Device and method for forming and separating elemental sulfur in situ

An elemental sulfur, in-situ technology, applied in sterilization methods, methods of supporting/immobilizing microorganisms, chemical instruments and methods, etc., can solve problems such as drainage pipeline corrosion, low elemental sulfur generation rate, and poisoning water organisms.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

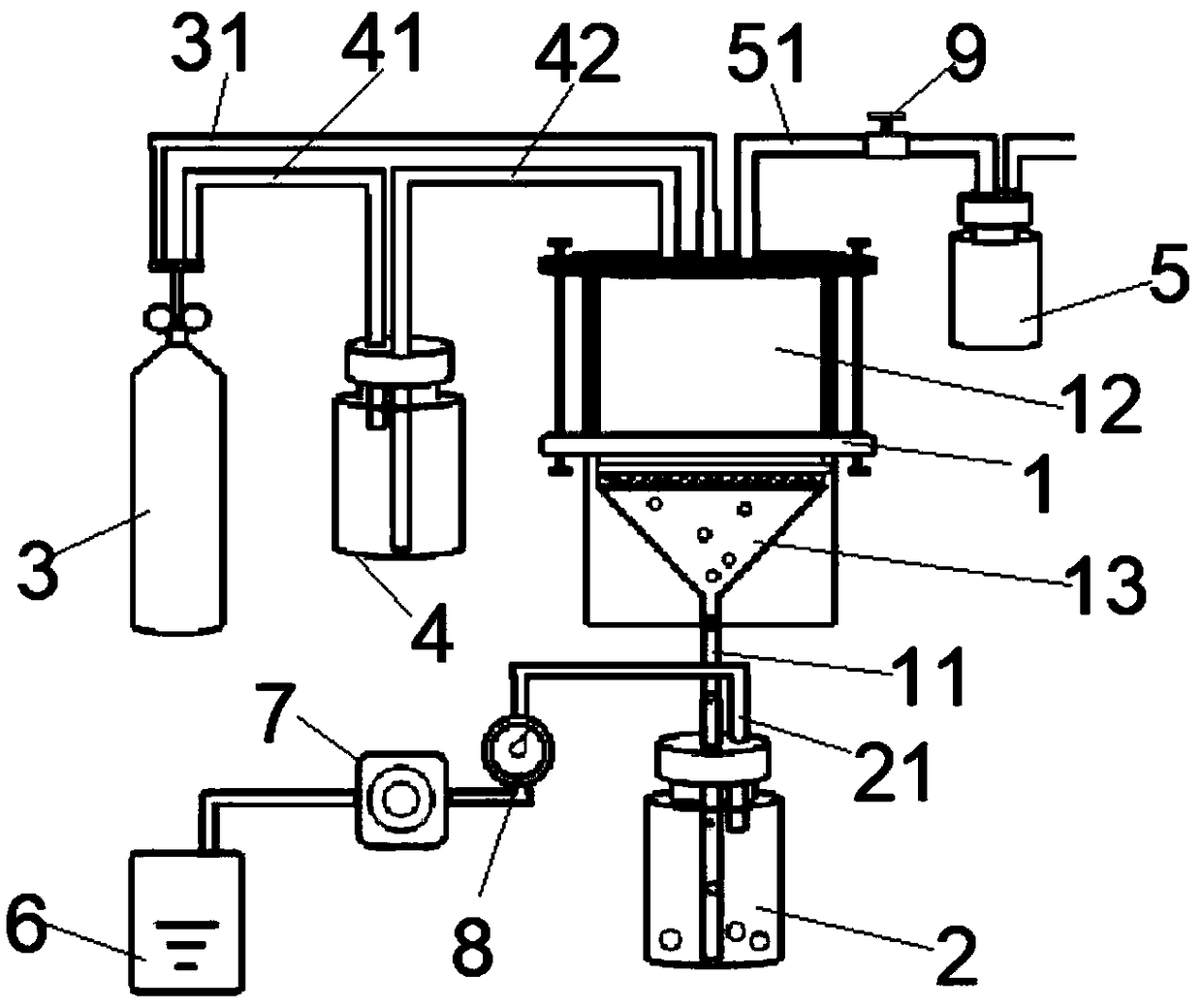

[0036] Such as figure 1 As shown, a device for forming and separating elemental sulfur in situ of the present invention includes a reaction device 1, a liquid collection device 2, an argon gas cylinder 3, a feeding device 4, a gas collection device 5, a water storage device 6, a pump 7. Pressure gauge 8; the reaction device 1 is a biofilm-microfiltration membrane composite reaction device, and the liquid collection device 2 is arranged below the reaction device 1, and the liquid collection device 2 can collect the elemental sulfur generated by the reaction device 1; The steel cylinder 3 is connected to the reaction device 1 through the first pipeline 31, and the argon gas cylinder 3 can feed argon gas into the reaction device 1 to ensure that the reaction device 1 is always in a completely anaerobic environment, and also to ensure the internal and external pressure of the reaction device 1 system. be consistent.

[0037] A feeding device 4 is also arranged between the argon c...

Embodiment 2

[0043] A method for forming and separating elemental sulfur in situ, comprising the following steps:

[0044] S1. Pass inert gas such as argon into the reaction device to keep the reaction device in an anaerobic state;

[0045] S2, the reaction device is provided with a separation membrane, the separation membrane is a biofilm-microfiltration membrane double-layer structure, the flow direction of the liquid in the reaction device is to flow through the biofilm first, and then pass through the microfiltration membrane. Sulfur-oxidizing bacteria first contact the wastewater to be treated with the biofilm to generate nitrogen and carbon dioxide gas and elemental sulfur solids on the biofilm;

[0046] S3. The nitrogen and carbon dioxide gas in the reaction device is discharged and collected, and the elemental sulfur generated on the biofilm is separated from the biofilm through the microfiltration membrane, and the microfiltration membrane prevents the passage of sulfur-oxidizing ...

Embodiment 3

[0051] In this embodiment, on the basis of the second embodiment, a driving device such as a peristaltic pump is added to the method, which can drive the wastewater to flow through the biofilm and the microfiltration membrane in sequence.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com