PP plastic used for automobile bumper and preparation method thereof

A bumper and automobile technology, applied in the field of plastics, can solve the problems of insufficient mechanical properties, no wear resistance, low heat resistance, etc., and achieve the effects of low hydrophilic-lipophilic balance, improved heat resistance, and high flexural strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

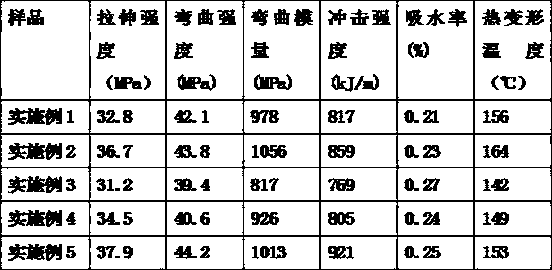

Examples

Embodiment 1

[0024] A kind of PP plastic for automobile bumper, its raw material composition and the ratio of parts by weight are: 100 parts of PP resin, 15 parts of phenolic resin, 20 parts of nitrile rubber, 12 parts of nanometer sodium carbonate, 8 parts of mineral fiber, silicon nitride fiber 4 parts, 1 part of pentaerythritol palmitate lubricant, 0.5 part of 1010 antioxidant, 2 parts of coupling agent, 1.2 parts of stabilizer, 1.5 parts of modifier and 2 parts of processing aid; 1:2 composition of octaphenyl clathrate silsesquioxide and polyoxyethylene stearate.

[0025] The coupling agent is composed of a 2:1 aluminum-zirconium methacrylate coupling agent and a rare earth coupling agent.

[0026] The stabilizer is composed of 2:1 hexamethylcyclotrisilazane and calcium zinc stabilizer.

[0027] The processing aid is composed of oxidized polyethylene wax and nonylphenol polyethylene oxide ether with a mass ratio of 3:1.

[0028] The preparation method of described automobile bumper w...

Embodiment 2

[0033] A kind of PP plastic for automobile bumper, its raw material composition and the ratio of parts by weight are: 100 parts of PP resin, 10 parts of phenolic resin, 25 parts of nitrile rubber, 18 parts of nanometer sodium carbonate, 6 parts of mineral fiber, silicon nitride fiber 5 parts, 1.5 parts of coconut oil diethanolamide lubricants, 1 part of 1076 antioxidants, 1.5 parts of coupling agents, 1 part of stabilizer, 2 parts of modifiers and 1.5 parts of processing aids; It is composed of octaphenyl clathrate silsesquioxide and polyoxyethylene stearate at a ratio of 1:1.

[0034] The coupling agent is composed of a 1:1 aluminum-zirconium methacrylate coupling agent and a rare earth coupling agent.

[0035] The stabilizer is composed of 3:1 hexamethylcyclotrisilazane and calcium zinc stabilizer.

[0036] The processing aid is composed of oxidized polyethylene wax and nonylphenol polyethylene oxide ether with a mass ratio of 2:1.

[0037] The preparation method of descri...

Embodiment 3

[0042] A kind of PP plastics for automobile bumper, its raw material composition and the ratio of parts by weight are: 100 parts of PP resin, 20 parts of phenolic resin, 15 parts of nitrile rubber, 15 parts of nano-sodium carbonate, 10 parts of mineral fiber, silicon nitride fiber 3 parts, 0.5 parts of maleic acid grafted PE wax lubricants, 1.5 parts of CA antioxidants, 2.5 parts of coupling agents, 1.5 parts of stabilizers, 1 part of modifiers and 3 parts of processing aids; It is composed of octaphenyl clathrate silsesquioxane and polyoxyethylene stearate with a mass ratio of 1:2.

[0043] The coupling agent is composed of a 2:1 aluminum-zirconium methacrylate coupling agent and a rare earth coupling agent.

[0044] The stabilizer is composed of 2:1 hexamethylcyclotrisilazane and calcium zinc stabilizer.

[0045] The processing aid is composed of oxidized polyethylene wax and nonylphenol polyethylene oxide ether with a mass ratio of 1:1.

[0046] The preparation method of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com