Composite photocatalyst, preparation method and application thereof

A catalyst and composite light technology, applied in the field of photocatalysis, can solve the problem of low photocatalytic efficiency, and achieve the effects of good dispersion, good fluidity and good catalytic degradation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method of above-mentioned composite photocatalyst is:

[0036] Step 1, degreasing, roughening, activating, and silane coupling treatment are performed on the hollow glass microspheres in sequence, so that the surface of the hollow glass microspheres is free of impurities and rich in hydroxyl groups;

[0037] The degreasing process is as follows: disperse the hollow glass microspheres in the degreasing liquid, stir at 60-80°C for 20-30min, filter and wash with water. Wherein, the degreasing liquid is prepared by dissolving sodium hydroxide, sodium carbonate and sodium silicate in deionized water according to the volume-mass concentration ratio of 8:2:1. Preferably, the mass volume concentrations of sodium hydroxide, sodium carbonate and sodium silicate in the oil removal solution are 40g / L, 10g / L and 5g / L respectively. The amount of hollow glass microspheres added is 10g to 20g to 1L of degreasing liquid.

[0038] The coarsening process is as follows: soa...

Embodiment 1

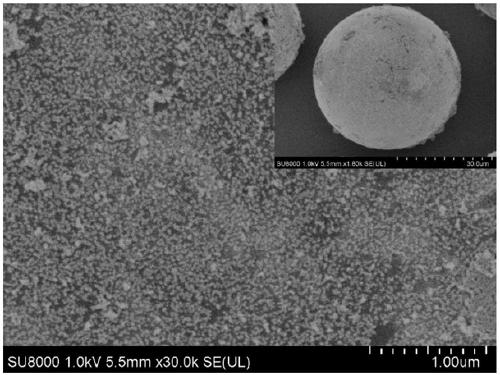

[0048] First, pretreat the hollow glass microspheres: degreasing: prepare a mixture of 1L 40g / L sodium hydroxide, 10g / L sodium carbonate and 5g / L sodium silicate and heat it to 95°C, and take the nominal diameter distribution as φ15 10g of -75μm GS60 hollow glass microspheres were added to the mixture, and the hollow microspheres were fully dispersed by mechanical stirring. After 45 minutes, the upper layer of floating microspheres was taken for suction filtration and washed with deionized water, and then dried at 60°C; The hollow glass microspheres after the above treatment were placed in 5% ammonium fluoride solution, heated in a water bath at 60°C and magnetically stirred, washed with acetone, absolute ethanol, and deionized water respectively until neutral after 2 hours, and made after suction filtration. Drying treatment; Activation: configure hydrogen peroxide acidic solution (wt(H 2 o 2 ) = 5%, wt (HCl) = 6%), put the roughened and dried hollow glass microspheres in th...

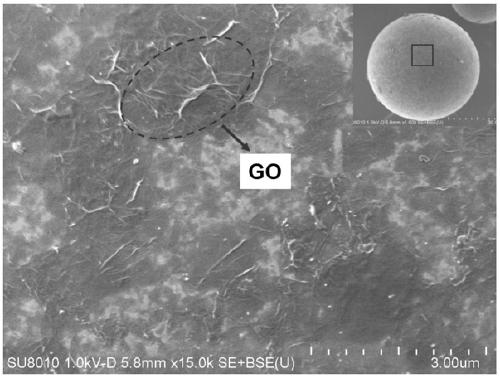

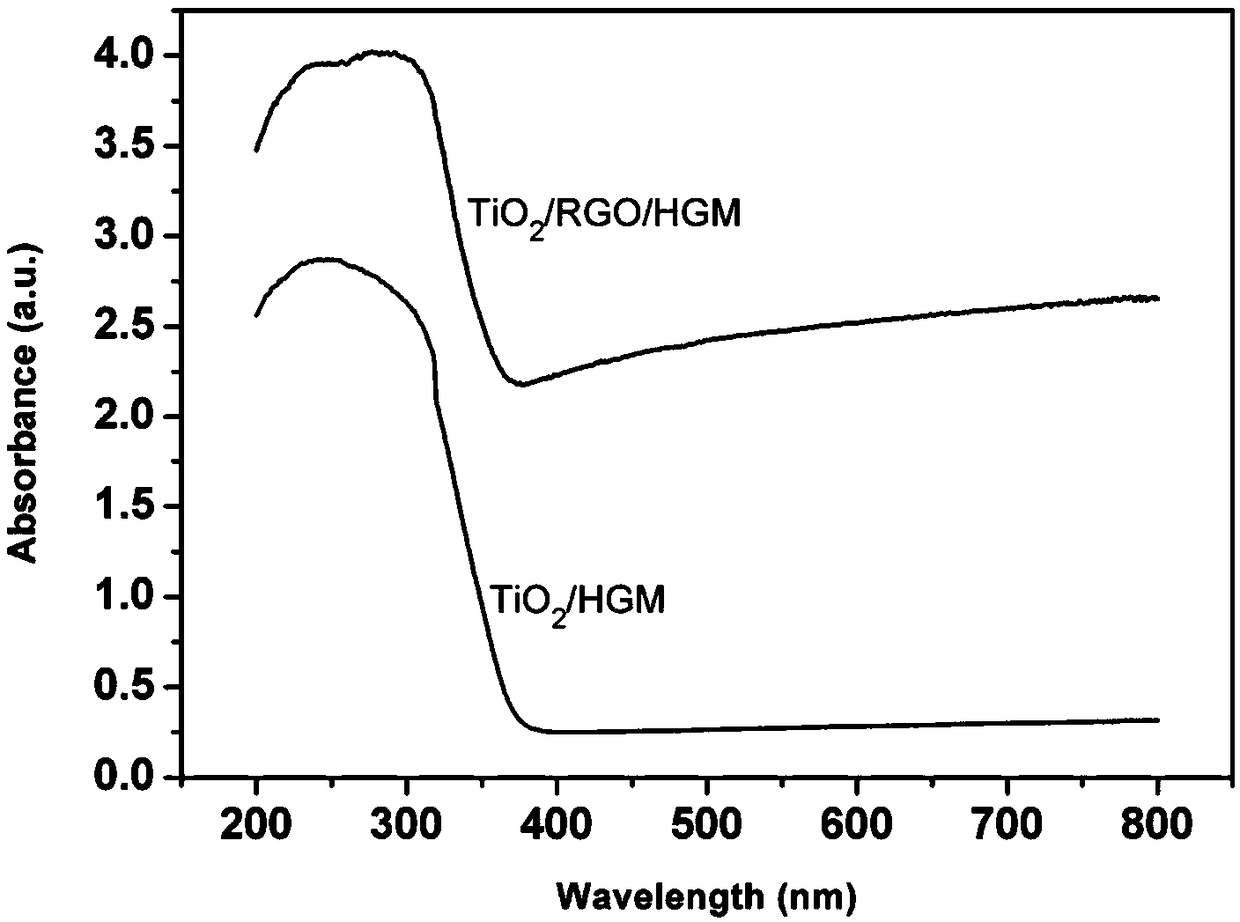

Embodiment 2

[0059] The difference between this embodiment and embodiment 1 is: according to the mass ratio of the amount of graphene oxide added to the pretreated hollow glass microspheres is 0.1%. The TiO that present embodiment obtains 2 The degradation efficiency of the / graphene / hollow glass microsphere composite photocatalyst is 88%-90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com