Ferrocene derivative and preparation method thereof

A technology of ferrocene derivatives and derivatives, applied in chemical instruments and methods, metallocene, organic chemistry, etc., to achieve the effects of high efficiency, short reaction time, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

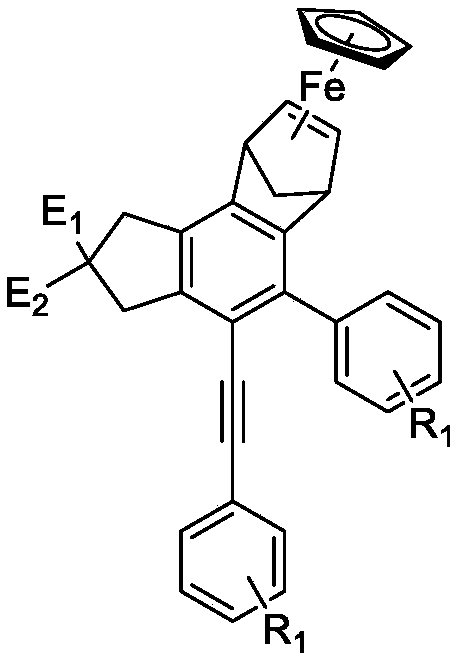

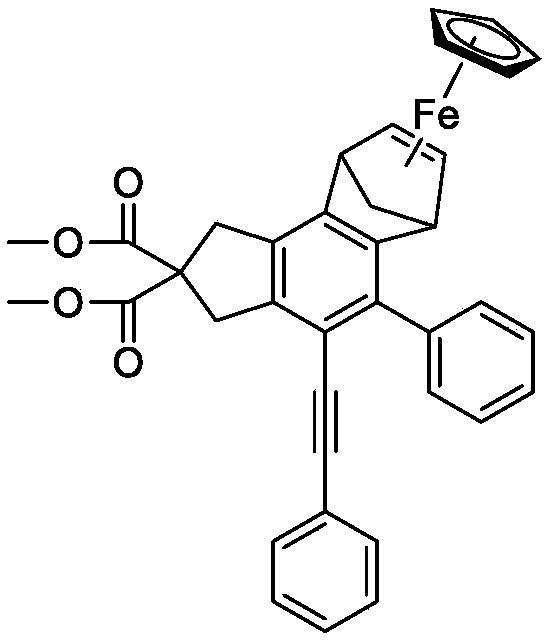

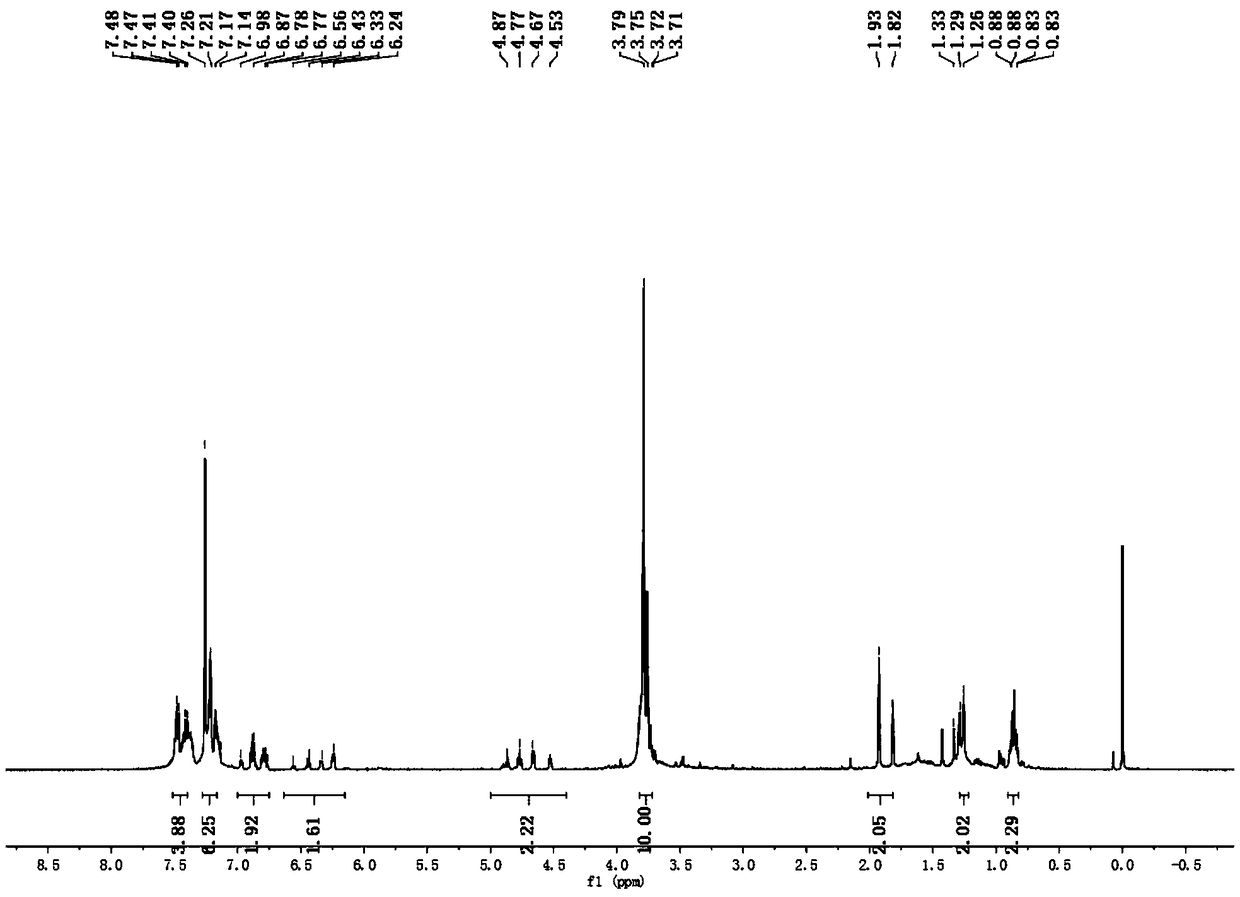

[0047] A ferrocene derivative, the structural formula of the ferrocene derivative is:

[0048]

[0049] The preparation method of above-mentioned ferrocene derivatives, comprises the following steps:

[0050] (1) Using 830mmol of sodium hydride as a catalyst, add 200mmol of dimethyl malonate and 440mmol of propargyl bromide into 210mL of anhydrous acetonitrile in an ice-water bath, stir and react for 8 hours at 0-5°C, and wash the product with water. Extracted with ethyl acetate, and spin-dried under reduced pressure to obtain a brown-yellow solid product, namely compound 1;

[0051]

[0052] (2) Mix 80mmol compound 1 with 200mmol phenylethynyl bromide in Pd(PPh 3 ) 2 Cl 2 / CuI anhydrous and oxygen-free catalytic system (2.56mmol / 0.85mmol), the molar ratio of Pd(PPh 3 ) 2 Cl 2 : CuI=3:1, with 336mmol triethylamine as base, 150mL anhydrous acetonitrile as solvent, stirring and reacting at room temperature for 12 hours, the product was washed with water, extracted wi...

Embodiment 2

[0061] A ferrocene derivative, the structural formula is:

[0062]

[0063] A kind of synthetic method of ferrocene derivative, described synthetic method comprises the following steps:

[0064] (1) With sodium hydride 830mmol as a catalyst, 200mmol dimethyl malonate and 440mmol propargyl bromide were added to 210mL of anhydrous acetonitrile in an ice-water bath, stirred and reacted for 8 hours, the product was washed with water, extracted with ethyl acetate, and Press and spin dry to obtain a brownish-yellow solid product, namely compound 1;

[0065]

[0066] (2) Mix 80mmol of compound 1 with 200mmol of p-methylphenylethynyl bromide in Pd(PPh 3 ) 2 Cl 2 / CuI anhydrous and oxygen-free catalytic system (2.56mmol / 0.85mmol), the molar ratio of Pd(PPh 3 ) 2 Cl 2 : CuI=3:1, with 336mmol triethylamine as base, 150ml anhydrous acetonitrile as solvent, stirred and reacted at room temperature for 12 hours, the product was washed with water, extracted with ethyl acetate, spi...

Embodiment 3

[0076] A ferrocene derivative, the structural formula of the ferrocene derivative is:

[0077]

[0078] A kind of synthetic method of ferrocene derivative, described synthetic method comprises the following steps:

[0079] (1) With sodium hydride 830mmol as a catalyst, 200mmol dimethyl malonate and 440mmol propargyl bromide were added to 210mL of anhydrous acetonitrile in an ice-water bath, stirred and reacted for 8 hours, the product was washed with water, extracted with ethyl acetate, and Press and spin dry to obtain a brownish-yellow solid product, namely compound 1;

[0080]

[0081] (2) Mix 80mmol compound 1 with 200mmol p-ethylphenylethynyl bromide in Pd(PPh 3 ) 2 Cl 2 / CuI anhydrous and oxygen-free catalytic system (2.56mmol / 0.85mmol), the molar ratio of Pd(PPh 3 ) 2 Cl 2 : CuI=3:1, with 336mmol triethylamine as base, 150ml anhydrous acetonitrile as solvent, stirred and reacted at room temperature for 12 hours, the product was washed with water, extracted wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com