Preparation method of inorganic and organic coated rutile titanium dioxide

A rutile-type titanium dioxide coating technology, applied in the field of materials, can solve the problems of poor coating effect of titanium dioxide coating, low intelligence, complex production process of titanium dioxide, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

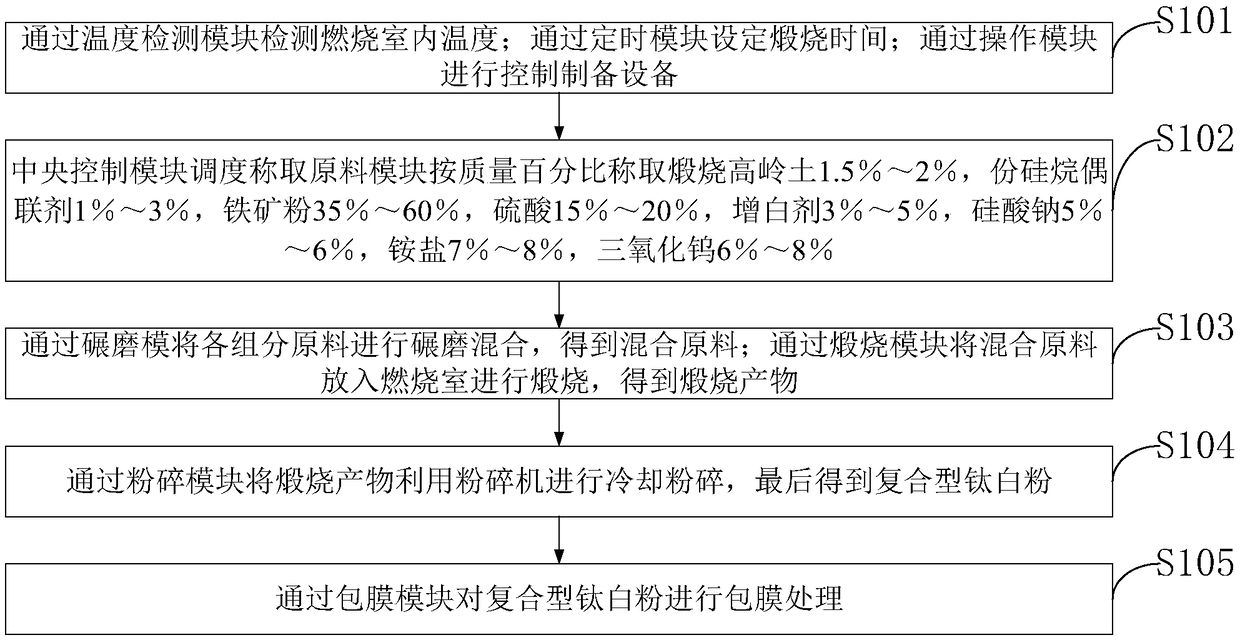

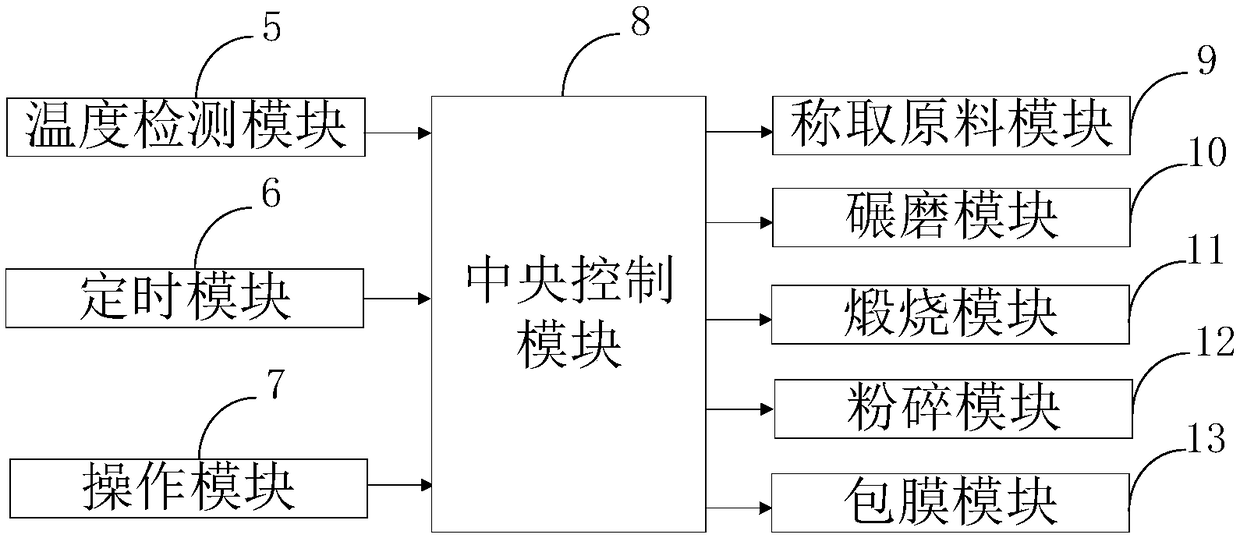

[0107] Such as figure 1 As shown, the preparation method of the surface inorganic and organic coated rutile titanium dioxide provided by the embodiment of the present invention comprises the following steps:

[0108] S101, detecting the temperature in the combustion chamber through the temperature detection module; setting the calcination time through the timing module; controlling the preparation equipment through the operation module;

[0109] S102, the central control module dispatches and weighs the raw material module weighs 1.5% to 2% of calcined kaolin, 1% to 3% of silane coupling agent, 35% to 60% of iron ore powder, and 15% to 20% of sulfuric acid according to mass percentage, Whitening agent 3%-5%, sodium silicate 5%-6%, ammonium salt 7%-8%, tungsten trioxide 6%-8%;

[0110] S103, grinding and mixing the raw materials of each component through a grinding mold to obtain a mixed raw material; putting the mixed raw material into a combustion chamber through a calcinat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com