Photocatalyst coated carrier material, preparation method thereof and application

A carrier material and photocatalyst technology, applied in the direction of separation methods, chemical instruments and methods, and other chemical processes, can solve the problems of incomplete treatment of harmful substances, achieve both adsorption and decomposition performance, protect the environment, and have remarkable effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

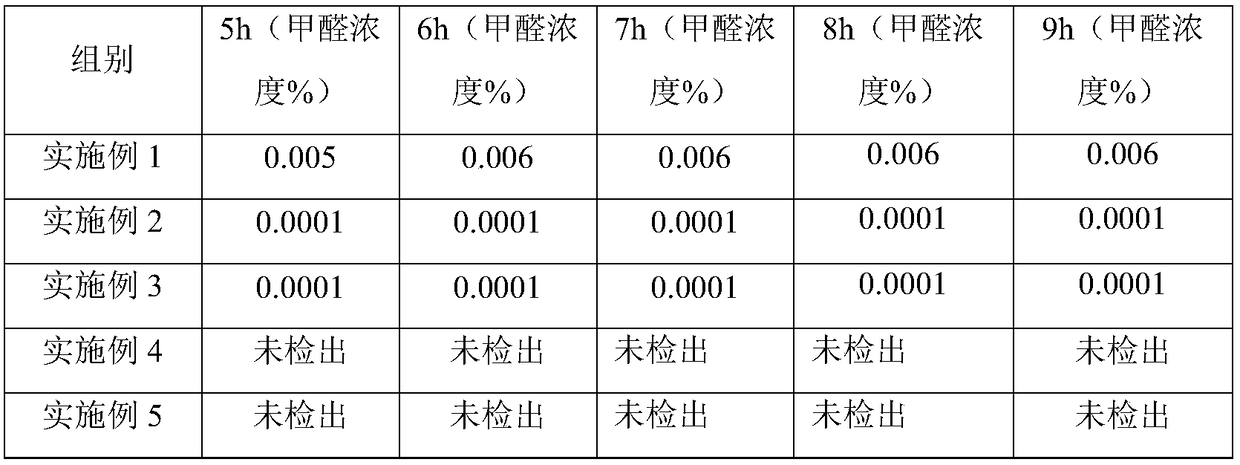

Examples

Embodiment 1

[0032] The preparation method of photocatalyst coated activated carbon material is carried out according to the following steps:

[0033] 1) Soak high-quality activated carbon particles with a particle radius of 2-20nm in a nonpolar ionized water photocatalyst solution (the particle radius of the photocatalyst is 8-10nm) for 24h;

[0034] 2) During the soaking process, the temperature of the solution is controlled between 15-20°C, and the mass percentage concentration of the photocatalyst solution is between 20-30%. After soaking for 24 hours, drain the activated carbon and let it dry naturally for 24 hours for preliminary crystallization. combine;

[0035] 3) Then put it into a drying oven at a constant temperature of 100°C and dry for 8-10 hours for further crystallization, chelation, and solidification.

Embodiment 2

[0037] The preparation method of photocatalyst-coated zeolite material is carried out according to the following steps:

[0038] 1) Soak high-quality zeolite particles with a particle radius of 5-10nm in a nonpolar ionic water nano-titanium dioxide solution (the particle radius of nano-titanium dioxide is 5-6nm) for 26h;

[0039] 2) During the soaking process, the temperature of the solution is controlled between 25-30°C, and the mass percentage concentration of the nano-titanium dioxide solution is between 25-35%. After soaking for 26 hours, the zeolite is drained out, and naturally air-dried for 26 hours for preliminary crystallization chelation;

[0040] 3) Then put it into a drying oven at a constant temperature of 100°C, and dry it for 8-10 hours for further crystallization, chelation, and solidification, and TiO can be seen under a microscope 2 of crystallization.

Embodiment 3

[0042] The preparation method of photocatalyst coated activated carbon material is carried out according to the following steps:

[0043] 1) be the high-quality active carbon grain of 0.35-2nm particle radius, the high-quality activated carbon particle of particle radius 40-50nm, in nonpolar ionic water photocatalyst (nano-titanium dioxide 60wt%, nano-zinc oxide 40wt%) solution (the particle radius of photocatalyst is 9-10nm) for 26 hours;

[0044] 2) During the soaking process, the temperature of the solution is controlled between 20-25°C, and the mass percentage concentration of the photocatalyst solution is between 35-40%. After adding all the substances, mix and stir for 2 hours. After soaking for 26 hours, drain the activated carbon , naturally air-dried for 25 hours, and carried out preliminary crystallization and chelation;

[0045] 3) Then put it into a drying oven at a constant temperature of 100°C and dry for 8-10 hours for further crystallization, chelation, and so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com