Eu<2+> and Eu<3+> europium ion mixed activated fluorescent powder, preparation method and application

A europium ion and phosphor technology, applied in the field of inorganic light-emitting materials, can solve the problems of unreported multi-color light-emitting phosphors, and achieve the effects of good physical and chemical properties, thermal stability, good structural rigidity and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] According to the chemical formula Na 1.94 Eu 0.06 al 2 B 4 o 10 The stoichiometric ratio of each cationic element in the formula was weighed respectively for the reactant raw materials: sodium nitrate NaNO3: 1.65 grams, europium nitrate Eu(NO3)3 6H2O: 0.268 grams, aluminum nitrate Al(NO3) 3 9H2O: 7.5 grams, boric acid H3BO3: 2.48 grams, respectively dissolve them in dilute nitric acid, add appropriate amount of deionized water, weigh appropriate amount of complexing agent citric acid, add 1.19 grams of citric acid to each solution, and magnetically stir in a water bath at 70 °C Obtain a clear solution, then mix each reaction solution evenly, place in an oven, and dry to obtain a precursor; then place the precursor in a muffle furnace for calcination at a sintering temperature of 700°C for 10 hours and cool to room temperature , take out and fully grind to get the sample, its structural formula is Na 1.94 Eu 0.06 al 2 B 4 o 10 .

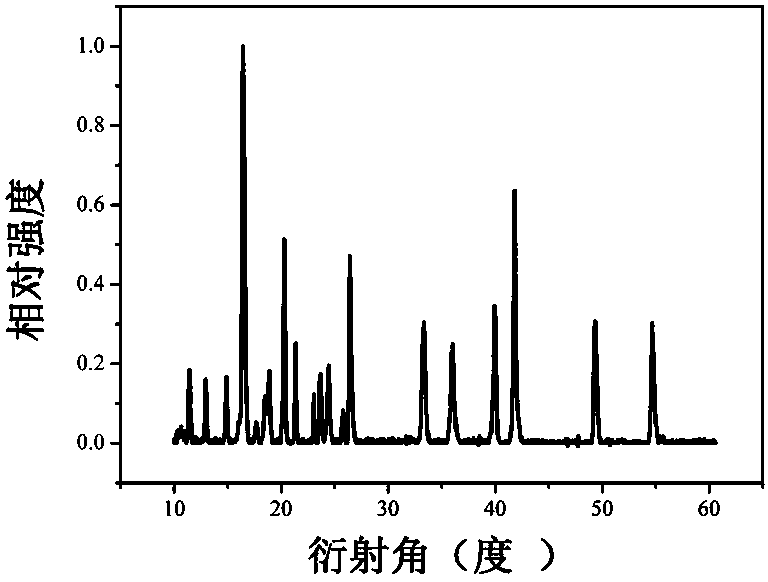

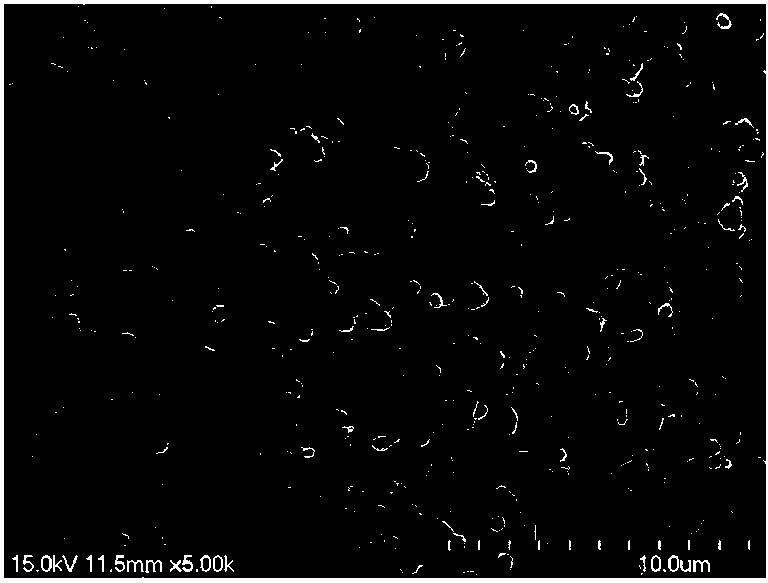

[0026] See attached figure 1 ...

Embodiment 2

[0031] According to the chemical formula Na 1.98 Eu 0.02 Al 2 B 4 o 10 The stoichiometric ratio of each cationic element in the medium is weighed respectively for sodium carbonate Na 2 CO 3 : 1.05 g, europium nitrate Eu (NO 3 ) 3 •6H 2 O: 0.01 g, aluminum nitrate Al(NO 3 ) 3 •9H 2 O: 7.5 g, boric acid H 3 BO 3 : 2.48 grams, take an appropriate amount of complexing agent citric acid, dissolve the above reagents in dilute nitric acid respectively, and add an appropriate amount of deionized water, then add 1.656 grams of citric acid, and magnetically stir in a water bath at 90 ° C to obtain a clear solution; Mix the obtained reaction solution and place it in an oven, dry it to obtain the precursor, put the precursor in a muffle furnace for calcination, the sintering temperature is 850°C, the calcination time is 3 hours, cool to room temperature, take it out and grind it thoroughly A sample is obtained. Its structural properties, excitation spectrum and embodiment 1 ...

Embodiment 3

[0034] According to the chemical formula Na 1.998 Eu 0.002 Al 2 B 4 o 10 The stoichiometric ratio of each cationic element in the medium, respectively weigh sodium nitrate NaNO 3 : 1.69 g, europium oxide Eu 2 o 3 : 0.004 g, aluminum hydroxide Al(OH) 3 : 1.56 g, boron trioxide B 2 o 3 : 1.4 grams, the above reagents were dissolved in dilute nitric acid, added appropriate amount of deionized water, and 1.6 grams of citric acid was added, magnetically stirred in a water bath at 80 ° C to obtain a clear solution; the reaction solutions were mixed and placed in an oven, The precursor was obtained by drying, and the precursor was calcined in a muffle furnace at a sintering temperature of 800°C for 5 hours, cooled to room temperature, taken out and fully ground to obtain a sample.

[0035] The structure, property and excitation spectrum of the sample prepared in this example are similar to Example 1.

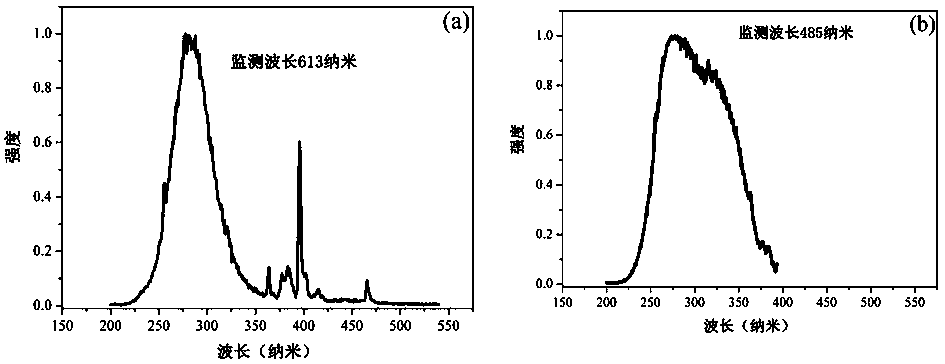

[0036] See attached Figure 6 , is the fluorescence spectrum of the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com