Magnetic mesoporous silica nanochain with core-shell structure and preparation method of nanochain

A technology of mesoporous silica and core-shell structure, which is applied in the fields of magnetic materials, magnetic objects, inductors/transformers/magnets, etc., can solve the problem of poor magnetic response effect of composite nanochain materials, difficult control of mesoporous structure, and irregular shape. Uniformity and controllability, etc., to achieve good biocompatibility, simple method, and good magnetic responsiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

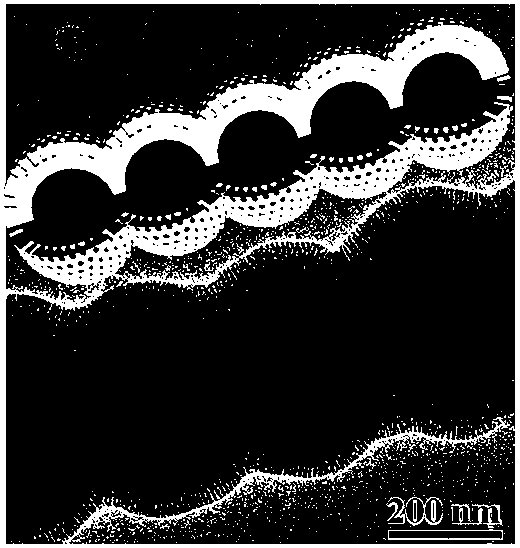

[0025] (1) Disperse 50 mg of magnetic Fe3O4 nanoparticles with a size of 150 nm in a three-necked round-bottomed flask containing 60 mL of absolute ethanol, and disperse them uniformly by ultrasonic dispersion for 10 minutes. 3.0 g of concentrated ammonia solution (28 wt %) was added dropwise to the above mixture, and mechanically stirred at a speed of 700 rpm in a water bath at 30 °C for 20 minutes.

[0026] Reduce the stirring speed to 300 rpm, add 0.3 mL (about 0.28 g) tetraethyl orthosilicate (TEOS) dropwise with a syringe, continue stirring for 15 minutes, stop stirring, and place the solution in a stable magnetic field with a strength of 28.5 mT , for 80 seconds. After the completion, the magnetic field was removed, and the mixture was left to stand for 12 hours, then separated by a magnetic field, and washed with absolute ethanol three times to obtain ferric oxide / silicon dioxide nanochains with a core-shell structure.

[0027](2) Weigh 56 mL of deionized water into a ...

Embodiment 2

[0030] (1) Disperse 50 mg of magnetic Fe3O4 nanoparticles with a size of 250 nm in a three-necked round-bottomed flask containing 60 mL of absolute ethanol, and ultrasonically disperse for 10 minutes to make them uniformly dispersed. 3.0 g of concentrated ammonia solution (28 wt %) was added dropwise to the above mixture, and mechanically stirred at a speed of 700 rpm in a water bath at 30 °C for 20 minutes.

[0031] Reduce the stirring speed to 300 rpm, add 0.4 mL (about 0.37 g) tetraethyl orthosilicate (TEOS) dropwise with a syringe, and continue stirring for 15 minutes, then stop stirring, and place the solution in a stable magnetic field with a strength of 50.5 mT , for 80 seconds. After the completion, the magnetic field was removed, and the mixture was left to stand for 12 hours, then separated by a magnetic field, and washed with absolute ethanol three times to obtain ferric oxide / silicon dioxide nanochains with a core-shell structure.

[0032] (2) Weigh 56 mL of deion...

Embodiment 3

[0035] (1) 80 mg of magnetic NiFe with a size of 300 nm 2 o 4 Nanoparticles were dispersed in a three-necked round-bottom flask containing 60 mL of absolute ethanol, and ultrasonically dispersed for 10 minutes to make them uniformly dispersed. 3.0 g of concentrated ammonia solution (28 wt %) was added dropwise to the above mixture, and mechanically stirred rapidly at a speed of 700 rpm in a water bath at 30 °C for 20 minutes.

[0036] Reduce the stirring speed to 300 rpm, add 0.4 mL (about 0.37 g) tetraethyl orthosilicate (TEOS) dropwise with a syringe, continue stirring for 15 minutes, stop stirring, and place the solution in a stable magnetic field with a strength of 35.5 mT , for 80 seconds. After the end, remove the magnetic field, let the mixture stand for 12 hours, separate it by a magnetic field, and wash it three times with absolute ethanol to obtain NiFe with a core-shell structure. 2 o 4 / Silica nanochains.

[0037] (2) Weigh 56 mL of deionized water into a thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com