Breathable facing mortar

A technology of facing mortar and yellow sand, which is applied in the field of building materials, can solve problems such as poor air permeability, and achieve the effects of easy falling off, excellent air permeability, and good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

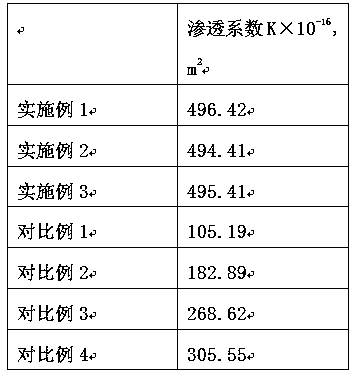

Examples

Embodiment 1

[0018] A breathable finishing mortar, made of the following ingredients in parts by weight: Portland cement 50, yellow sand 88, modified styrene-acrylic emulsion 15, methyl cellulose 12, polypropylene fiber 3, vitrified microbeads 6, Silane coupling agent 0.3, fly ash 10, melamine water reducer 1.2, water 55, polytrimethylene carbonate modified zeolite powder 5.5.

[0019] Further, the preparation method of the modified styrene-acrylic emulsion is:

[0020] Weigh 3.8% of the mass of styrene-acrylic emulsion silicone oil, slowly drop into the styrene-acrylic emulsion, keep the reaction temperature at 68°C, stir at a speed of 120r / min, and then add ammonium peroxide of 0.3% of the mass of the styrene-acrylic emulsion to adjust the temperature of the system The pH value is 6.4, stir at a high speed of 3000r / min for 40min, then cool naturally to room temperature, and then adjust the pH of the system to 8.5 to obtain the product;

[0021] The styrene-acrylic emulsion has a solid c...

Embodiment 2

[0030] A breathable finishing mortar, made of the following components in parts by weight: Portland cement 60, yellow sand 95, modified styrene-acrylic emulsion 30, methyl cellulose 14, polypropylene fiber 5, vitrified microbeads 8, Silane coupling agent 0.5, fly ash 14, melamine water reducer 1.4, water 60, polytrimethylene carbonate modified zeolite powder 6.2.

[0031] Further, the preparation method of the modified styrene-acrylic emulsion is:

[0032] Weigh 3.8% of the mass of styrene-acrylic emulsion silicone oil, slowly drop into the styrene-acrylic emulsion, keep the reaction temperature at 68°C, stir at a speed of 120r / min, and then add ammonium peroxide of 0.3% of the mass of the styrene-acrylic emulsion to adjust the temperature of the system The pH value is 6.4, stir at a high speed of 3000r / min for 40min, then cool naturally to room temperature, and then adjust the pH of the system to 8.5 to obtain the product;

[0033] The styrene-acrylic emulsion has a solid co...

Embodiment 3

[0042] A breathable finishing mortar, made of the following ingredients in parts by weight: Portland cement 55, yellow sand 92, modified styrene-acrylic emulsion 20, methyl cellulose 13, polypropylene fiber 4, vitrified beads 7, Silane coupling agent 0.4, fly ash 12, melamine water reducer 1.3, water 58, polytrimethylene carbonate modified zeolite powder 5.8.

[0043] Further, the preparation method of the modified styrene-acrylic emulsion is:

[0044] Weigh 3.8% of the mass of styrene-acrylic emulsion silicone oil, slowly drop into the styrene-acrylic emulsion, keep the reaction temperature at 68°C, stir at a speed of 120r / min, and then add ammonium peroxide of 0.3% of the mass of the styrene-acrylic emulsion to adjust the temperature of the system The pH value is 6.4, stir at a high speed of 3000r / min for 40min, then cool naturally to room temperature, and then adjust the pH of the system to 8.5 to obtain the product;

[0045] The styrene-acrylic emulsion has a solid conten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com