Method for producing metallic lead with solvent extraction electrowinning process

A metal lead and electrowinning technology, applied in the direction of improvement of process efficiency, photographic process, photographic auxiliary process, etc., can solve the problems of inapplicability, difficulty in anion separation, etc., and achieve low production cost, strong adaptability of raw materials, and low investment in equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

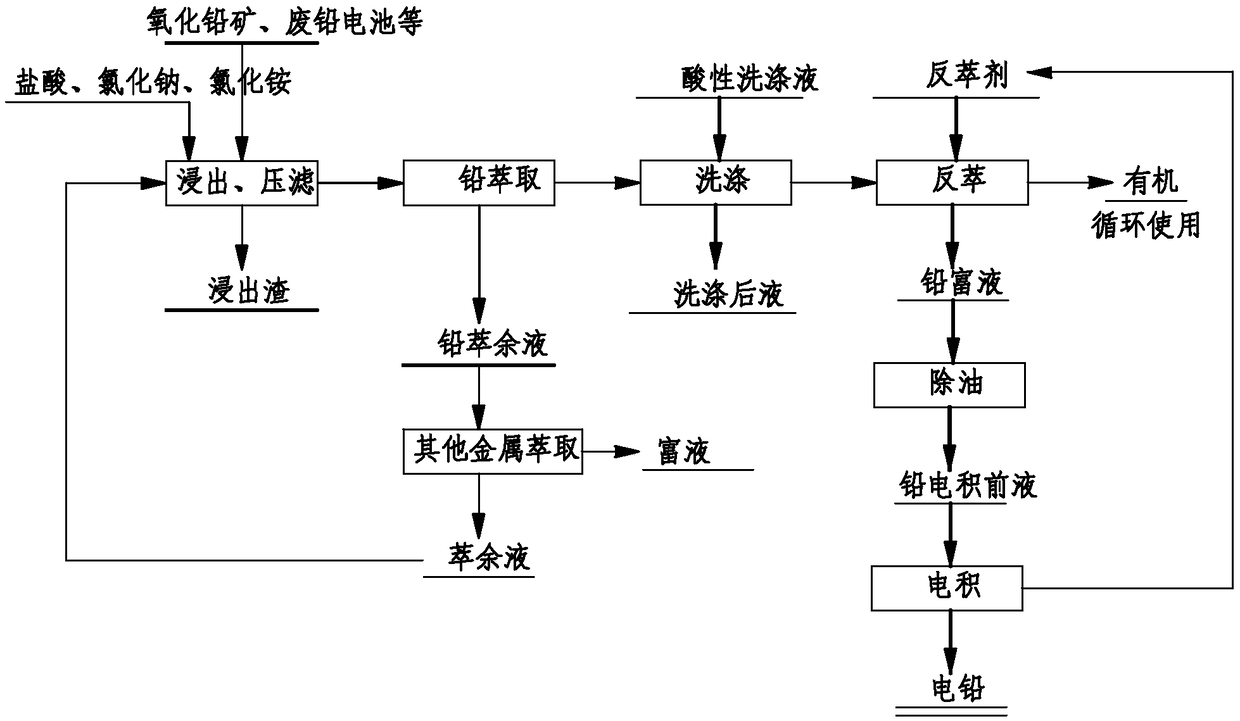

[0039] The lead-containing slag, lead-containing sludge, and lead-zinc materials containing 20% lead are leached and filtered with hydrochloric acid to obtain a lead-containing leachate, which is mixed with the extractant for extraction and shaken for 3 minutes to obtain lead-ion-loaded organic, After the organic matter is washed with an acidic washing solution, it is stripped with a stripping agent to obtain a rich solution containing 150 g / L of lead. The lead-rich solution is degreased by activated carbon to obtain a pre-electrodeposition solution with an oil content of less than 5 ppm. The pre-electrowinning solution obtains metallic lead through electrowinning. After extracting and separating other metals such as copper, cadmium, zinc, cobalt and nickel, the lead extraction raffinate is returned to leaching for recycling. In the above-mentioned embodiment, the acid washing solution is composed of lead acetate and nitric acid, and the stripping agent is composed of nitri...

Embodiment 2

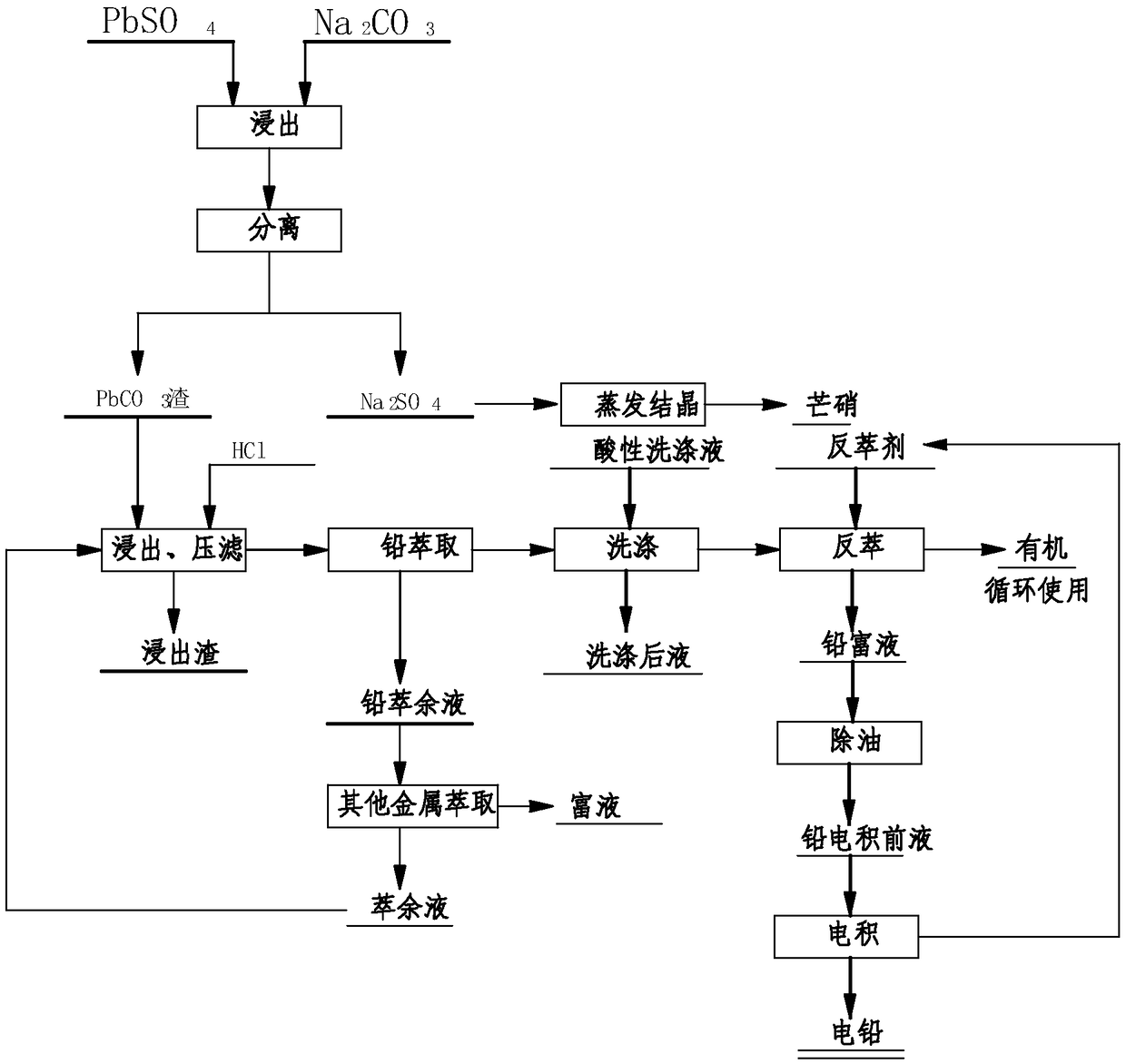

[0041] After leaching and separating the lead sulfate-containing material through a sodium carbonate solution, sodium sulfate solution and lead carbonate precipitation are obtained respectively, the sodium sulfate solution is evaporated and crystallized to prepare Glauber's salt, and the lead carbonate is leached and filtered with hydrochloric acid to obtain a lead-containing leachate; The lead-containing leachate was mixed and extracted with an extractant, and shaken for 5 minutes to obtain an organic substance loaded with lead ions. After the organic substance was washed with an acidic washing solution, it was stripped with a stripping agent to obtain a rich solution containing 150 g / L lead. After the lead-rich solution is degreased by activated carbon, a lead pre-electrowinning solution containing less than 10 ppm of oil is obtained, and the pre-electrowinning solution obtains metallic lead through electrowinning. After extracting and separating other metals such as copper, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com