Barrier material, barrier film, preparation method and application thereof

A barrier material and barrier film technology, applied in the field of medical materials, can solve problems such as long operation time, long operation time, and inability to support stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

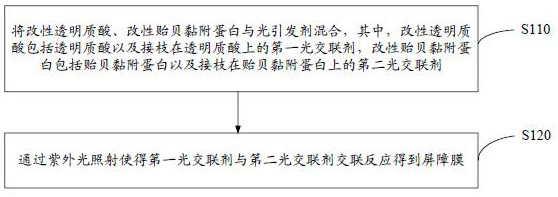

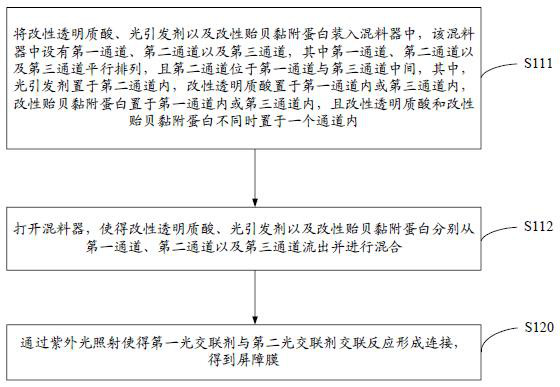

[0042] The flow chart of the preparation method of the barrier film of one embodiment is as follows figure 1 As shown, the barrier film is formed by the above barrier material, including the following steps S110-S120.

[0043] S110. Mix the modified hyaluronic acid, the modified mussel adhesion protein and the photoinitiator, wherein the modified hyaluronic acid includes hyaluronic acid and the first photocrosslinking agent grafted on the hyaluronic acid, and the modified The mussel adhesion protein includes the mussel adhesion protein and the second photocrosslinking agent grafted on the mussel adhesion protein.

[0044] Specifically, the first photocrosslinking agent can be grafted on hyaluronic acid through grafting reaction to obtain modified hyaluronic acid, and the second photocrosslinking agent can be grafted on mussel adhesion protein through grafting reaction to obtain modified hyaluronic acid. Modified mussel adhesion protein. The hyaluronic acid is grafted and mod...

Embodiment 1

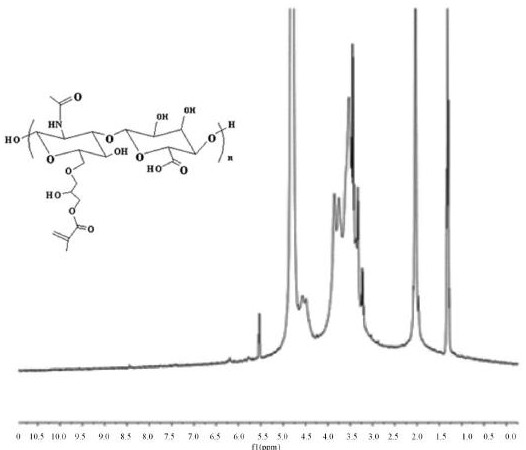

[0064] Hyaluronic acid and glycidyl methacrylate were fed at a ratio of 8:1 for grafting reaction to prepare modified hyaluronic acid, and the grafting rate of glycidyl methacrylate was 3%. The reaction chemical formula is as follows:

[0065] .

[0066] The nuclear magnetic spectrum obtained by nuclear magnetic resonance (NMR) of the prepared modified hyaluronic acid is as follows: image 3 shown. Depend on image 3 It can be seen that glycidyl methacrylate has been grafted onto the hyaluronic acid. Observe the modified hyaluronic acid under a scanning electron microscope (SEM), and the magnification of 100× is as follows Figure 4 As shown, the multiples of 1000× are as Figure 5 shown. Depend on Figure 4 with Figure 5 It can be seen that the modified hyaluronic acid has a porous fiber structure, can absorb water, and has good hydrophilicity.

[0067] Recombinant mussel fibroin-151 (fp-151) was constructed by in vitro recombinant protein technology. The fp-151 u...

Embodiment 2

[0071] Hyaluronic acid and glycidyl methacrylate were fed at a ratio of 5:1 for grafting reaction to prepare modified hyaluronic acid, and the grafting rate of glycidyl methacrylate was 8%.

[0072] The recombinant mussel fibroin-151 (fp-151) was constructed by in vitro recombinant protein technology, and the recombinant mussel filaggrin-151 was modified to obtain a modified mussel adhesion with a catechol grafting rate of 3%. protein.

[0073] The ruthenium terpyridine and sodium persulfate were formulated into a photoinitiator mixed solution in a ratio of 1:2.

[0074] The modified hyaluronic acid, the initiator mixture and the modified mussel adhesion protein were respectively encapsulated in the three channels of a simple three-component glue gun, the outlet of the simple glue gun was cut, and the three channels were squeezed manually according to the mark. The component mixture is applied to the defect site, wherein the molar ratio of modified hyaluronic acid: modified m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com