A kind of estradiol production process and production device

A production device and estradiol technology are applied in the field of estradiol production process and production device, and can solve the problems of damaged shape and structure variation of intermediate products, reduced estradiol production quality, unstable estradiol crystals, and the like, To achieve the effect of convenient opening of the equipment, improving the convenience of operation, and improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

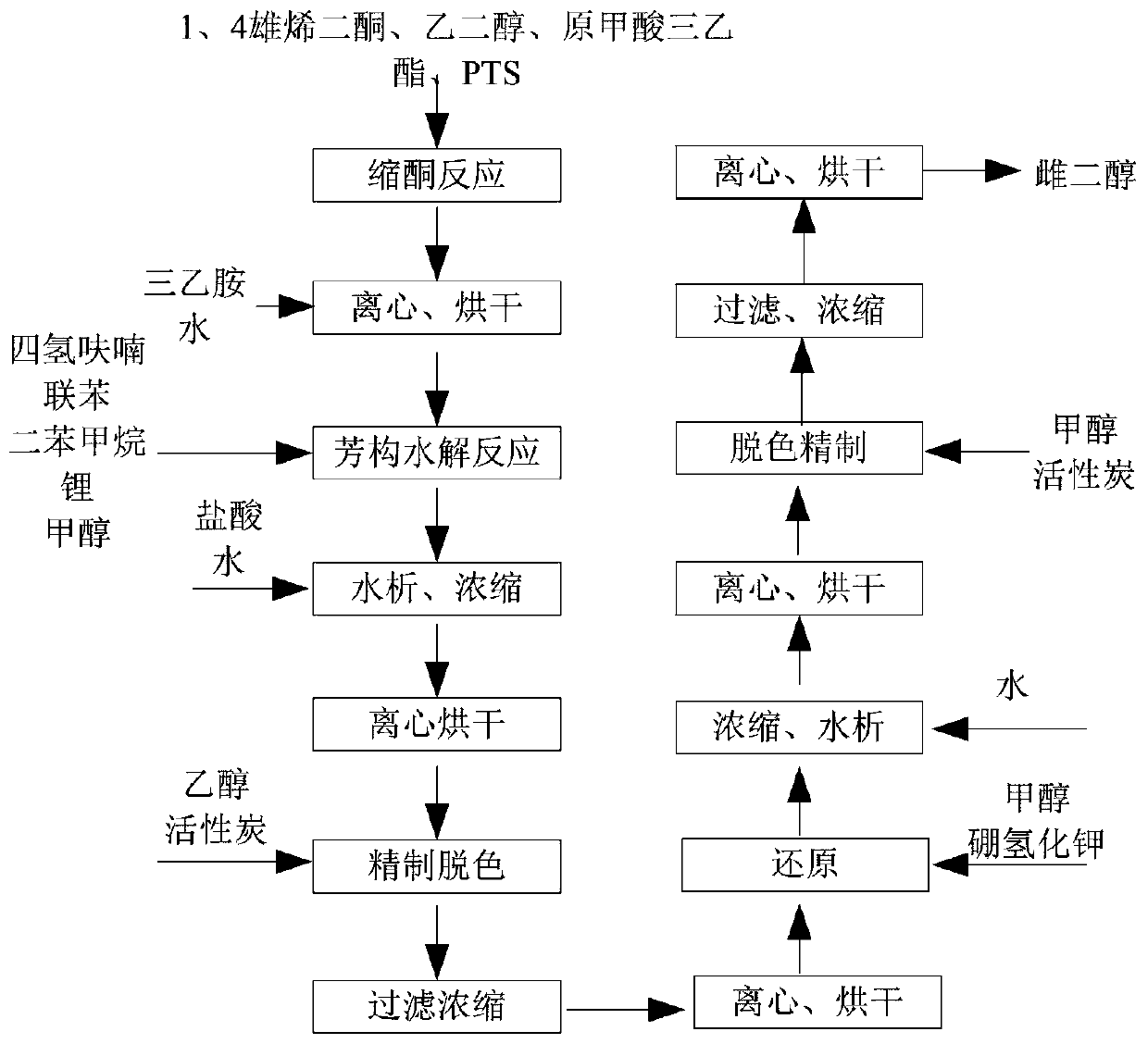

[0079] The process embodiment one of producing estradiol, it comprises following preparation steps:

[0080] Preparation of ketals:

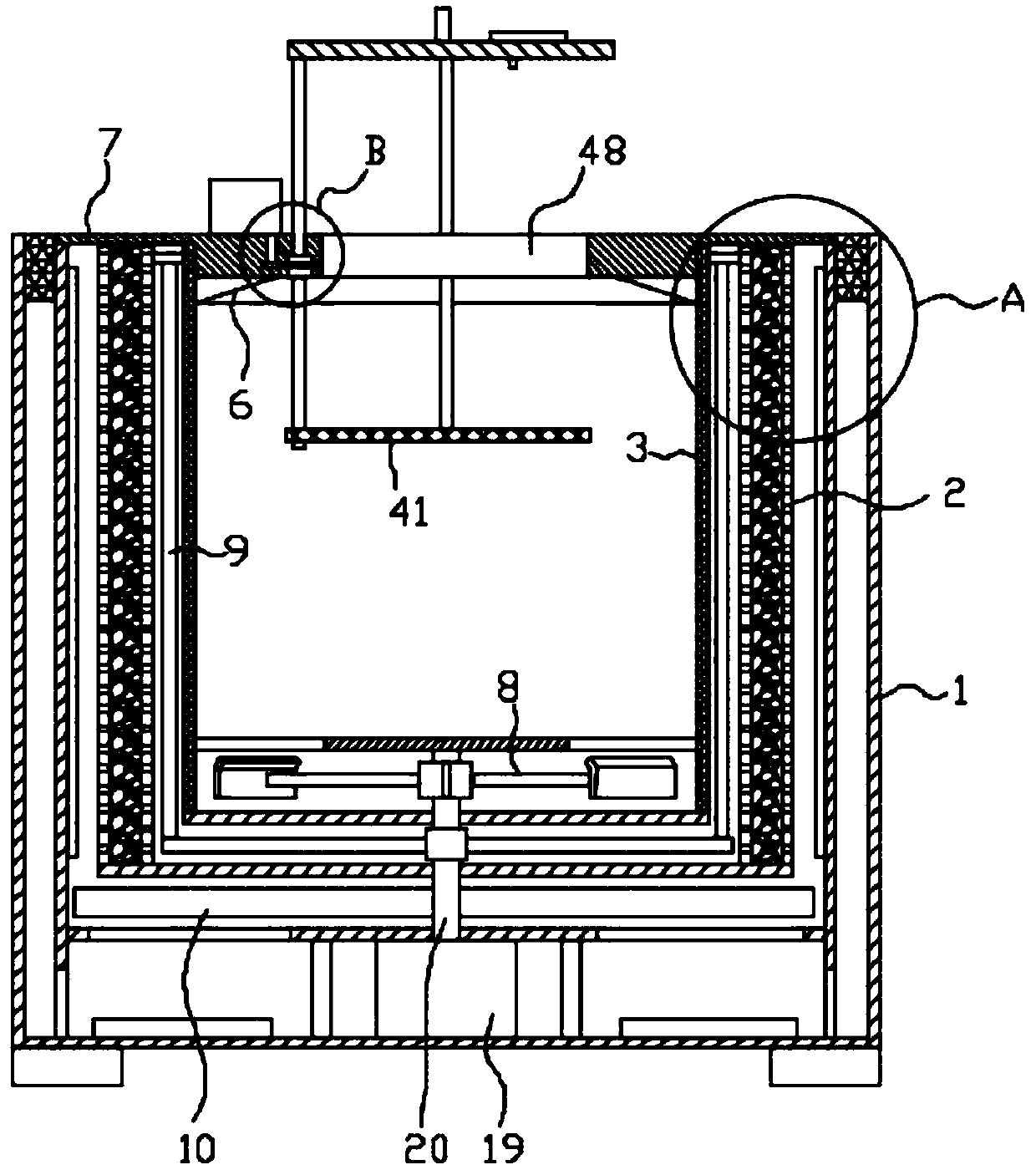

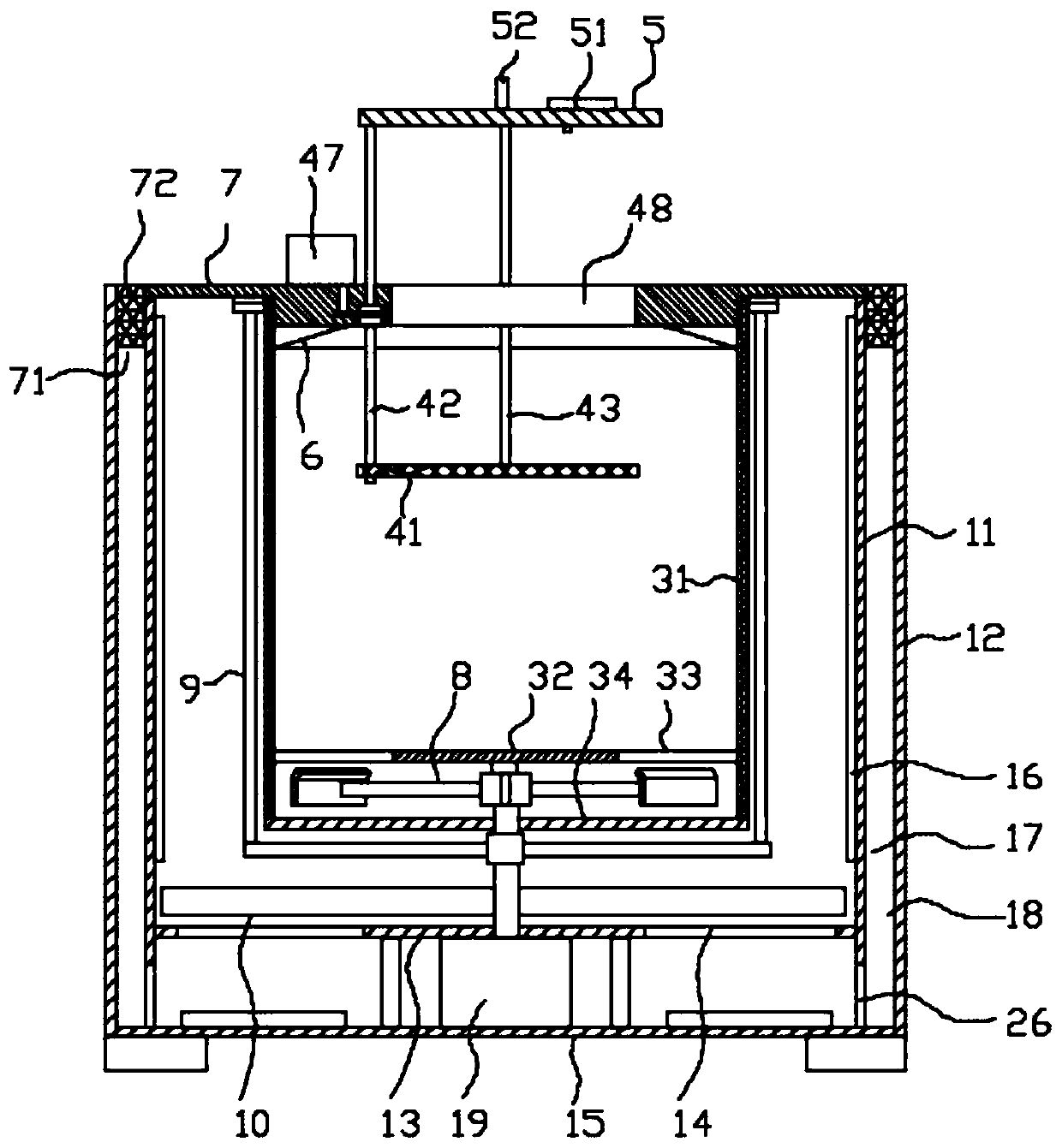

[0081] Pump 160 parts of ethylene glycol and 130 parts of triethyl orthoformate into the reactor, add 2 parts of p-toluenesulfonic acid and 130 parts of 1,4-androstenedione, control the temperature at 15~20°C, and keep it warm for 2 hours , add triethylamine to adjust the pH to 3, add water analysis, centrifuge, wash with water until neutral, put it into the drying equipment, start the infrared heating tube 6, irradiate for 8 minutes, control the motor 19 speed to be 1000r / min, continue Run for 15 minutes to form ketal;

[0082] The reaction formula is:

[0083]

[0084] Aromatization hydrolysis reaction:

[0085] Add 1700 parts of tetrahydrofuran, 55 parts of biphenyl, 70 parts of diphenylmethane, and nitrogen gas into the reaction kettle, adjust the temperature to 35~40°C, add 100% lithium particles, continue to stir at 40~50°C for 30 mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com