Electrode sheet for lithium metal battery, preparation method thereof, and lithium metal battery

A lithium metal battery and metal lithium sheet technology, which is applied to battery electrodes, non-aqueous electrolyte battery electrodes, secondary batteries, etc., can solve the problem of increasing the contact between the positive and negative electrodes of lithium batteries, poor thermal deformation resistance of the diaphragm, and local charge distribution Inhomogeneity problems, achieve low overpotential, good wettability, and inhibit dendrite growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The present invention also provides a method for preparing a negative electrode sheet for a lithium metal battery, comprising the following steps:

[0035] Under the condition of protective atmosphere, apply physical pressure to compound the sponge and lithium sheet to obtain the negative electrode sheet.

[0036] First, cut the sponge to the required thickness, and then cut it to get a certain size of sponge piece;

[0037] Then superimpose the sponge sheet and the lithium sheet, and apply physical pressure under the condition of protective atmosphere to obtain a composite sheet;

[0038] Wherein, the protective atmosphere condition is selected from argon atmosphere, and the water and oxygen content in the protective atmosphere are all less than 0.1ppm. In the present invention, the compression process of the sponge sheet and the lithium sheet is preferably carried out in a glove box. The present invention preferably employs a hydraulic encapsulation machine to apply...

Embodiment 1

[0062] Preparation of lithium metal battery with melamine sponge and metal lithium composite elastic interface material without diaphragm structure design and symmetric battery cycle test:

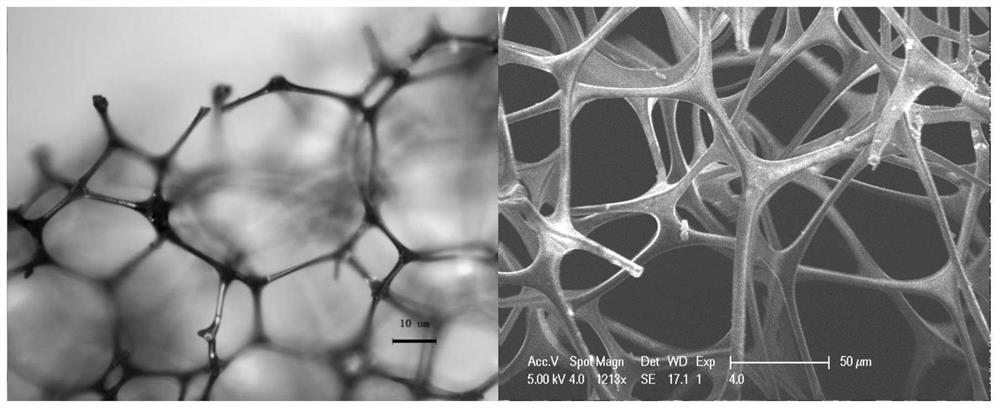

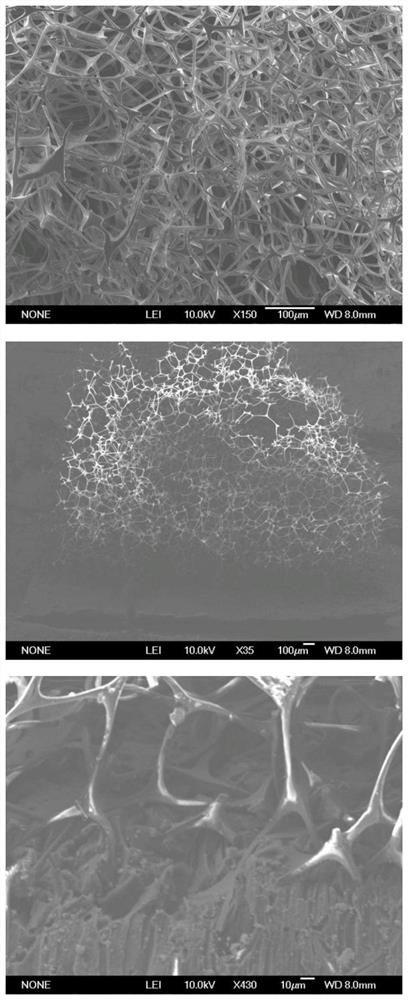

[0063] Cut the prepared clean sponge material with a scalpel to a thickness of 2.5mm; then use a punch to cut out a sponge disc with a diameter of 16mm; the density of the sponge is 0.01-0.02g / cm 3 , the porosity is 98% to 99%, and the pore diameter is 50 to 100 μm. see figure 1 , figure 1 It is the optical micrograph (left) and SEM picture (right) of the sponge material selected in Examples 1 and 2 of the present invention.

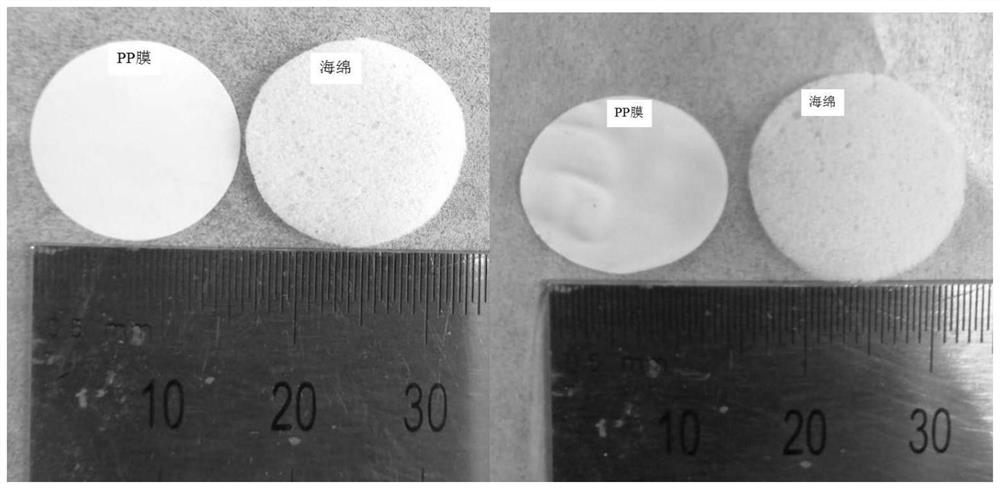

[0064] Put the sponge material at 150°C for 1 hour, and take pictures of its state and size before and after. The results are shown in figure 2 , figure 2 It is a comparison of the digital photos of the sponge material selected in Examples 1 and 2 of the present invention and the polypropylene diaphragm before being kept at 150° C. for 1 hour. figure 2 Among ...

Embodiment 2

[0074] Lithium metal battery preparation and half-cell coulombic efficiency test of sponge, metal lithium composite elastic interface material without diaphragm structure design:

[0075] The sponge with a thickness of 2.5 mm prepared in Example 1 was used to prepare a new type of composite electrode, and a new type of lithium metal battery was assembled by designing a non-diaphragm structure. The difference from Example 1 is that the battery structure used to test the coulombic efficiency of the half-cell is: negative electrode casing, lithium sheet-sponge, electrolyte, copper sheet, gasket, shrapnel, and positive electrode casing. see Figure 5 , Figure 5 Schematic diagram of the structure of a lithium metal battery (model: CR2032) designed for the sponge-metal lithium composite electrode without a diaphragm structure for testing the Coulombic efficiency in Example 2 of the present invention.

[0076] The lithium metal sheet and copper sheet used in the experiment were pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com