Production process of winding layer of logging signal cable

A technology for cable winding and well logging signals, which is applied in the direction of communication cables, cable/conductor manufacturing, cables, etc., can solve the problems of short service life of well logging cables and easy damage of well logging cables, and achieve strong bending resistance, Ease of demolding and increased strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

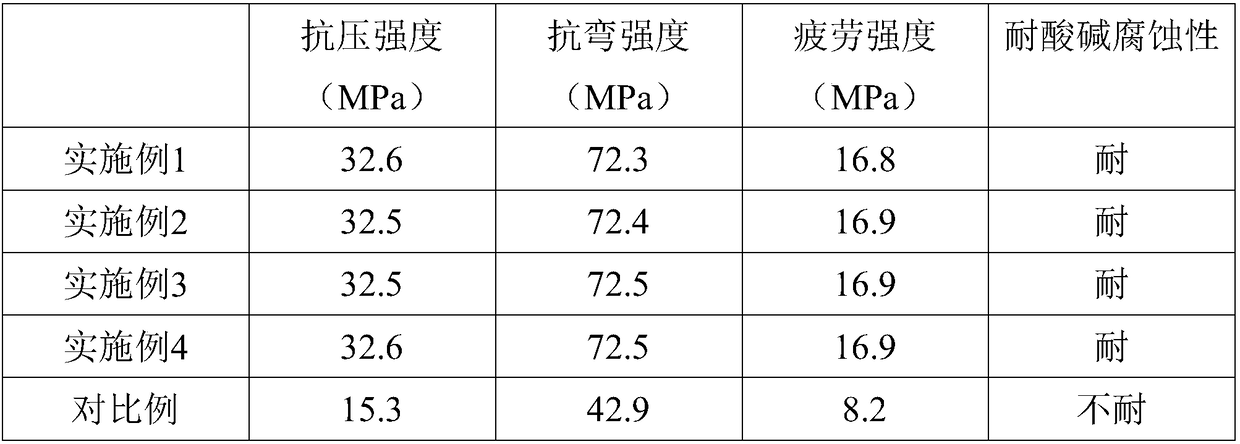

Examples

Embodiment 1

[0025] A production process for a well logging signal cable winding layer, comprising the following steps:

[0026] (1) Mix 100 parts of nano-titanium dioxide-modified polyvinyl chloride, 50 parts of polystyrene, 30 parts of corundum-modified polycarbonate and 20 parts of isoprene rubber, and put them in a high-speed mixer and stir for 40 minutes at a speed of 600 r / min. After stirring, add a urea solution with a mass concentration of 5% that is 20 times the weight of the mixture into the mixture, put the mixed solution into a closed environment filled with a mixture of hydrogen and nitrogen, and let it stand at 110°C for 30 minutes, wherein the pressure of the mixture is 2Mpa, the volume ratio of hydrogen to nitrogen is 2:3, filter after standing, wash the precipitate with deionized water, put it in a vacuum drying oven to dry;

[0027] (2) Dissolve the dried mixture in the above steps in a calcium chloride solution that is 30 times the weight of the mixture and have a mass c...

Embodiment 2

[0031] A production process for a well logging signal cable winding layer, comprising the following steps:

[0032] (1) Mix 150 parts of nano-titanium dioxide-modified polyvinyl chloride, 80 parts of polystyrene, 60 parts of corundum-modified polycarbonate and 40 parts of isoprene rubber, and put them into a high-speed mixer and stir for 60 minutes at a speed of 800 r / min. After stirring, add urea solution with a mass concentration of 26 times the weight of the mixture to the mixture, and put the mixed solution into a closed environment full of hydrogen and nitrogen gas mixture, and let it stand at 140°C for 40min, wherein the pressure of the mixture gas 3Mpa, the volume ratio of hydrogen to nitrogen is 2:3, filter after standing, wash the precipitate with deionized water, put it in a vacuum drying oven to dry;

[0033] (2) Dissolve the dried mixture in the above steps in a calcium chloride solution that is 50 times the weight of the mixture and have a mass concentration of 13...

Embodiment 3

[0041] A production process for a well logging signal cable winding layer, comprising the following steps:

[0042] (1) Mix 120 parts of nano-titanium dioxide modified polyvinyl chloride, 60 parts of polystyrene, 40 parts of corundum modified polycarbonate and 30 parts of isoprene rubber, and put them into a high-speed mixer and stir for 50 minutes at a speed of 700r / min After stirring, add a urea solution with a mass concentration of 6% that is 22 times the weight of the mixture into the mixture, put the mixed solution into a closed environment filled with a mixture of hydrogen and nitrogen, and let it stand at 120°C for 35 minutes, wherein the pressure of the mixture is 2Mpa, the volume ratio of hydrogen to nitrogen is 2:3, filter after standing, wash the precipitate with deionized water, put it in a vacuum drying oven to dry;

[0043] (2) Dissolve the dried mixture in the above steps in a calcium chloride solution that is 40 times the weight of the mixture and have a mass c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com