Method for directly preparing catalyst by using precious metal scraps

A precious metal catalyst and precious metal technology, applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve the problem of high price of high-purity precious metals, achieve high catalytic activity, low material consumption and energy consumption, and realize recycling The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

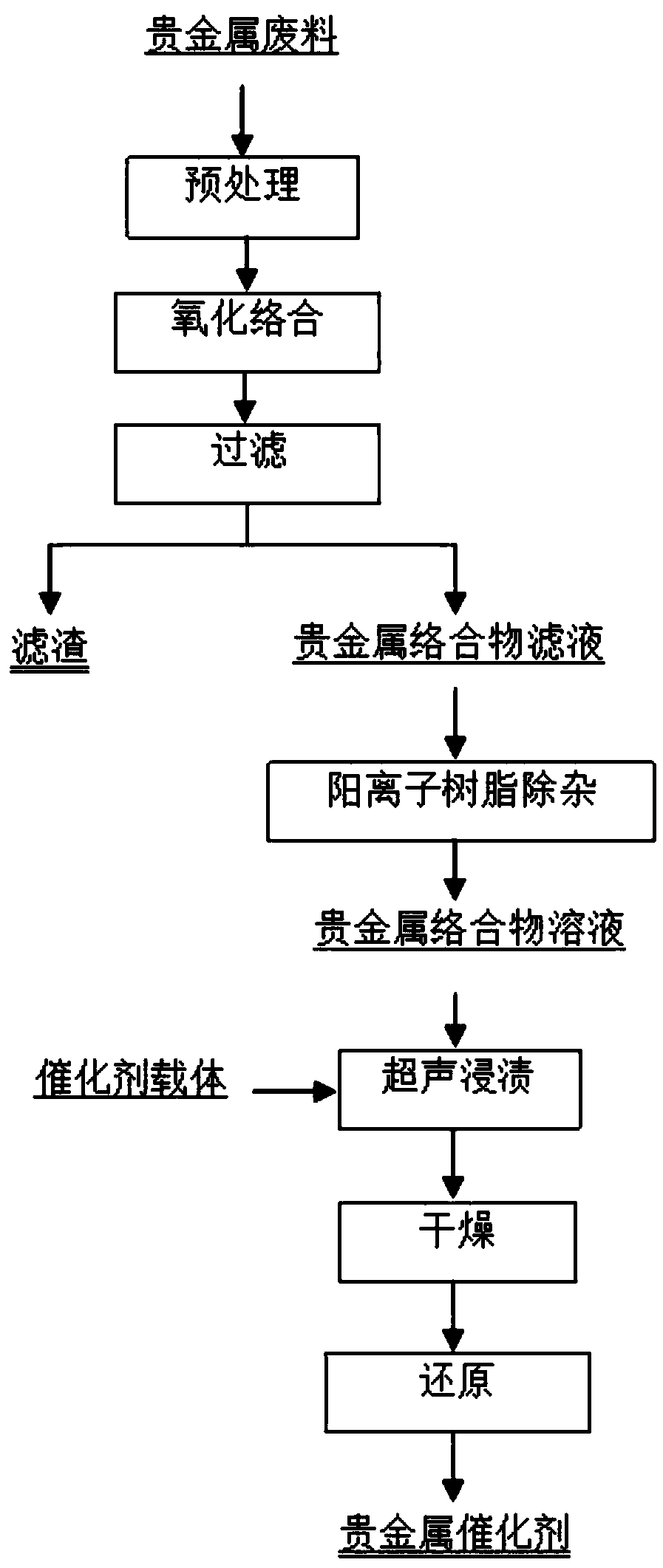

Method used

Image

Examples

Embodiment 1

[0024] The scrapped automobile catalyst is crushed, roasted, reduced to remove carbon deposits and activated. Prepare precious metal oxidation complexing agent: sodium chlorate 20g / L, hydrochloric acid 2.0mol / L, sodium chloride 4.0mol / L. Stir and heat the reduced spent catalyst and oxidizing complexing agent to 90° C., react for 4 hours, and then filter to obtain filter residue and precious metal complex filtrate. Use 732-type cation exchange resin to adsorb metal cations in the noble metal complex filtrate to obtain a noble metal complex solution. The concentration of metal cations in the noble metal complex solution is 92 mg / L, and the noble metal is present in the noble metal complex as an anion complex. in the compound solution. Then put the cordierite carrier in the noble metal complex solution for ultrasonic impregnation for 30 min, then take it out and dry it at 120° C. for 4 h. After drying, the loaded amount of noble metal on the carrier was detected to be 2138g / t, ...

Embodiment 2

[0026] The spent petroleum reforming catalyst is crushed, roasted, reduced to remove carbon deposits and activated. Preparation of noble metal oxidation complexing agent: hydrogen peroxide volume fraction 1.0%, hydrochloric acid 1.0 mol / L, potassium chloride 5.0 mol / L. Stir and heat the reduced spent catalyst and oxidizing complexing agent to 90° C., react for 2 hours, and then filter to obtain filter residue and precious metal complex filtrate. Use D001 type cation exchange resin to adsorb metal cations in the metal complex filtrate, the concentration of metal cations in the noble metal complex solution is 62 mg / L, and the noble metal exists in the metal complex solution as an anion complex. Then γ-Al 2 o 3 After the carrier was placed in the noble metal complex solution for ultrasonic impregnation for 50 min, it was taken out and dried at 110° C. for 6 h. After drying, the loaded amount of noble metal on the carrier was detected to be 3489g / t, meeting the catalyst require...

Embodiment 3

[0028] The waste petroleum hydrogenation catalyst is crushed, roasted, reduced to remove carbon deposits and activated. Prepare precious metal oxidation complexing agent: sodium chlorate 40g / L, sulfuric acid 1.0mol / L, potassium chloride 5.0mol / L. Stir and heat the reduced spent catalyst and oxidizing complexing agent to 90° C., react for 2 hours, and then filter to obtain filter residue and metal complex filtrate. Use D113 type cation exchange resin to adsorb the metal cations in the metal complex filtrate, the metal cation concentration in the noble metal complex solution is 35mg / L, and the noble metal is present in the described noble metal complex solution as an anion complex. Then put the zeolite carrier in the noble metal complex solution for ultrasonic impregnation for 60 min, then take it out and dry it at 100° C. for 8 h. After drying, the loaded amount of precious metal on the carrier was detected to be 4220g / t, meeting the requirements of the catalyst. Finally, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com