Preparation method of flexible supercapacitor electrode material applicable to carbon cloth base

A supercapacitor and electrode material technology, applied in the field of electricity, can solve the problems of low specific capacity and weak electrochemical performance of flexible supercapacitors, achieve good chemical stability, improve electrochemical performance, and provide the effect of specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

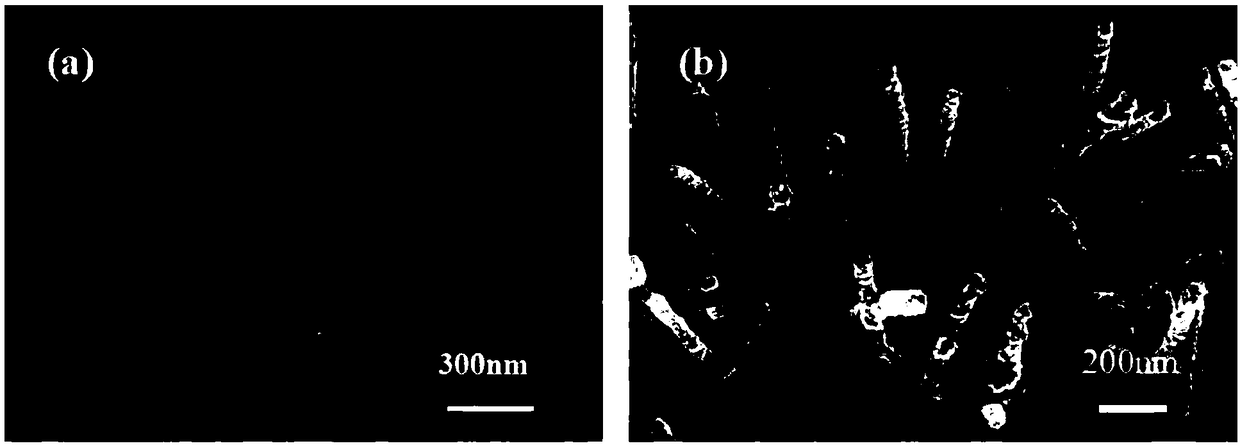

[0025] A flexible supercapacitor electrode material NiCo 2 o 4 @WS 2 method of preparation.

[0026] Cut the commercial carbon cloth into small pieces of 2cm*2cm, and ultrasonically clean them with 1 M sulfuric acid solution, double distilled water and absolute ethanol for ten minutes respectively. Dry and weigh for later use.

[0027] 0.291 g of cobalt nitrate hexahydrate, 0.1454 g of nickel nitrate hexahydrate and 0.2703 g of urea were dissolved in 25 ml of double distilled water, and stirred at room temperature for 30 minutes. Then transfer the pink transparent solution to the reaction kettle, immerse the cleaned carbon cloth on the wall, and react at 120°C for 6 hours.

[0028] The removed carbon cloth was rinsed with double distilled water and absolute ethanol, dried, and weighed. Put it into a tube furnace and anneal at a rate of 2°C / min to 350°C for 2 hours.

[0029] Dissolve 15mg of ammonium tetrathiotungstate in 30ml of DMF, transfer the solution to a reaction k...

Embodiment 2

[0034] A flexible supercapacitor electrode material NiCo 2 o 4 @WS 2 method of preparation.

[0035] Cut the commercial carbon cloth into small pieces of 2cm*2cm, and ultrasonically clean them with 1 M sulfuric acid solution, double distilled water and absolute ethanol for ten minutes respectively. Dry and weigh for later use.

[0036] Dissolve 0.1455 g of cobalt nitrate hexahydrate, 0.0727 g of nickel nitrate hexahydrate and 0.1352 g of urea in 25 ml of double distilled water, and stir for 30 minutes at room temperature. Then transfer the pink transparent solution to the reaction kettle, immerse the cleaned carbon cloth on the wall, and react at 120°C for 6 hours.

[0037] The removed carbon cloth was rinsed with double distilled water and absolute ethanol, dried, and weighed. Put it into a tube furnace and anneal at a rate of 2°C / min to 350°C for 2 hours.

[0038] Dissolve 15mg of ammonium tetrathiotungstate in 30ml of DMF, transfer the solution to a reaction kettle, p...

Embodiment 3

[0042] A flexible supercapacitor electrode material NiCo 2 o 4 @WS 2 method of preparation.

[0043] Cut the commercial carbon cloth into small pieces of 2cm*2cm, and ultrasonically clean them with 1 M sulfuric acid solution, double distilled water and absolute ethanol for ten minutes respectively. Dry and weigh for later use.

[0044] 0.291 g of cobalt nitrate hexahydrate, 0.1454 g of nickel nitrate hexahydrate and 0.2703 g of urea were dissolved in 25 ml of double distilled water, and stirred at room temperature for 30 minutes. Then transfer the pink transparent solution to the reaction kettle, immerse the cleaned carbon cloth on the wall, and react at 120°C for 6 hours.

[0045] The removed carbon cloth was rinsed with double distilled water and absolute ethanol, dried, and weighed. Put it into a tube furnace and anneal at a rate of 2°C / min to 350°C for 2 hours.

[0046] Dissolve 7.5mg of ammonium tetrathiotungstate in 30ml of DMF, transfer the solution to a reaction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com