Catalyst for treating waste gas generated by roasting silicoaluminophosphate molecular sieve and preparation method thereof

A silicon-aluminum-phosphorus molecular sieve and catalyst technology is applied in the field of chemical industry, waste gas treatment in the roasting process of silicon-aluminum-phosphorus molecular sieve, and can solve problems such as harsh environmental conditions, crowd hazards, air pollution, etc., achieving high mechanical strength, easy processing and filling, Highly selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

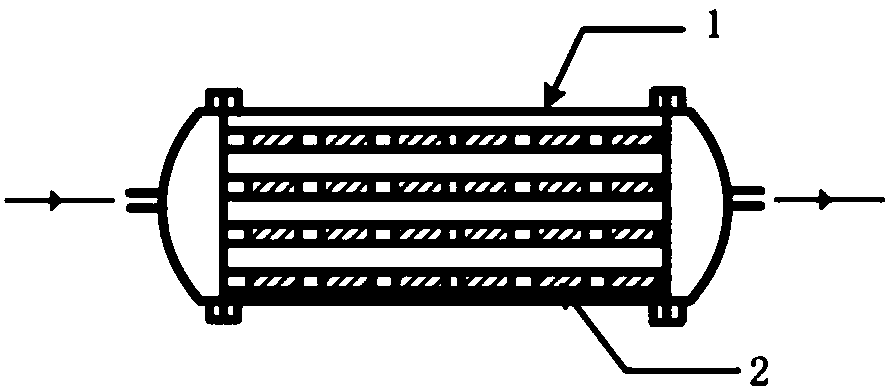

[0028] A catalyst for treating exhaust gas in the roasting of silicon aluminum phosphorus molecular sieves, including a substrate support, a carrier coating and a loaded active component. The outer layer of the substrate support is a carrier coating, and most of the loaded active components are attached to the carrier The outer layer of the coating, only a small amount will enter the interior of the washcoat.

[0029] The substrate support is composed of ceramics, cordierite, and silicon carbide; the carrier coating is composed of an alumina coating with a composite oxide of lanthanum oxide and cerium oxide; the active components of the load are palladium oxide and ruthenium. mixture of oxides.

[0030] The cross-section of the substrate support body is a regular hexagon, and the interior of the substrate support body is penetrated by a passage whose cross-section is circular.

[0031] This case also protects a preparation method of the above-mentioned catalyst, which is prep...

Embodiment 2

[0037] A catalyst for treating exhaust gas in the roasting of silicon aluminum phosphorus molecular sieves, including a substrate support, a carrier coating and a loaded active component. The outer layer of the substrate support is a carrier coating, and most of the loaded active components are attached to the carrier The outer layer of the coating, only a small amount will enter the interior of the washcoat.

[0038] The substrate support is composed of silicon carbide, silicon dioxide, and alumina; the carrier coating is composed of an alumina coating of a composite oxide added with tin oxide and yttrium oxide; the active component of the load is platinum oxide, A mixture of rhodium oxides.

[0039] The cross-section of the substrate support body is a regular square, and the interior of the substrate support body is penetrated by a passage whose cross-section is triangular.

[0040] This case also protects a preparation method of the above-mentioned catalyst, which is prepa...

Embodiment 3

[0046] A catalyst for treating exhaust gas in the roasting of silicon aluminum phosphorus molecular sieves, including a substrate support, a carrier coating and a loaded active component. The outer layer of the substrate support is a carrier coating, and most of the loaded active components are attached to the carrier The outer layer of the coating, only a small amount will enter the interior of the washcoat.

[0047] The substrate support is composed of spinel and mullite; the carrier coating is composed of alumina coating with composite oxides of yttrium oxide and cobalt oxide; the active components of the load are palladium oxide, gold oxide mixture of things.

[0048] The cross-section of the substrate support body is a regular hexagon, and the interior of the substrate support body is penetrated by a passage with a square cross-section.

[0049] This case also protects a preparation method of the above-mentioned catalyst, which is prepared by the following method:

[0050...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com