Adjustable biological membrane-activated sludge sewage treatment method and adjustable biological membrane-activated sludge sewage treatment device

A sewage treatment method and sewage treatment device technology, applied in biological sludge treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of redundant and insufficient facilities, and achieve high nitrogen removal Phosphorus capacity, enhanced nitrogen and phosphorus removal capacity, enhanced adsorption and removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

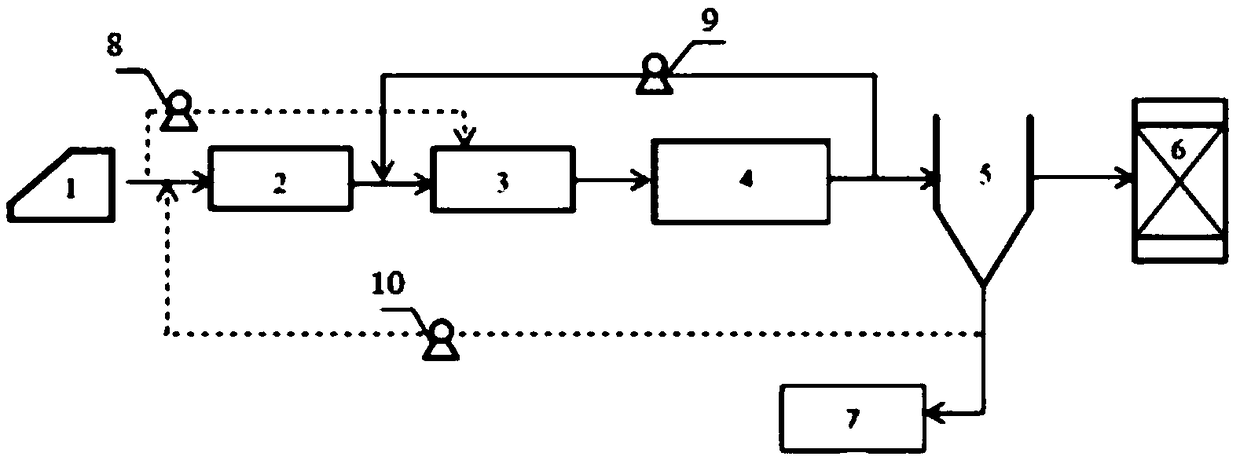

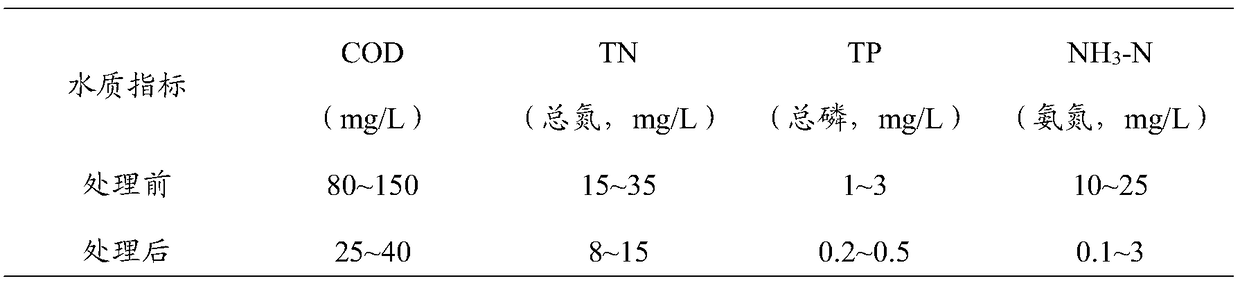

[0093] Simulate the inflow of low-concentration sewage (COD is 80-150mg / L) in summer in southern China, and carry out sewage treatment according to the following steps:

[0094] Step 1: Sewage is subjected to grid grit pretreatment in grid grit chamber 1 to remove slag with larger particle size to obtain pretreated sewage;

[0095] Step 2: open the mud-water mixed liquid return pump 9, close the water inlet distribution pump 8 and the sludge return pump 10, and deliver the pretreated sewage to the anaerobic pond / regulating pond 2 (the anaerobic pond / regulating pond serves as In the use of the regulating tank), the sewage and the silt are further separated; the obtained sewage and the return mud-water mixture are transported to the anoxic tank 3 for anoxic treatment, the hydraulic retention time is 3h, and the dissolved oxygen is 0.2mg / L. Anoxic pool effluent;

[0096] Step 3: Transport the effluent from the anoxic pool to the aerobic pool 4 for aerobic treatment. The filling ...

Embodiment 2

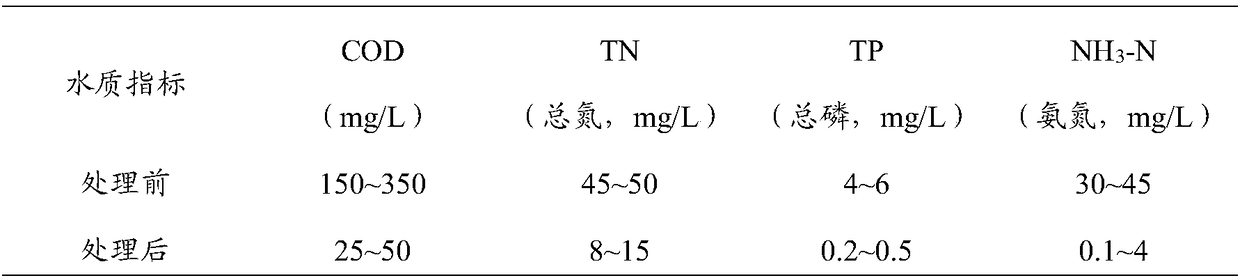

[0106] Simulate the inflow of low-concentration sewage in summer in the north or high-concentration sewage (COD is 150-350mg / L) in winter in the south, and carry out sewage treatment according to the following steps:

[0107] Step 1: Sewage is subjected to grid grit pretreatment in grid grit chamber 1 to remove slag with larger particle size to obtain pretreated sewage;

[0108] Step 2: Turn on the water inlet distribution pump 8, the mud-water mixture return pump 9 and the sludge return pump 10, and transport 80% of the pretreated sewage and return sedimentation sludge to the anaerobic tank / adjustment tank 2 by volume Anaerobic treatment is carried out in the above-mentioned anaerobic pool / conditioning pool as the anaerobic pool), and the hydraulic retention time is 2h to obtain the effluent of the anaerobic pool;

[0109] The effluent from the anaerobic tank, the reflux mud-water mixture and 20% pretreated sewage are transported to the anoxic tank 3 for anoxic treatment, the...

Embodiment 3

[0120] Simulate the inflow of high-concentration sewage (COD is 350-700mg / L) in northern winter, and carry out sewage treatment according to the following steps:

[0121] Step 1: Sewage is subjected to grid grit pretreatment in grid grit chamber 1 to remove slag with larger particle size to obtain pretreated sewage;

[0122] Step 2: Turn on the water inlet distribution pump 8, the mud-water mixture return pump 9 and the sludge return pump 10, and transport 95% of the pretreated sewage and the return sedimentation sludge to the anaerobic tank / adjustment tank 2 by volume Anaerobic treatment is carried out in the anaerobic pond / adjustment pond as described in the anaerobic pond), and the hydraulic retention time is 1.6h to obtain the effluent of the anaerobic pond;

[0123] The effluent from the anaerobic tank, the refluxed mud-water mixture and 5% pretreated sewage are transported to the anoxic tank 3 for anoxic treatment, the hydraulic retention time is 3 h, and the dissolved o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com