Method for preparing self-doped Fe-N-C oxygen reduction electrocatalyst through animal blood salting-out thermal polymerization

An electrocatalyst and thermal polymerization technology, applied in the field of electrocatalysis, achieves the effects of excellent electrocatalytic performance, increased pores, and reduced air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) Take about 500mL of fresh pig blood in a 1L beaker, heat and dry in a drying oven at 80°C until constant weight.

[0046] (2) Crush the dried fresh pig blood, pass through a 200-mesh sieve, and take about 1.00 g of the under-sieved powder into the corundum ark.

[0047] (3) Put the corundum ark in a tube furnace for high-temperature pyrolysis, at a heating rate of 10°C / min, high-temperature pyrolysis at 900°C for 60 minutes, and cool to room temperature.

[0048] (4) The pyrolyzed material was pulverized and fully washed with a large amount of mixed solution of deionized water and ethanol, and then freeze-dried (19Pa, -50°C) to obtain a catalyst.

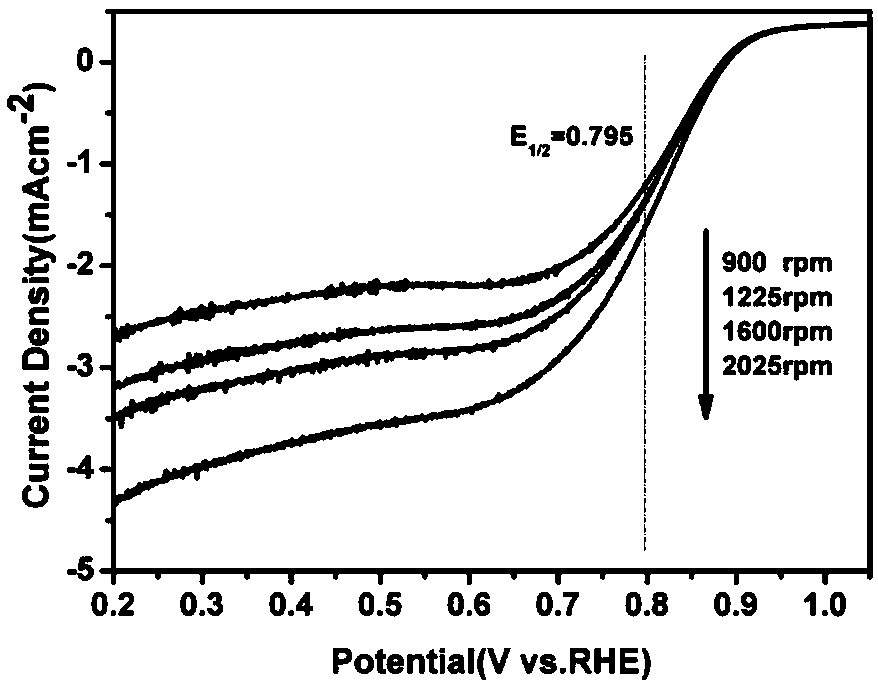

[0049] (5) Electrocatalytic performance test: Weigh 9 mg of the prepared catalyst and a 2.0 mL centrifuge tube with an electronic balance, add 0.99 mL of absolute ethanol and 0.01 mL of 5% Nafion ethanol solution, and sonicate for 20 min-60 min to form a uniform dispersion. Take 10ul of dispersion liquid and drop-coat it...

Embodiment 2

[0052] (1) Take about 500mL of fresh pig blood in a 1L beaker to which 200mL of 50g / L sodium chloride solution has been added in advance, stir and let stand for 30min.

[0053] (2) Boil the pig blood after salting out in a 2.5L beaker with water for 20min, take it out and dry it at 80°C.

[0054] (3) Put the corundum ark in a tube furnace for high-temperature pyrolysis, at a heating rate of 10°C / min, high-temperature pyrolysis at 900°C for 60 minutes, and cool to room temperature.

[0055] (4) The pyrolyzed material was pulverized and fully washed with a large amount of mixed solution of deionized water and ethanol, and then freeze-dried (19Pa, -50°C) to obtain a catalyst.

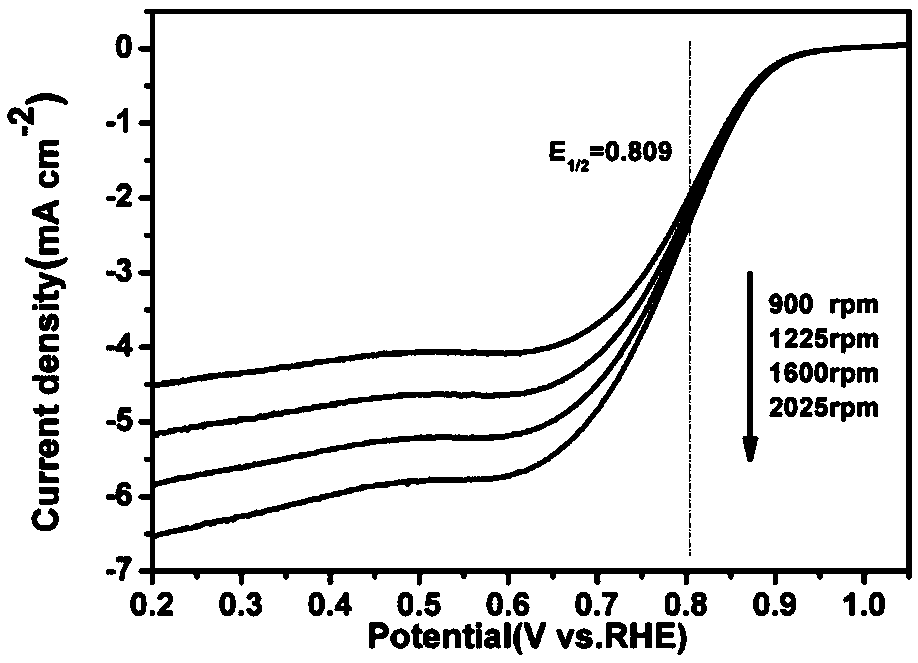

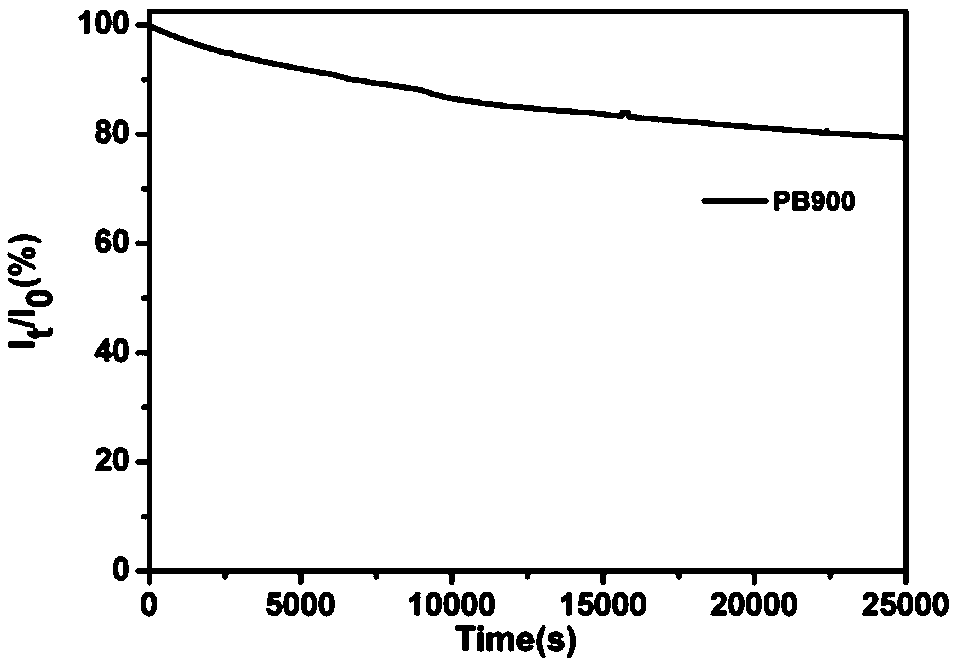

[0056] (5) Electrocatalytic performance test: perform the performance test according to the method described in step 5 in Example 1, and the specific oxygen reduction catalytic performance is as follows figure 2 As shown, the stability test as image 3 shown. At the same time, the electrocatalytic oxyg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com