Quartz stone slab and preparing method thereof

A technology of quartz stone plate and quartz powder, which is applied in the field of building materials, can solve the problems of affecting the service life of artificial quartz stone, low strength, easy cracking, etc., and achieve excellent waterproof performance and mechanical properties, increased strength, and low water absorption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

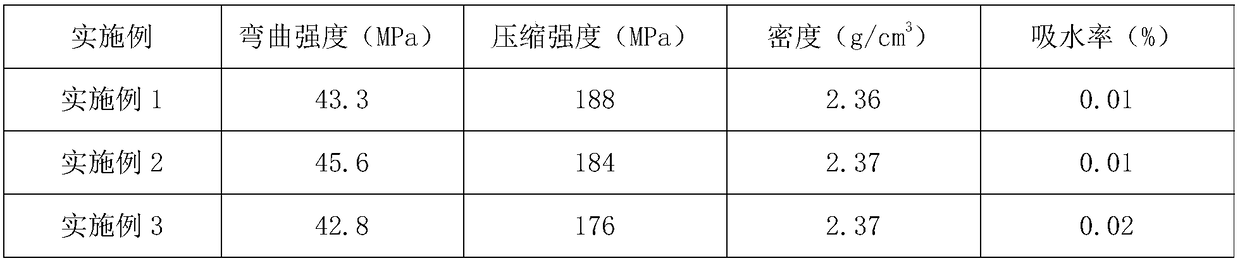

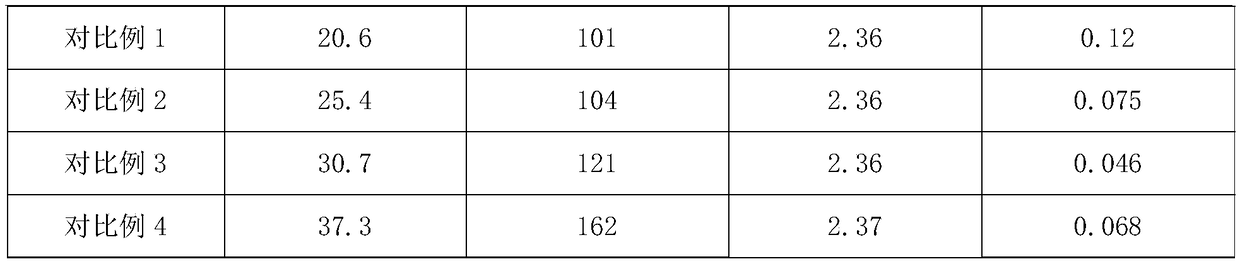

Examples

Embodiment 1

[0027] Under stirring at 50r / min, add 40% of quartz sand with a particle size of 60 mesh, 30% of quartz powder with a particle size of 300 mesh, 1% of silane coupling agent A151 vinyl triethoxysilane, 1% of ferric chloride, Sodium polyacrylate 3%, isophthalic unsaturated polyester resin 5%, heavy calcium carbonate 15%, accelerator triethanolamine 2%, curing agent tert-butyl peroxybenzoate 0.5%, curing agent methyl ethyl ketone peroxide 2.5% , after the addition, increase the stirring speed to 200r / min, continue stirring for 10 minutes, and obtain the mixture after mixing; pour the mixture into the mold, and then press and form it under the vacuum degree of -0.1~-0.08Pa, after forming The solidified plate is solidified at 90°C. After the reaction is completed, it is demolded and cooled to obtain a quartz stone plate.

Embodiment 2

[0029] Under stirring at 80r / min, 42% of quartz sand with a particle size of 80 mesh, 28% of quartz powder with a particle size of 150 mesh, 2.5% of silane coupling agent KH550γ-aminopropyltriethoxysilane, and 3 %, sodium polyacrylate 5%, isophthalic unsaturated polyester resin 3%, polymethyl methacrylate resin 4%, heavy calcium carbonate 10%, accelerator cobalt isooctanoate 1% and curing agent cyclohexyl peroxide Ketone 1.5%, after the addition, increase the stirring speed to 150r / min, continue to stir for 20min, and get the mixture after mixing; pour the mixture into the mold, and then press to form under the vacuum degree of -0.1~-0.08MPa , The formed plate is cured at 95°C, after the reaction is finished, it is demoulded and cooled to obtain a quartz stone plate.

Embodiment 3

[0031] Under stirring at 60r / min, add 45% of quartz sand with a particle size of 10 mesh, 20% of quartz powder with a particle size of 100 mesh, 3% of silane coupling agent KH570 methacryloxypropyltrimethoxysilane, chlorine 1.5% iron oxide, 6% sodium polyacrylate, 13% polymethyl methacrylate resin, 10% heavy calcium carbonate, 1% accelerator triethanolamine and 0.5% curing agent methyl ethyl ketone peroxide. After adding, increase the stirring Speed up to 100r / min, continue to stir for 30 minutes, and get the mixture after mixing; pour the mixture into the mold, and then press and form it under the vacuum degree of -0.1~-0.08MPa, and the formed plate is cured at 92°C , After the reaction is finished, it is demolded and cooled to obtain a quartz stone plate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com