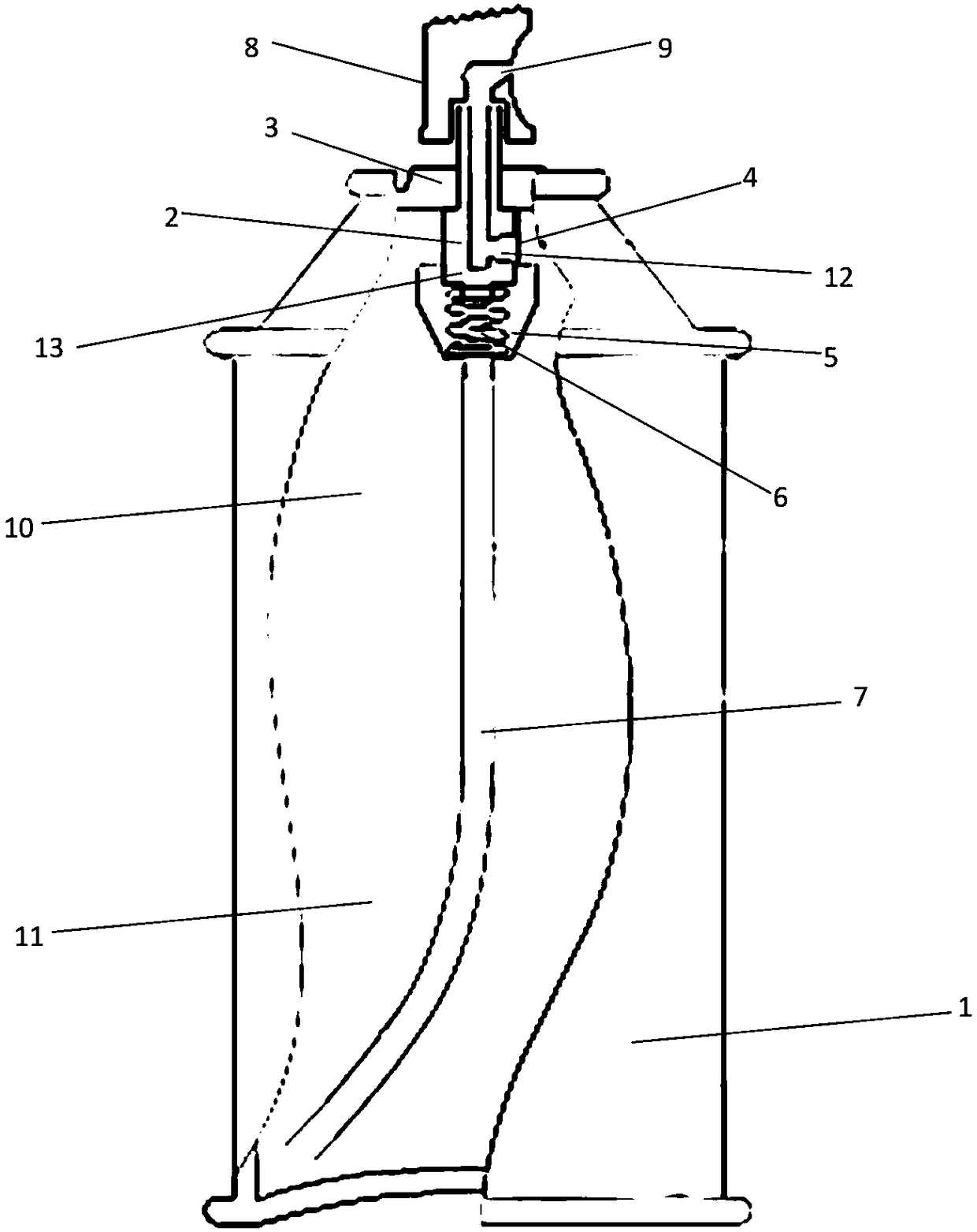

Water-based relief paint and preparation method and automatic spraying device thereof

A relief, water-based technology, applied in the direction of spray device, coating, packaging, etc., can solve the problems of high cost, inconvenient use, limited application of water-based relief paint spraying, etc., to achieve short drying time, simplified structure, good relief effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

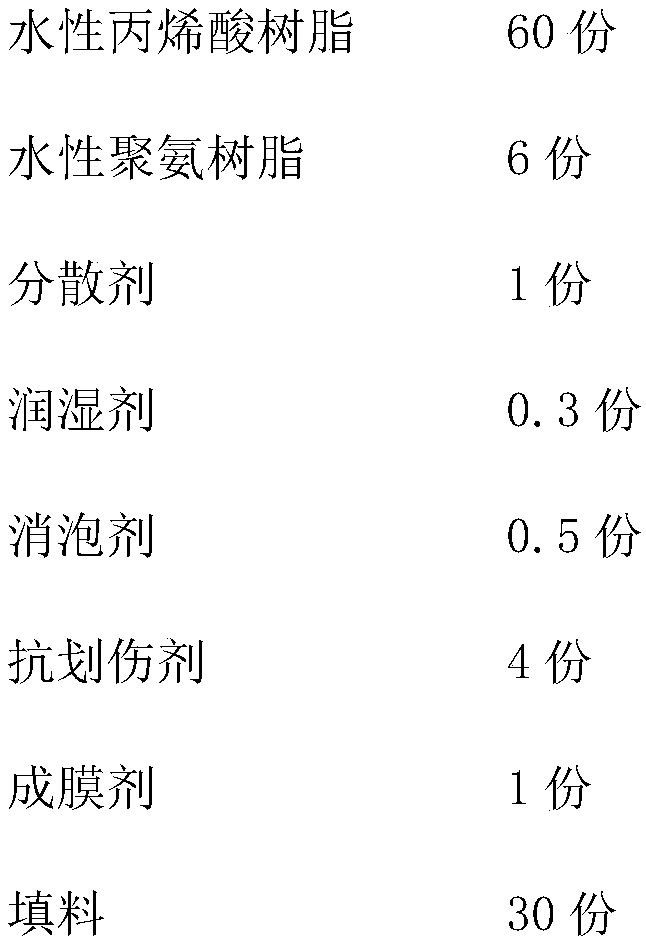

[0048] Embodiment 1 A water-based relief paint, which comprises the following components in parts by weight:

[0049]

[0050]

[0051] The dispersant is maleic acid-acrylic acid copolymer sodium salt; the wetting agent is alkyl benzphenol polyoxyethylene alcohol; the defoamer is polydimethylsiloxane; the anti-scratch agent is polyethylene wax; the thickener is Aluminum silicate; film forming agent is triethylene glycol monoethyl ether; filler is calcium carbonate.

[0052] The preparation method comprises the following steps:

[0053] (1) Add the water-based acrylic resin and the water-based polyurethane resin of the formula dosage into the paint mixing tank, and input the dispersant, wetting agent, defoamer and anti-scratch agent of the formula dosage sequentially while stirring, and the stirring speed is 200r / min, after stirring for 0.5h, homogeneous mixture A was obtained;

[0054] (2) The rotating speed in the paint mixing tank is adjusted to 750r / min, and the fi...

Embodiment 2

[0058] Embodiment 2 A water-based relief paint, which comprises the following components by weight

[0059]

[0060]

[0061] The dispersant is maleic acid-acrylic acid copolymer sodium salt; the wetting agent is alkyl benzphenol polyoxyethylene alcohol; the defoamer is polydimethylsiloxane; the anti-scratch agent is polyethylene wax; the thickener is Hydroxyethyl cellulose; film-forming agent is dipropylene glycol butyl ether; filler is magnesium carbonate.

[0062] (1) Add the water-based acrylic resin and water-based polyurethane resin in the amount of the formula into the paint mixing tank, and put in the dispersant, wetting agent, defoamer and anti-scratch agent in the amount of the formula while stirring, and the stirring speed is 400r / min, after stirring for 0.5h, homogeneous mixture A was obtained;

[0063] (2) Adjust the rotating speed in the paint mixing tank to 1000r / min, add the film-forming agent of formula consumption in the mixture A that step (1) obtain...

Embodiment 3

[0067] Embodiment 3 A water-based relief paint, which comprises the following components by weight

[0068]

[0069]

[0070] The dispersant is maleic acid-acrylic acid copolymer sodium salt; the wetting agent is alkyl benzphenol polyoxyethylene alcohol; the defoamer is polydimethylsiloxane; the anti-scratch agent is polyethylene wax; the thickener is Methyl hydroxypropyl cellulose; film former is propylene glycol; filler is barium sulfate.

[0071] (1) Add the water-based acrylic resin and the water-based polyurethane resin of the formula dosage into the paint mixing tank, and input the dispersant, wetting agent, defoamer and anti-scratch agent of the formula dosage successively while stirring, and the stirring speed is 250r / min, after stirring for 0.5h, homogeneous mixture A was obtained;

[0072] (2) Adjust the rotating speed in the paint mixing tank to 900r / min, add the film-forming agent of formula consumption in the mixture A that step (1) obtains, obtain mixture...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water resistance | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com