Porous electrode material with three metal Cu-Co-Mo/foamed nickel and preparation method and application of porous electrode material

A porous electrode, nickel foam technology, applied in the direction of electrode, electrode shape/type, electrolysis process, etc., can solve the problems of low catalytic activity, low specific surface area, low conductivity, etc., to improve catalytic activity, simple preparation process, excellent performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

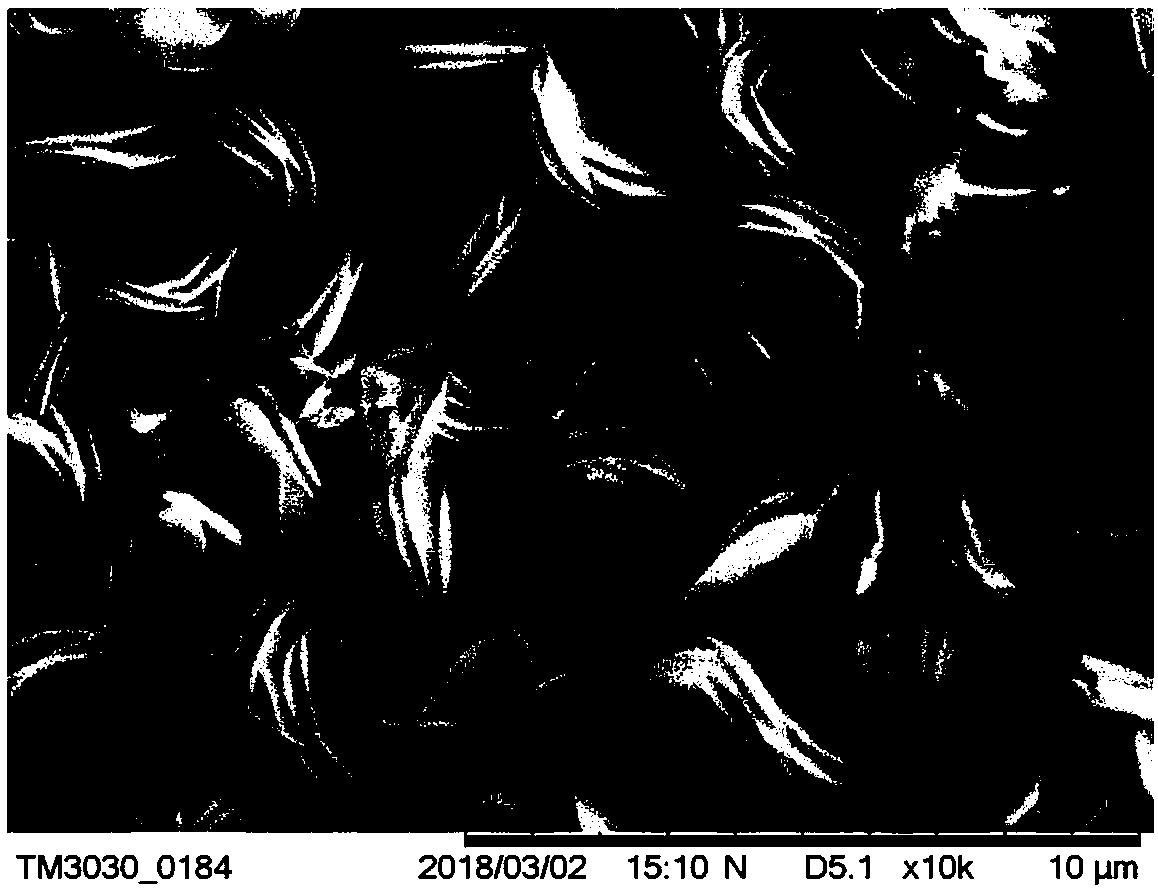

Image

Examples

Embodiment 1

[0032] The preparation method of the present invention possesses trimetallic Cu-Co-Mo / nickel foam porous electrode material specifically comprises the following steps:

[0033] a. Pretreatment of conductive substrate

[0034] Select the cut 1×1cm 2 Soak nickel foam in methanol, ethanol, tetrahydrofuran, chloroform and one or more solvents for ultrasonic treatment for 10-50 minutes, and then use hydrochloric acid solution for ultrasonic treatment for 15 minutes to chemically remove oil and surface oxides; The nickel substrate was rinsed with ionized water, and the concentration of hydrochloric acid used was 1mol / L.

[0035] b. Growth of hydrothermal synthesis products on nickel foam

[0036] CuCl was hydrothermally 2 , Co(NO 3 ) 2 、Na 2 MoO 4 Three kinds of precursor materials were dissolved in 50mL deionized water to obtain copper, cobalt, and molybdenum salt compound precursor solution, wherein the molar ratio of Cu, Co, and Mo three elements was 1:1:0.25, and the foam...

Embodiment 2

[0041] Step a is the same as embodiment 1

[0042] b. Growth of hydrothermal synthesis products on nickel foam

[0043] CuCl was hydrothermally 2 , Co(NO 3 ) 2 、Na 2 MoO 4 Three kinds of precursor materials were dissolved in 50mL deionized water to obtain copper, cobalt, and molybdenum salt compound precursor solution, wherein the molar ratio of Cu, Co, and Mo three elements was 1:1:0.5, and the foam after the above pretreatment Nickel is placed together in an autoclave for closed reaction, the reaction temperature is 180°C, and the reaction time is 8 hours. After the reaction is completed, the product is washed and dried.

[0044] c. High temperature calcination reduction of hydrothermal synthesis products

[0045] The nickel foam with the hydrothermal synthesis product grown on the above surface was heated in 5% H 2 / 95% Ar atmosphere at 500°C for 5 hours, followed by natural cooling to obtain a Cu-Co-Mo trimetallic porous electrolytic water catalyst, that is, a trime...

Embodiment 3

[0048] Step a is the same as embodiment 1

[0049] b. Growth of hydrothermal synthesis products on nickel foam

[0050] CuCl was hydrothermally 2 , Co(NO 3 ) 2 、Na 2 MoO 4 Three kinds of precursor materials were dissolved in 50mL deionized water to obtain copper, cobalt, and molybdenum salt compound precursor solution, wherein the molar ratio of Cu, Co, and Mo three elements was 1:1:1, and the foam after the above pretreatment Nickel is placed together in an autoclave for closed reaction, the reaction temperature is 180°C, and the reaction time is 8 hours. After the reaction is completed, the product is washed and dried.

[0051] c. High temperature calcination reduction of hydrothermal synthesis products

[0052] The nickel foam with the hydrothermal synthesis product grown on the above surface was heated in 5% H 2 / 95%Ar atmosphere at 500°C for 5h, followed by natural cooling to obtain a Cu-Co-Mo trimetallic porous electrolytic water catalyst, that is, a trimetallic C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com