Method for preparing metal nano-particle welded silver nano-wire electromagnetic shielding slurry

A metal nanoparticle and silver nanowire technology, applied in the field of nanomaterials, can solve the problems of high contact resistance and poor electromagnetic shielding performance, and achieve the effects of preventing electrical conductivity, reducing contact resistance, and easy adjustment of technical parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

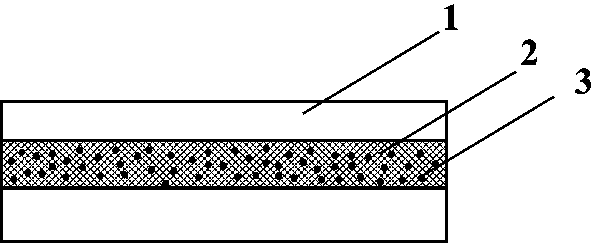

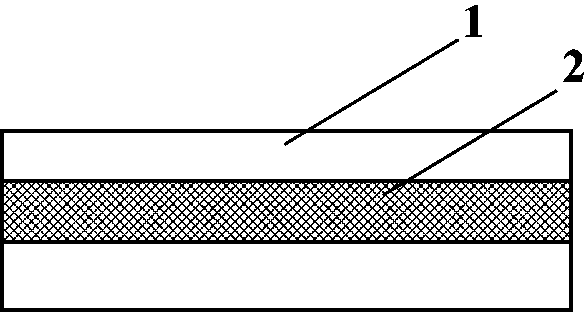

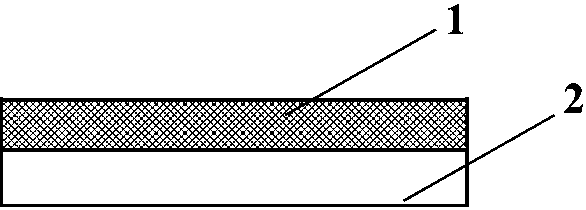

Image

Examples

example 5

[0028] First, a dispersion of silver nanowires is mixed with metal nanoparticles. The silver nanowire solution can be obtained by mixing silver nanowires with a solvent, the diameter of the silver nanowires can be between 20-500 nm, and the aspect ratio is greater than 1000. Theoretically speaking, the smaller the diameter of the silver nanowires and the larger the aspect ratio, the higher the electrical conductivity of the prepared coating, and the greater the electromagnetic shielding effect. In addition, mixing methods include but are not limited to stirring, shaking, low-energy ultrasound, and the like. The solvent may be at least one of deionized water, ethanol, methanol, isopropanol, and DMF. The solid content of the silver nanowire solution may be 1%-30%, preferably 5-15%. The concentration of silver nanowires should not be too high or too low, and serious entanglement and coagulation will not occur, which will affect the uniformity of silver wire distribution during ...

Embodiment 1

[0035] A preparation method of silver nanowire composite metal nanoparticle electromagnetic shielding film:

[0036] Configure silver nanowire solution: mix silver nanowires with a diameter of 50nm (aspect ratio greater than 1000) with ethanol to obtain a silver nanowire solution with a solid content of 8%;

[0037] Add silver nanowires and iron nanoparticles (particle size is about 30 nm) to the solution of silver nanowires at a mass ratio of 1:1, mix and stir thoroughly, and add cysteamine accounting for 1% of the mass of silver nanowires as a soldering agent , kept at 70°C for 30 minutes to obtain soldered silver nanowires, and set aside;

[0038] (1) Mix the polyurethane solution and the soldered silver nanowires at a mass ratio of 1:2, and shake in an air bath constant temperature oscillator at 25°C (180 times / min) for 1 hour;

[0039] (2) Put the mixed polyurethane polymer solution of silver nanowires into a beaker, slowly pump out the air in the cavity with a vacuum pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com