and keep it warm for 4 hours. After the muffle furnace cools down to room temperature naturally, take out the sample and grind it into a uniform powder with an agate mortar. The sample is ordinary g-C 3 N 4 ;

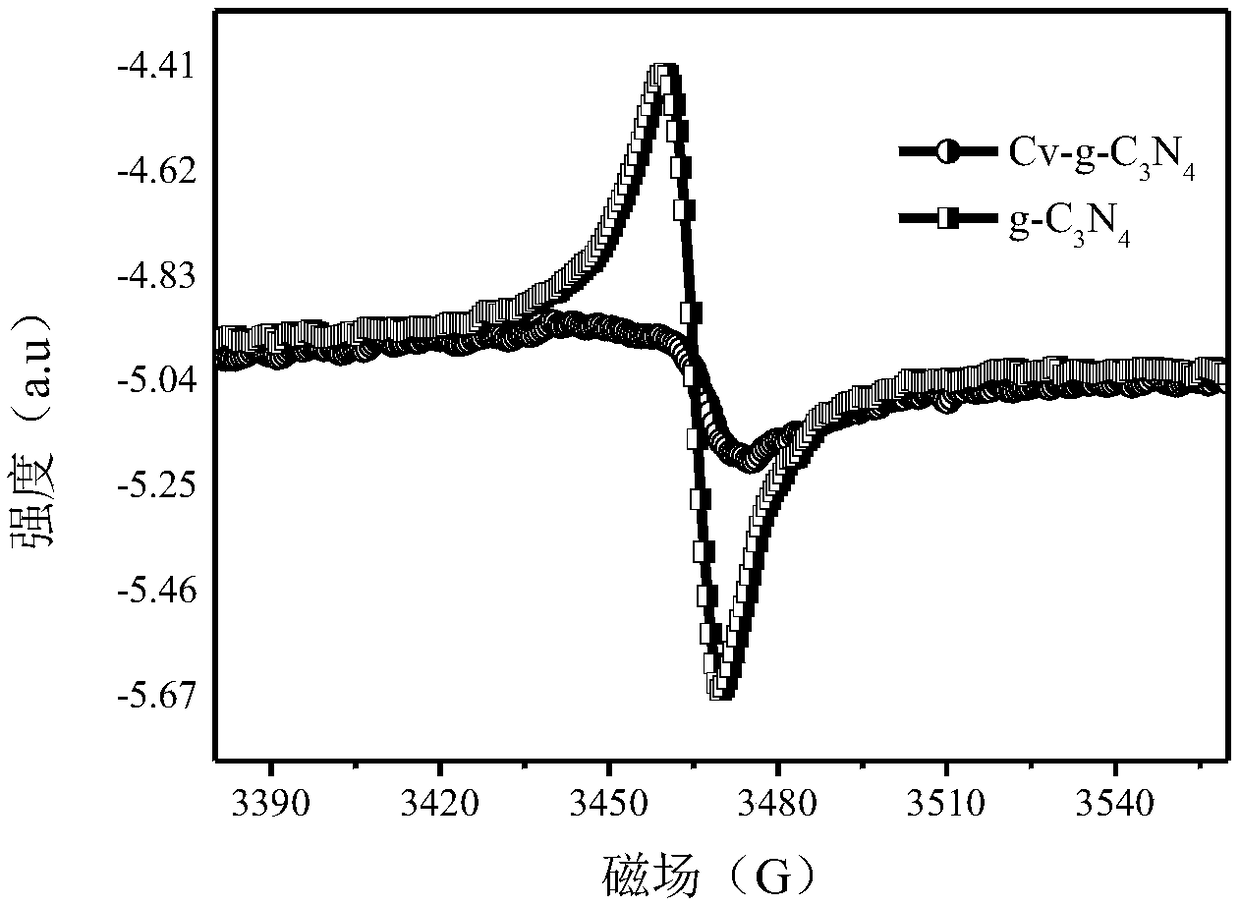

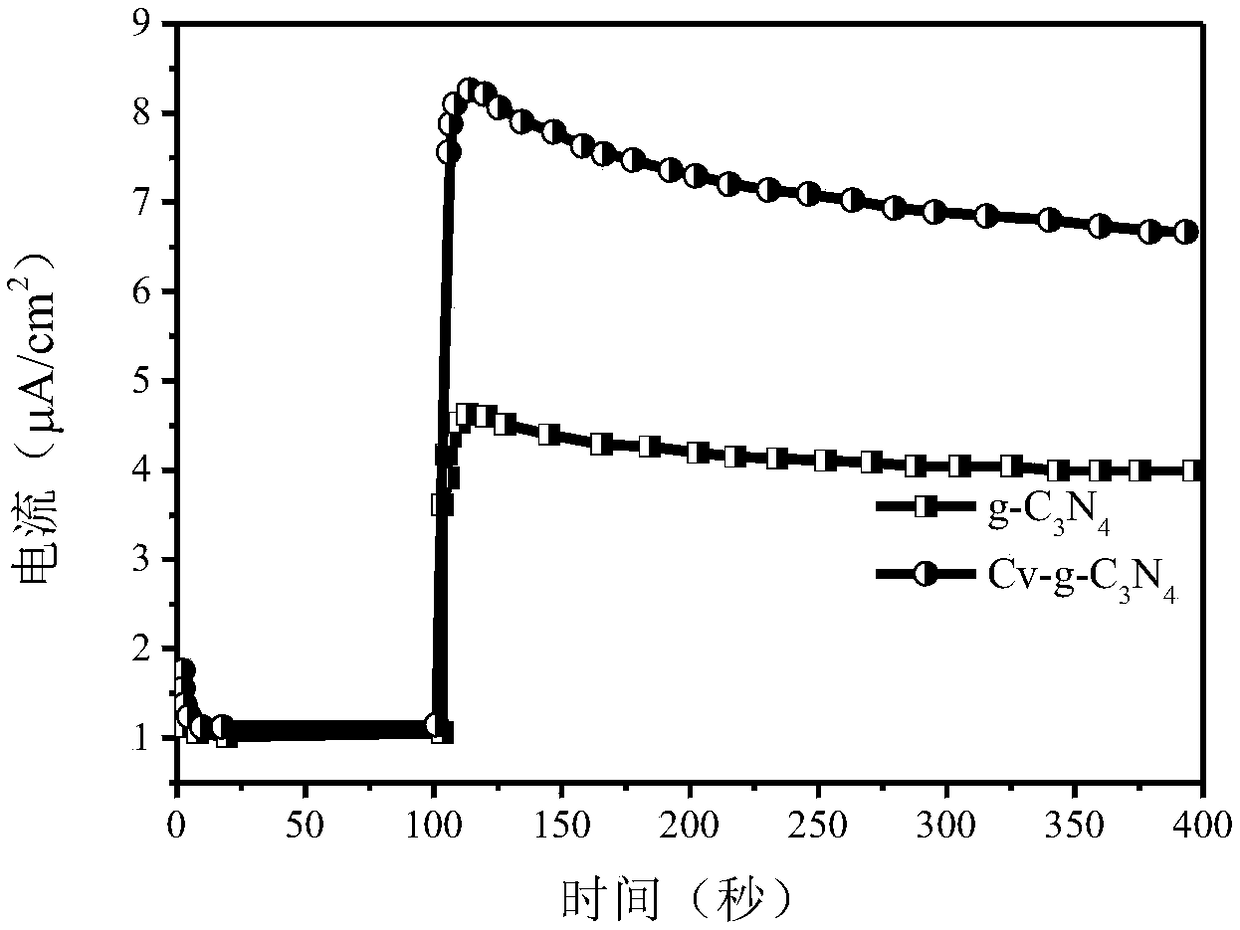

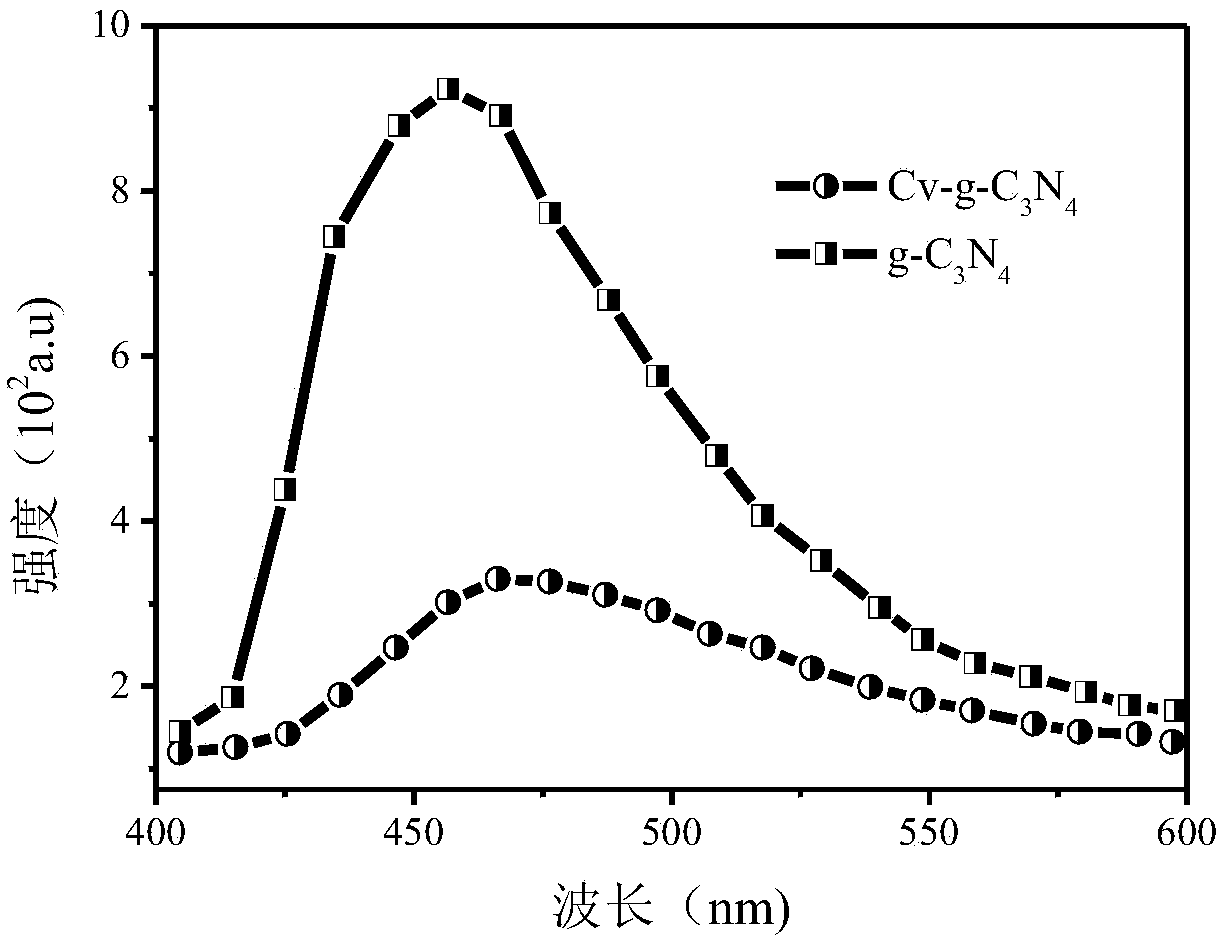

[0025] Step 2, the prepared common g-C 3 N 4 Put it in a 30ml ceramic crucible with a cover, put it into a tube furnace, feed high-purity argon (99.99%) to first expel the air inside, and then heat it in an argon atmosphere at 20°C min -1 The heating rate was raised to 520°C and calcined for 2 hours. After the tube furnace was naturally cooled to room temperature, the sample was taken out and ground into a uniform powder. This sample is g-C modified with surface carbon vacancies 3 N 4 , is named Cv-g-C 3 N 4 ;

[0026] Step 3, Cv-g-C obtained in step 2 respectively 3 N ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com