Small-caliber bionic blood vessel with three-layer structure and manufacturing method thereof

A bionic blood vessel, three-layer structure technology, applied in the field of bionic blood vessels, can solve the problems of inability to meet the needs of small-diameter blood vessels, easy to form thrombus, vascular intimal hyperplasia, etc., achieve high strength, promote cell reproduction, and improve the effect of burst pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

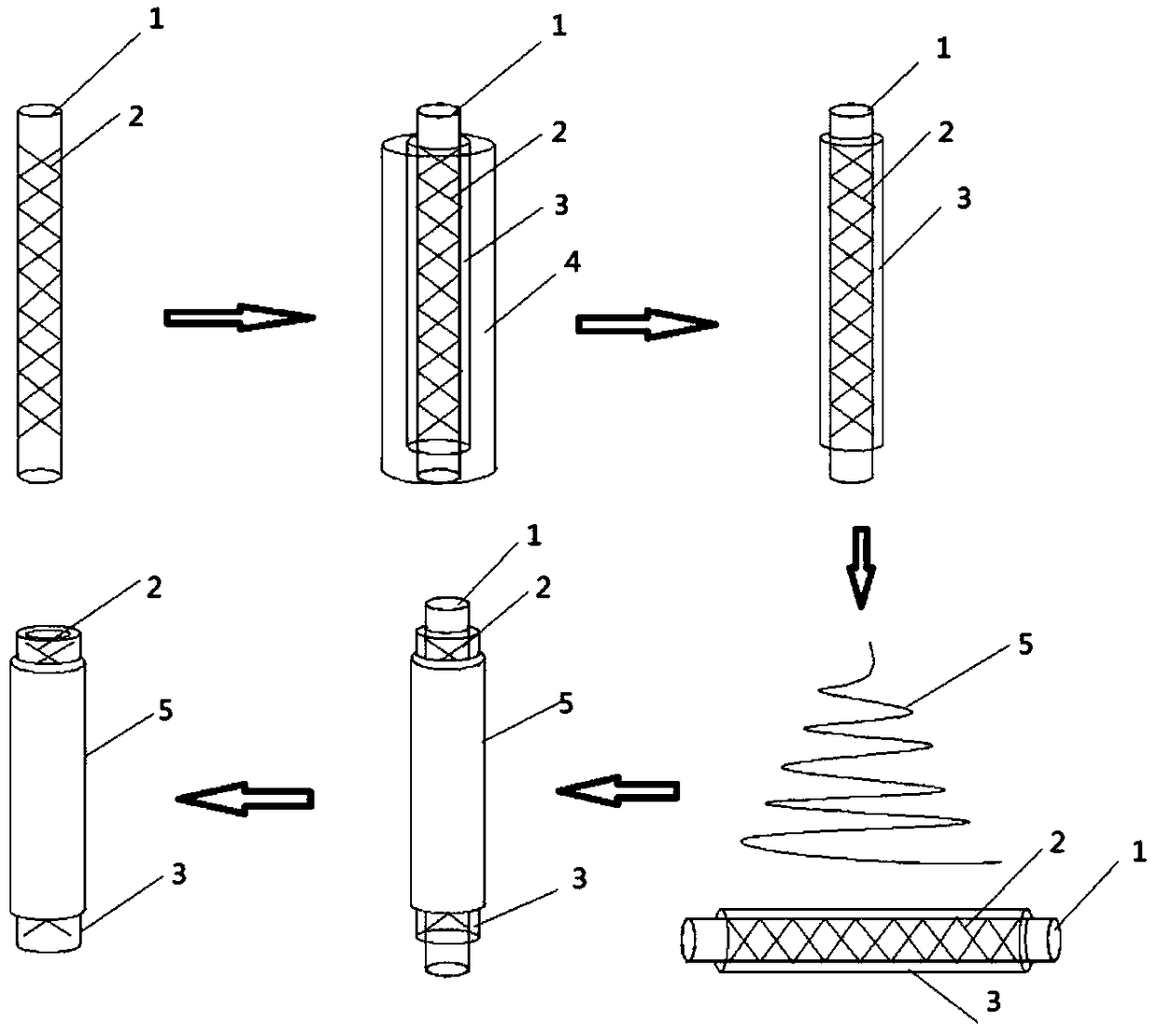

[0042] According to the three-layer structure small-caliber bionic blood vessel, a preparation method is provided, the steps include:

[0043] S1. Use silk fiber to weave a net-like inner layer structure outside the round tube;

[0044] S2. In step S1, a hollow cylindrical mold is used to pour the polyacrylamide hydrogel precursor solution to cross-link the polyacrylamide hydrogel precursor solution to obtain a silk fiber / polyacrylamide hydrogel tube double-layer structure;

[0045] S3. Prepare a polyurethane nanofiber outer layer structure outside the double-layered silk fiber / polyacrylamide hydrogel tube obtained in step S2 to obtain a three-layer structure small-diameter bionic blood vessel.

[0046] Further, in step S1, the inner layer meshed silk fiber has a ring diameter of 2-5 mm and a thickness of 100-200 μm; the polyacrylamide hydrogel tube in step S2 has a diameter of 400-600 μm; and the polyurethane nanometer in step S3 The fiber diameter is 50-150nm, and the thickness is 5...

Embodiment 1

[0057] This embodiment provides a method for preparing a small-caliber bionic blood vessel with a three-layer structure.

[0058] S1. Use 50μm diameter silk fiber to weave a 100μm thick net-like inner layer structure outside a 2mm round tube;

[0059] S2. Use acrylamide and phosphate buffer to make a 2mol / L solution, add 0.06% of acrylamide mass of methylene bisacrylamide and 0.17% of acrylamide mass of ammonium persulfate to the solution, add propylene after dissolving 0.25% of the amide mass of tetramethylethylenediamine is fully stirred to obtain a polyacrylamide hydrogel precursor.

[0060] S3. Use a hollow cylindrical mold to cast the polyacrylamide hydrogel precursor prepared in step S2 on the silk woven in step S1 and irradiate it with ultraviolet for 40 minutes to obtain a silk fiber / polyacrylamide hydrogel tube double-layer structure;

[0061] S4. The polyurethane is dissolved in dimethylformamide to prepare a polyurethane solution with a concentration of 10wt.%;

[0062] S5. ...

Embodiment 2

[0064] This embodiment provides a method for preparing a small-caliber bionic blood vessel with a three-layer structure.

[0065] S1. Use 50μm diameter silk fiber to weave a 100μm thick net-like inner layer structure outside a 2mm round tube;

[0066] S2. Use acrylamide and phosphate buffer to make a 2mol / L solution, add 0.06% of acrylamide mass of methylene bisacrylamide and 0.17% of acrylamide mass of ammonium persulfate to the solution, add propylene after dissolving 0.25% of the amide mass of tetramethylethylenediamine is fully stirred to obtain a polyacrylamide hydrogel precursor.

[0067] S3. Use a hollow cylindrical mold to cast the polyacrylamide hydrogel precursor prepared in step S2 on the silk woven in step S1, and heat it at 50°C for 40 minutes to obtain a silk fiber / polyacrylamide hydrogel tube double-layer structure ;

[0068] S4. The polyurethane is dissolved in dimethylformamide to prepare a polyurethane solution with a concentration of 10wt.%;

[0069] S5. Using the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com