Preparation method of pressure-resistant anti-high temperature oil-water separation filter paper

A technology of oil-water separation and high temperature resistance, applied in separation methods, filter paper, filtration and separation, etc., can solve the problems of easy softening of fibers, insufficient pressure resistance of oil-water separation filter paper, etc., to reduce brittleness, excellent oil-water separation effect, and improve burst resistance. The effect of strength and tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

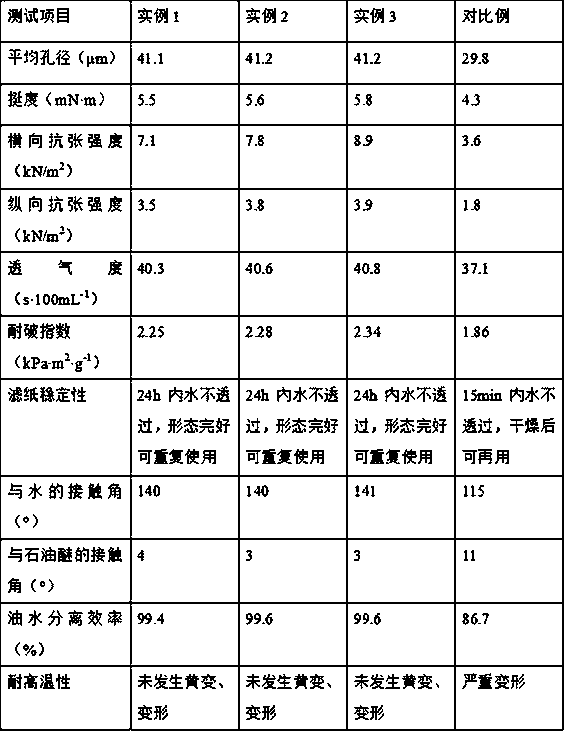

Examples

example 1

[0026] Add distilled water to the 3mm alkali-free ultrafine glass fiber to make a glass fiber suspension with a solid mass content of 20%, then add 98% concentrated sulfuric acid, adjust the pH to 3.5, stir and disperse to obtain a suspension. The bleached softwood pulp with a mass content of 20% is put into a hydraulic pulper to disintegrate, and then stirred by a beating machine to control the beating degree at 40°SR to obtain a beating liquid. The beating liquid and the glass fiber suspension are in volume ratio 3:1 mix, add anionic polyacrylamide, continue to stir to obtain a pulp suspension, which is ready for use, in which the mass of anionic polyacrylamide accounts for 0.6% of the pulp suspension; in parts by weight, disperse 2 parts of nano titanium dioxide in 20 parts of distilled water After stirring and heating in a water bath to 60°C, add ferroferric oxide colloid with a solid mass content of 30%. After the dropwise addition is completed, stir at 350r / min for 1.0h, a...

example 2

[0028] Add distilled water to the 4mm alkali-free ultrafine glass fiber to make a glass fiber suspension with a solid mass content of 20%, then add 98% concentrated sulfuric acid, adjust the pH to 3.7, stir and disperse to obtain a suspension. The bleached softwood pulp with a mass content of 20% is put into a hydraulic pulper to disintegrate, and then stirred by a beating machine to control the beating degree at 43°SR to obtain a beating liquid. The beating liquid and the glass fiber suspension are in volume ratio 3:1 mix, add anionic polyacrylamide, continue to stir to obtain a pulp suspension, which is ready for use, where the mass of anionic polyacrylamide accounts for 0.7% of the pulp suspension; in parts by weight, disperse 2 parts of nano titanium dioxide in 23 parts of distilled water After stirring and heating in a water bath to 63°C, add ferroferric oxide colloid with a solid mass content of 30%. After the addition is complete, stir at 380r / min for 1.3h, and centrifuge...

example 3

[0030] Add distilled water to a 5mm alkali-free ultrafine glass fiber to make a glass fiber suspension with a solid mass content of 20%, then add 98% concentrated sulfuric acid, adjust the pH to 4.0, stir and disperse to obtain a suspension. The bleached softwood pulp with a mass content of 20% is put into a hydraulic pulper to disintegrate, and then stirred by a beating machine to control the beating degree at 45°SR to obtain a beating liquid. The beating liquid and the glass fiber suspension are in volume ratio 3:1 mix, add anionic polyacrylamide, continue to stir to obtain a pulp suspension, which is ready for use, in which the mass of anionic polyacrylamide accounts for 0.8% of the pulp suspension; in parts by weight, disperse 3 parts of nano titanium dioxide in 25 parts of distilled water After stirring and heating in a water bath to 65°C, add ferroferric oxide colloid with a solid mass content of 30%. After the dropwise addition is complete, stir at 400r / min for 1.5h, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com