Catalyst for preparing propylene through dehydrogenation of propane and preparation method of catalyst

A propane dehydrogenation and catalyst technology, applied in the field of propane dehydrogenation to propylene, can solve the problems of unfavorable reactant and product diffusion, catalyst deactivation, less attention to modulation, etc., and achieves lower crystallization temperature and high propylene selectivity. , the effect of shortening the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

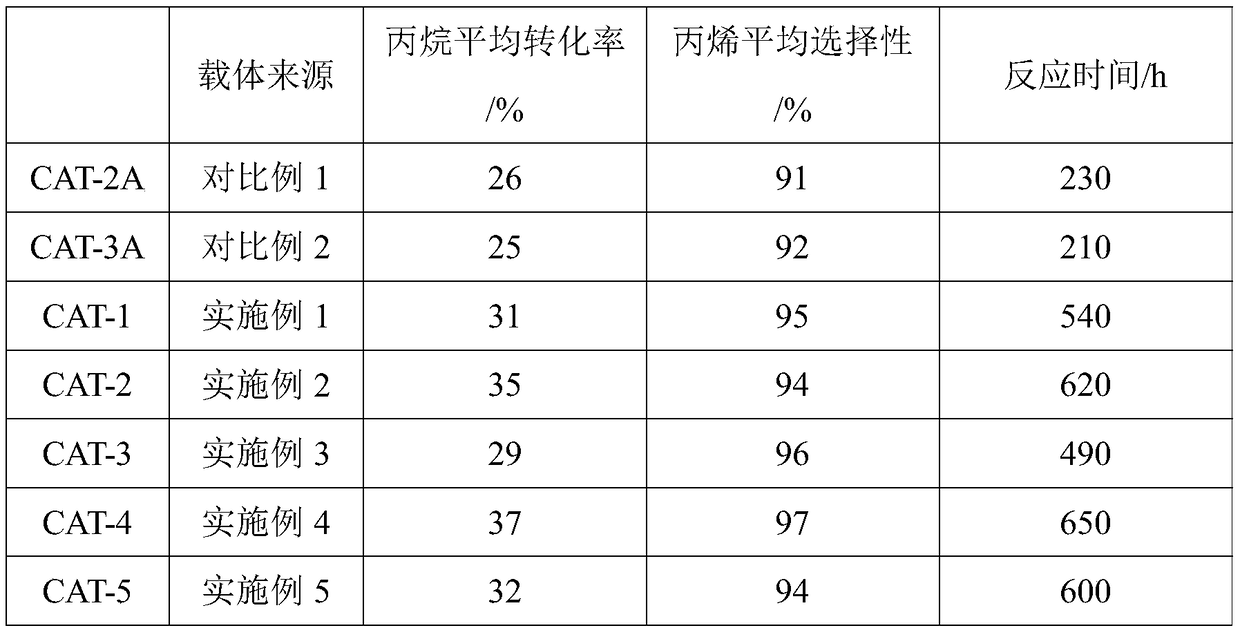

Examples

Embodiment 1

[0038] A method for preparing a catalyst for the dehydrogenation of propane to propylene includes the following steps:

[0039] (Step A1) Mix the silica sol, pseudo-boehmite, tetrapropylammonium hydroxide, and deionized water at a molar ratio of 120:1:10:3000, and stir at 10°C for 8 hours to obtain a gel mixture;

[0040] (Step A2) Put the gel mixture into a stainless steel autoclave lined with polytetrafluoroethylene, put it in an oven after sealing, age at 60°C for 10 hours, and crystallize at 160°C for 24 hours;

[0041] (Step A3) Wash with deionized water, dry at 100°C for 8 hours, and calcinate at 600°C for 2 hours to obtain NaZSM-5 molecular sieve with conventional microporous structure, and then place it in 0.2mol / L sodium hydroxide and 0.5mol / L tetrapropyl group Stir the mixed solution of ammonium hydroxide at 90°C for 1 hour, transfer it into a reactor lined with polytetrafluoroethylene, seal it and put it into a microwave reactor, and react at 100°C for 3 hours;

[0042] (St...

Embodiment 2

[0045] A method for preparing a catalyst for the dehydrogenation of propane to propylene includes the following steps:

[0046] (Step A1) Mix the silica sol, aluminum oxide, tetrapropylammonium hydroxide, and deionized water at a molar ratio of 100:1:10:2000, and stir at 10°C for 8 hours to obtain a gel mixture;

[0047] (Step A2) Put the gel mixture into a stainless steel autoclave lined with polytetrafluoroethylene, put it in an oven after sealing, age at 40°C for 12 hours, and crystallize at 180°C for 24 hours;

[0048] (Step A3) Wash with deionized water, dry at 100°C for 8 hours, and calcinate at 600°C for 2 hours to obtain NaZSM-5 molecular sieve with conventional microporous structure, and then place it in 0.2mol / L sodium carbonate and 0.5mol / L tetrapropyl hydrogen Stir the mixed solution of ammonium oxide at 80°C for 1h, transfer it into a reactor lined with polytetrafluoroethylene, seal it and put it into a microwave reactor, and react at 150°C for 2h;

[0049] (Step A4) Wash...

Embodiment 3

[0052] A method for preparing a catalyst for the dehydrogenation of propane to propylene includes the following steps:

[0053] (Step A1) Mix silica sol, aluminum oxide, triethylamine, and deionized water at a molar ratio of 100:2:10:2500 uniformly, and stir at 20°C for 6 hours to obtain a gel mixture;

[0054] (Step A2) Put the gel mixture into a stainless steel autoclave lined with polytetrafluoroethylene, put it in an oven after sealing, age at 40°C for 12 hours, and crystallize at 180°C for 24 hours;

[0055] (Step A3) Wash with deionized water, dry at 120°C for 8 hours, and calcinate at 550°C for 2 hours to obtain NaZSM-5 molecular sieve with conventional microporous structure, and then place it in 0.5mol / L sodium acetate and 0.5mol / L tetrapropyl Stir the mixed solution of ammonium hydroxide at 80°C for 1 hour, transfer it into a reactor lined with polytetrafluoroethylene, seal it and put it into a microwave reactor, and react at 150°C for 2 hours;

[0056] (Step A4) Wash with de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com