Preparation method of electrode materials and wastewater treatment method

An electrode material and pretreatment technology, applied in the field of electrochemical catalysis, can solve problems such as high cost and weak cathode oxygen reduction ability, and achieve the effect of increasing process cost, increasing process complexity, and avoiding process complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

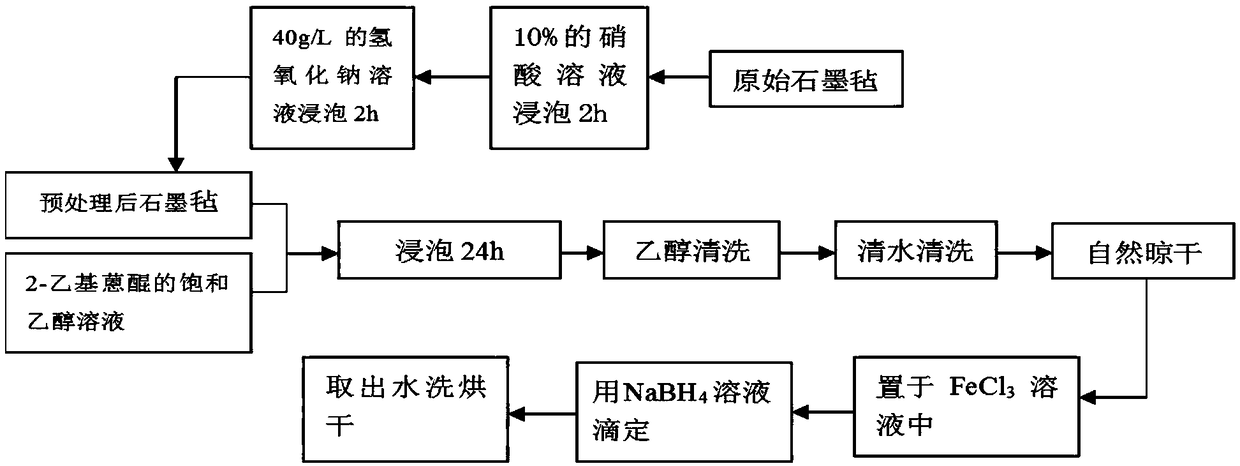

[0028] The invention provides a kind of preparation method of electrode material, and its preparation process is as follows figure 1 Shown:

[0029] 1. Soak the graphite felt in 10% dilute nitric acid solution for 2 hours, take it out, and rinse; then place it in 40g / L sodium hydroxide solution for another 2 hours, take it out, and rinse it to get the pretreated graphite felt. The active components on the surface of the graphite felt can be removed by repeated acid washing and alkali washing.

[0030] 2. Soak the pretreated graphite felt in a saturated ethanol solution of 2-ethylanthraquinone for 24 hours, carry out anthraquinone surface modification, then wash with ethanol and water in sequence, and dry naturally to obtain the first modified graphite felt.

[0031] 3. FeCl 3 ·6H 2 O was dissolved in deionized water to prepare a ferric chloride solution with a concentration of 3 mg / mL for use; NaBH 4 Dissolve in deionized water to prepare NaBH with a concentration of 15mg...

Embodiment 2

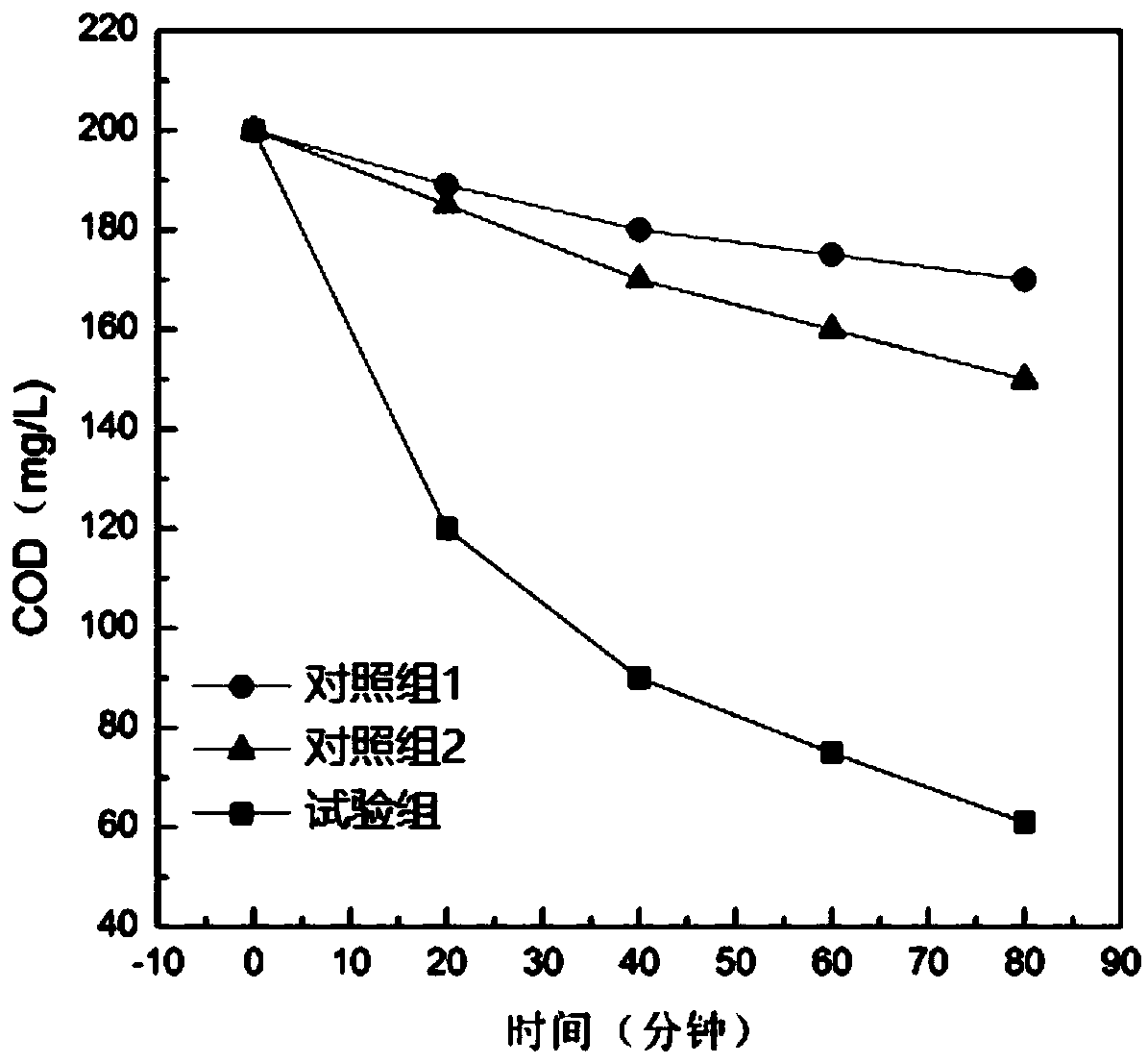

[0034] 1. Grouping

[0035] Get the graphite felt after the pretreatment of embodiment 1 as negative electrode, set as matched group 1;

[0036] Get the first modified graphite felt of embodiment 1 as negative electrode, set as control group 2;

[0037] Get the final product of embodiment 1 as negative electrode, set as test group.

[0038] 2. Wastewater samples

[0039] The wastewater was obtained from a secondary sedimentation tank for livestock and poultry breeding wastewater in Guangdong Province.

[0040] 3. Wastewater electrolysis

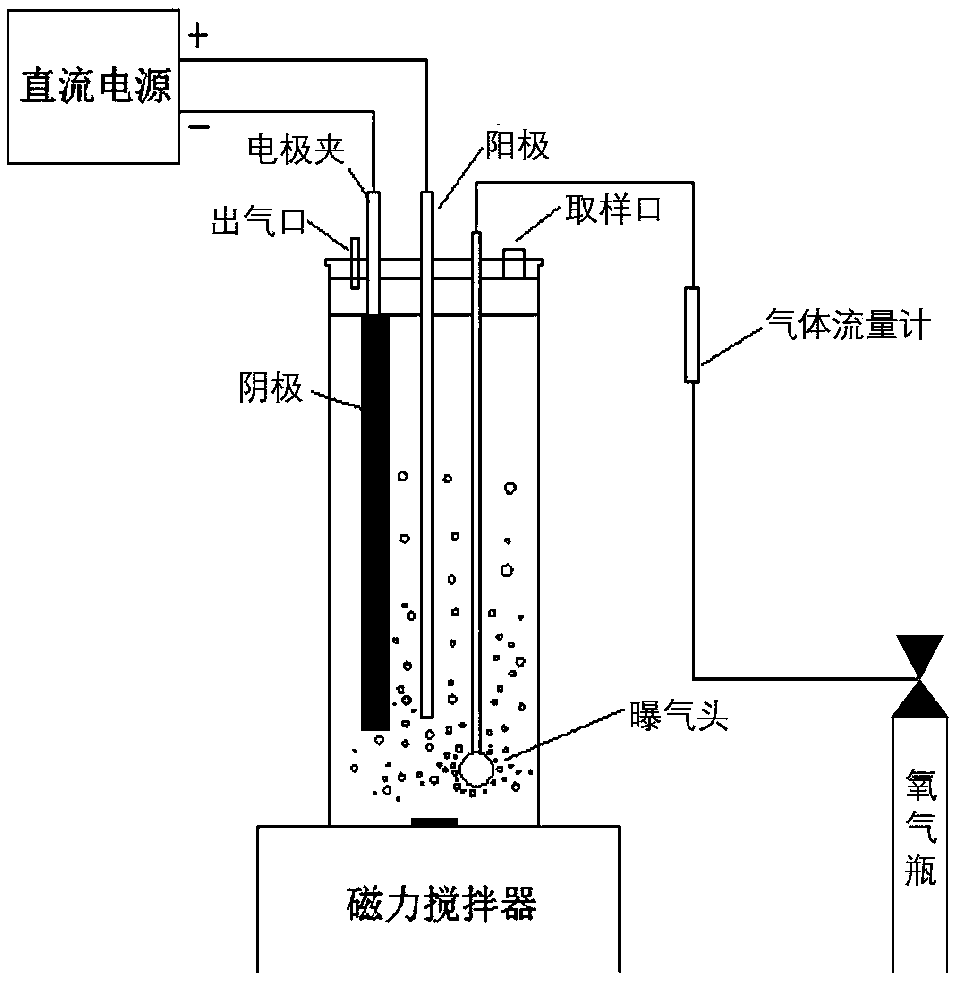

[0041] use as image 3 The electrolysis device shown in the figure performs electrolysis on wastewater, uses carbon rod as anode, saturated calomel electrode as reference electrode, and cathode potential of -0.75V (relative to saturated calomel electrode), and performs electrolysis test on wastewater samples. During the test, the pH was not adjusted (the pH of the solution was measured as neutral before the test), and Fe was not added to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com