Nano cellulose hydrogel and aerogel and preparation method and application thereof

A technology of nanocellulose and hydrogel, applied in the application field of cellulose, can solve the problems of limiting the application of nanocellulose gel, long preparation cycle, high cost, etc., to achieve easy realization of large-scale production, broaden the breadth and depth, The effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

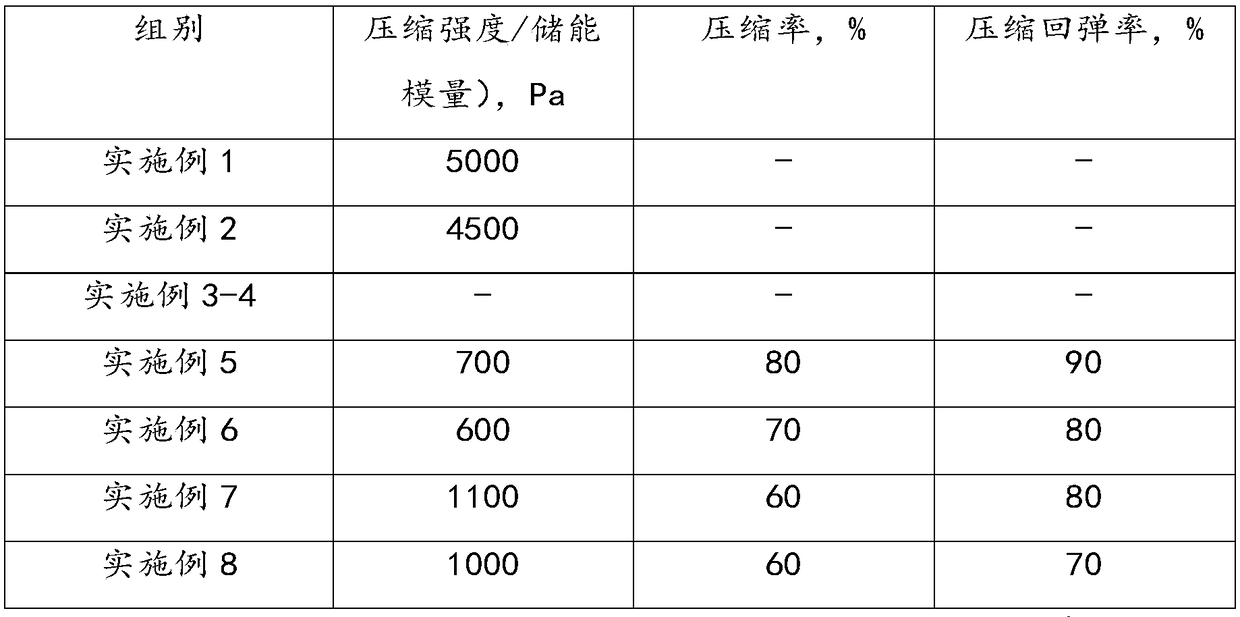

Examples

preparation example Construction

[0049] In a first aspect, in at least one embodiment, a method for preparing a nanocellulose hydrogel is provided, comprising the following steps:

[0050] (a) pre-treating the cellulose raw material to obtain a nanocellulose dispersion;

[0051] (b) the nanocellulose dispersion is mixed with a crosslinking agent to obtain a composite dispersion;

[0052] (c) subjecting the composite dispersion to freeze-thaw treatment to obtain nanocellulose hydrogel.

[0053]Cellulose is the most abundant organic compound found on Earth and is widely used due to its availability and sustainable production. An estimated 100 billion tons of cellulose are produced each year. Cellulose exhibits very attractive properties, such as biodegradability, biocompatibility, chemical and thermal stability, and limited carbon footprint; cellulose is also a renewable resource. Nanogels have many excellent properties due to their unique microscopic network structure, such as large specific surface area, h...

Embodiment 1

[0103] A preparation method of nanocellulose hydrogel, comprising the following steps:

[0104] (1) Treatment of cellulose raw material: use wood cellulose as raw material, mechanically disintegrate it into cotton wool, weigh 1g of the dry weight of the sample, 0.1g of NaBr, 0.016g of TEMPO and 100mL of distilled water into a beaker, stir evenly, and fully dissolve. Add 6mmol sodium hypochlorite to the system, add dropwise 5M hydrochloric acid to adjust the overall system pH to 10, and start oxidation. Use an automatic titrator to automatically add 0.5M sodium hydroxide dropwise to maintain the overall system pH at 10. When the system hardly consumed sodium hydroxide solution, a small amount of ethanol solution was added dropwise to plant the reaction, and a small amount of 0.5M hydrochloric acid was added to adjust the pH to neutral. The oxidized cellulose was cleaned by centrifugation, and the insoluble matter was stored in a refrigerator at 4°C.

[0105] (2) Preparation o...

Embodiment 2

[0108] A preparation method of nanocellulose hydrogel, comprising the following steps:

[0109] (1) Treatment of cellulose raw material: take hemp cellulose as raw material, take 1g of dry weight hemp cellulose and 64% sulfuric acid at 60°C for 3 hours under the condition of solid-liquid ratio of 1:30, and carry out thorough treatment on the material after the reaction is completed. Washed and dialyzed to obtain acid decomposed hemp cellulose.

[0110] (2) Preparation of nanocellulose: take 0.5g dry weight acid-lyzed hemp cellulose and add 100mL distilled water to homogenate, operate ultrasonically, and circulate 5-6 times until the solution is clear and transparent, centrifuge to remove the precipitate, and the supernatant is The prepared nanocellulose dispersion.

[0111] (3) Preparation of nanocellulose hydrogel: the nanocellulose prepared by the above steps is used as raw material, first the nanocellulose is adjusted to a solid content concentration of 0.4%, and then the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Storage modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com