Biomass solid clean fuel as well as preparation method and application thereof

A technology for clean fuels and biomass raw materials, applied in solid fuels, biofuels, waste fuels, etc., can solve the problems of no solid clean fuels, insignificant economic benefits, increased processing costs, etc., and achieves simple and feasible preparation. Low content and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

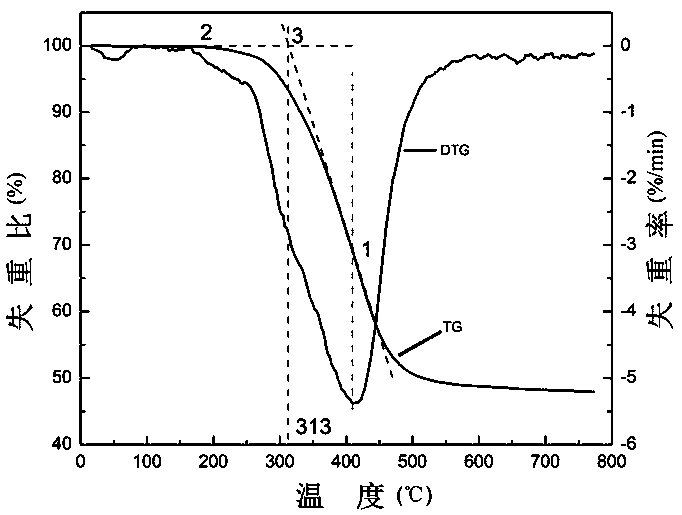

Embodiment 1

[0038] A kind of biomass solid clean fuel, which is made of sludge (residual dewatered sludge of urban sewage treatment plant) and biomass waste (sawdust) as raw materials, after pretreatment, acid-base treatment and hydrothermal carbonization After treatment, it is made by hot pressing. The atomic percentage of carbon in the prepared biomass solid clean fuel is 41.70%, and the atomic percentage of nitrogen is 2.09%. The high calorific value of the biomass solid clean fuel can reach 17.70MJ / kg .

[0039] A preparation method of the biomass solid clean fuel in the above-mentioned present embodiment, comprising the following steps:

[0040] (1) Pretreatment of sludge and biomass waste:

[0041] (1.1) Wash and dry the sawdust, specifically at 40°C for 24 hours; crush the dried sawdust through a 1mm sieve.

[0042] (1.2) Mix 10g of sawdust sieved in step (1.1) with 100g of sludge with a water content of 90% (residual dewatered sludge from urban sewage treatment plants), and stir...

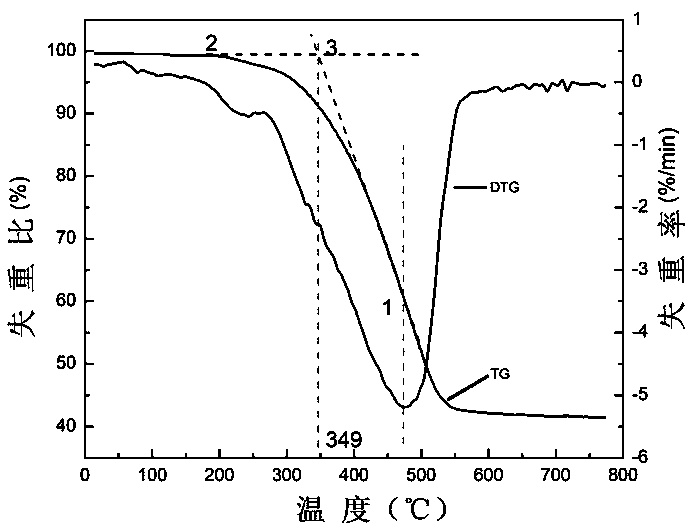

Embodiment 2

[0054] A kind of biomass solid clean fuel, the biomass solid clean fuel is made of sludge (residual dewatered sludge of urban sewage treatment plant) and biomass waste (corncob) as raw materials, after pretreatment, acid-base treatment and hydrothermal It is produced by hot pressing after carbonization treatment, and the atomic percentage of carbon in the prepared biomass solid clean fuel is 50.13%; the higher calorific value of the biomass solid clean fuel is 22.22MJ / kg.

[0055] A preparation method of the above-mentioned biomass solid clean fuel in this embodiment, compared with the preparation method in Embodiment 1, the difference is that: in step (1), the biomass waste is corn cobs; in step (2) , the pH value was adjusted to 7; in step (3), the temperature in the reactor was 260°C.

[0056] The biomass solid clean fuel prepared in Example 2 of the present invention is coded as SS-CC.

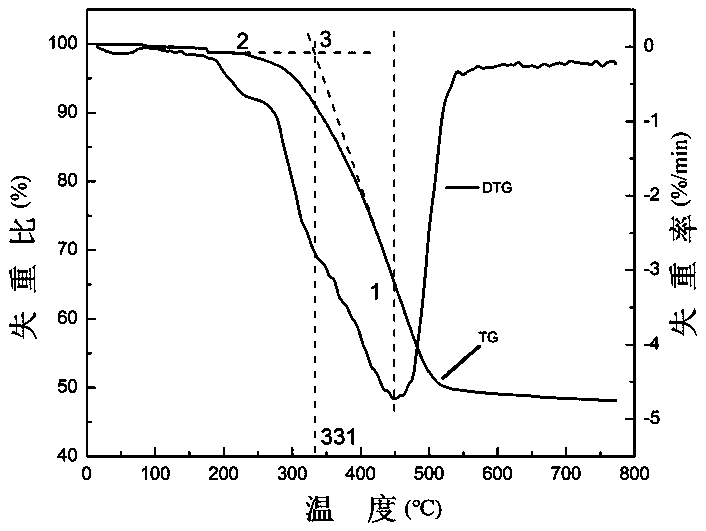

Embodiment 3

[0058] A kind of biomass solid clean fuel, the biomass solid clean fuel is made of sludge (residual dewatered sludge of urban sewage treatment plant) and biomass waste (corn straw) as raw materials, after pretreatment, acid-base treatment and hydrothermal It is produced by hot pressing after carbonization treatment, and the carbon content in the prepared biomass solid clean fuel is 37.45%; the higher heat value of the biomass solid clean fuel is 15.92MJ / kg.

[0059] A preparation method of biomass solid clean fuel in the above-mentioned embodiment, compared with the preparation method in embodiment 1, the difference is that: in step (1), the biomass waste is corn stalks; in step (2) , the pH value was adjusted to 7; in step (3), the temperature in the reactor was 260°C.

[0060] The biomass solid clean fuel prepared in Example 3 of the present invention is coded as SS-CS.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com