Chemical palladium plating solution, and preparation method, application method and applications thereof

An electroless plating, palladium ion technology, applied in liquid electroless plating, metal material coating process, coating and other directions, can solve the problems of electrochemical corrosion of circuit boards, unfavorable production operations, easy precipitation of Pd, etc., to avoid corrosion, The appearance is flat, easy to store and transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

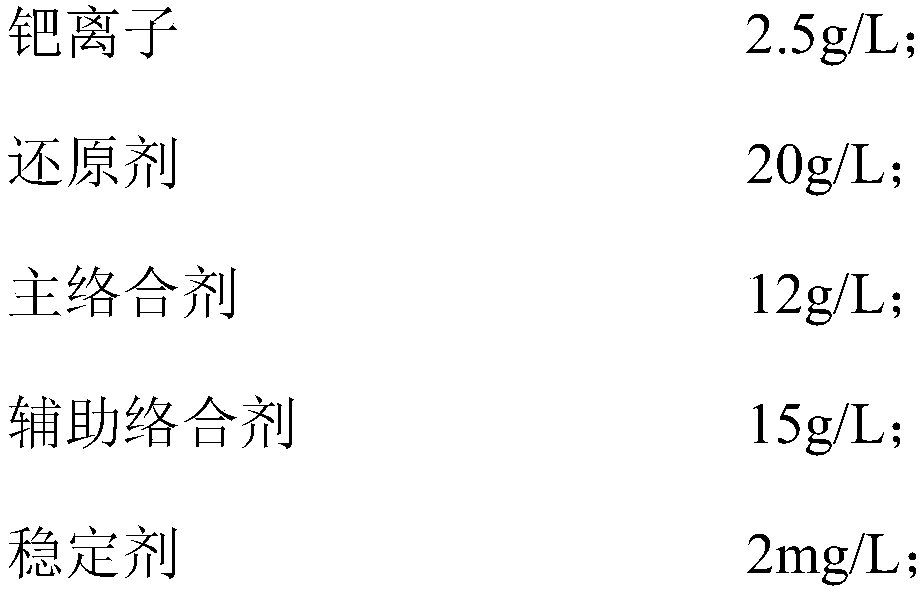

[0044] A kind of electroless palladium plating solution, by the total volume of electroless palladium plating solution, comprises following component:

[0045]

[0046]

[0047] Among them, the palladium ion is provided by palladium tetraammonium sulfate, the reducing agent is sodium hypophosphite, the main complexing agent is ethylenediamine, the auxiliary complexing agent is acrylic acid, the stabilizing agent is thiourea, the pH buffering agent is borax and boric acid, and the pH buffering agent is The pH value of the electroless palladium plating solution is 7.5.

[0048] The preparation method is as follows:

[0049] Add tetraammine palladium sulfate, main complexing agent, auxiliary complexing agent, reducing agent, stabilizing agent and pH buffering agent into water in a formulated amount, and mix uniformly to obtain an electroless palladium plating solution.

preparation example 2

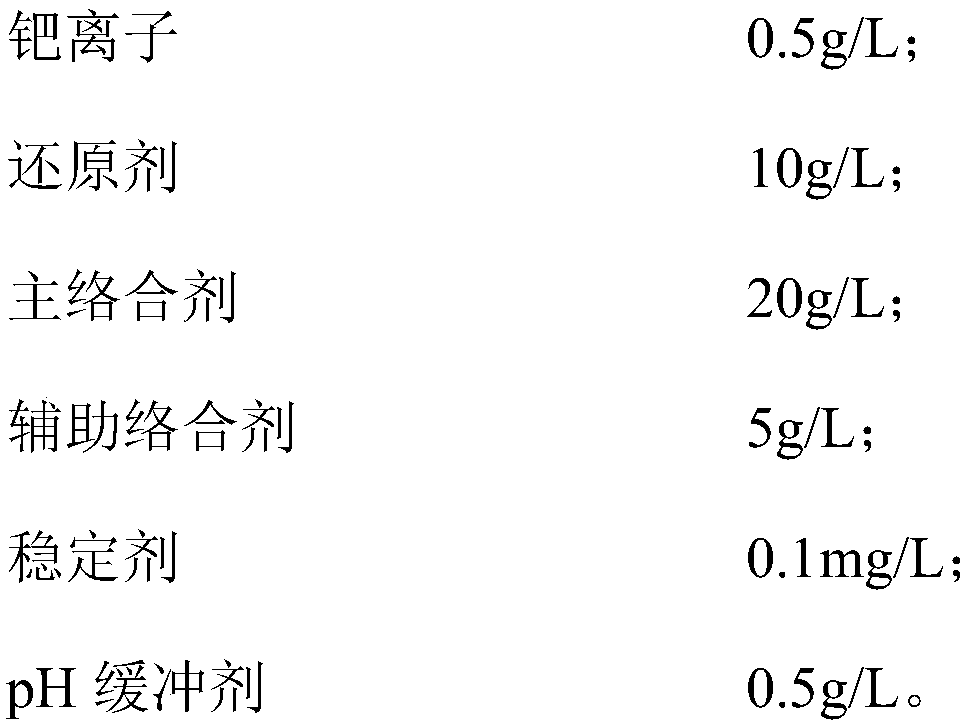

[0051] A kind of electroless palladium plating solution, by the total volume of electroless palladium plating solution, comprises following component:

[0052]

[0053] Among them, the palladium ion is provided by palladium tetraammonium sulfate, the reducing agent is sodium hypophosphite, the main complexing agent is ethylenediamine, the auxiliary complexing agent is oxalic acid, the stabilizing agent is thiourea, and the pH buffering agent is sodium dihydrogen phosphate and phosphoric acid Sodium hydrogen disodium, a pH buffering agent to adjust the pH value of the electroless palladium plating solution to 6.9.

[0054] The preparation method is as follows:

[0055] Add tetraammine palladium sulfate, main complexing agent, auxiliary complexing agent, reducing agent, stabilizing agent and pH buffering agent into water in a formulated amount, and mix uniformly to obtain an electroless palladium plating solution.

preparation example 3

[0057] A kind of electroless palladium plating solution, by the total volume of electroless palladium plating solution, comprises following component:

[0058]

[0059] Wherein, the palladium ion is provided by palladium tetraammonium sulfate, the reducing agent is a composition composed of sodium hypophosphite and formic acid in any ratio, the main complexing agent is sodium edetate, the auxiliary complexing agent is malic acid, and the stabilizer is Bismuth nitrate, the pH buffering agent is sodium dihydrogen phosphate and disodium hydrogen phosphate, and the pH buffering agent stabilizes the pH value of the electroless palladium plating solution to 6.5.

[0060] The preparation method is as follows:

[0061] Add tetraammine palladium sulfate, main complexing agent, auxiliary complexing agent, reducing agent, stabilizing agent and pH buffering agent into water in a formulated amount, and mix uniformly to obtain an electroless palladium plating solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com