Method for preparing tungsten-doped porous vanadium dioxide powder and thin film by virtue of cotton sacrifice template method

A vanadium dioxide, sacrificial template technology, applied in vanadium oxide, nanotechnology for materials and surface science, nanotechnology, etc. Vanadium oxide film phase transition temperature visible light transmittance, film phase transition temperature does not decrease and other problems, to ensure visible light transmittance, improve visible light transmittance, and achieve excellent main performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

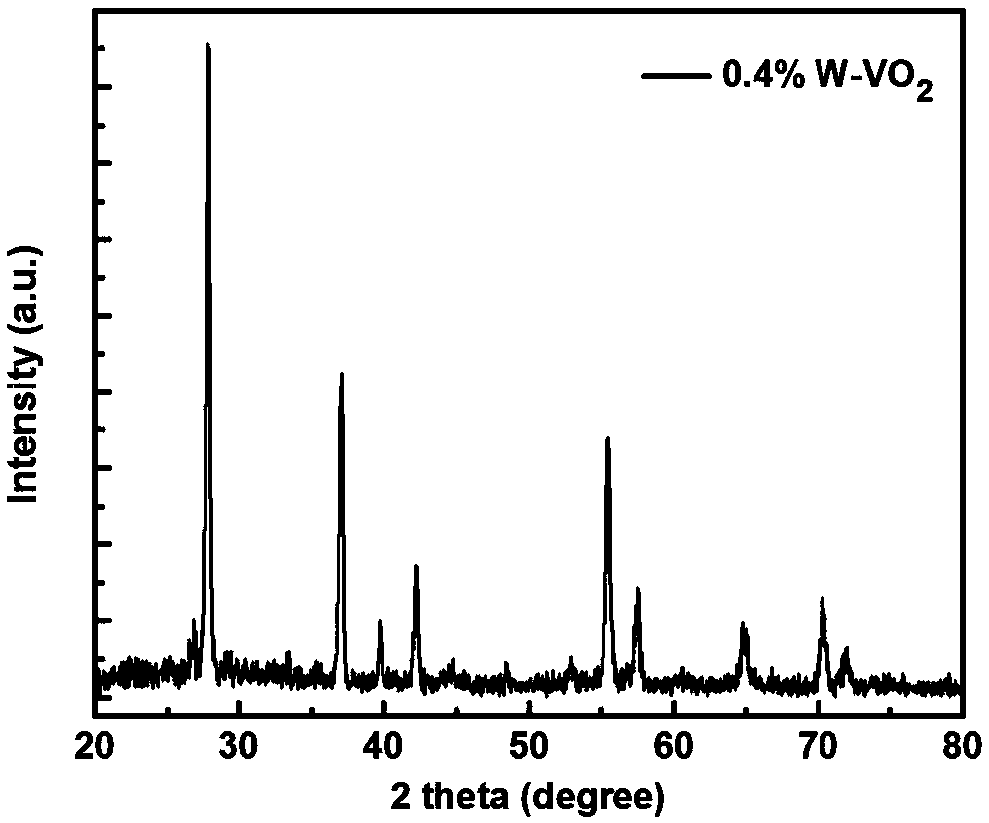

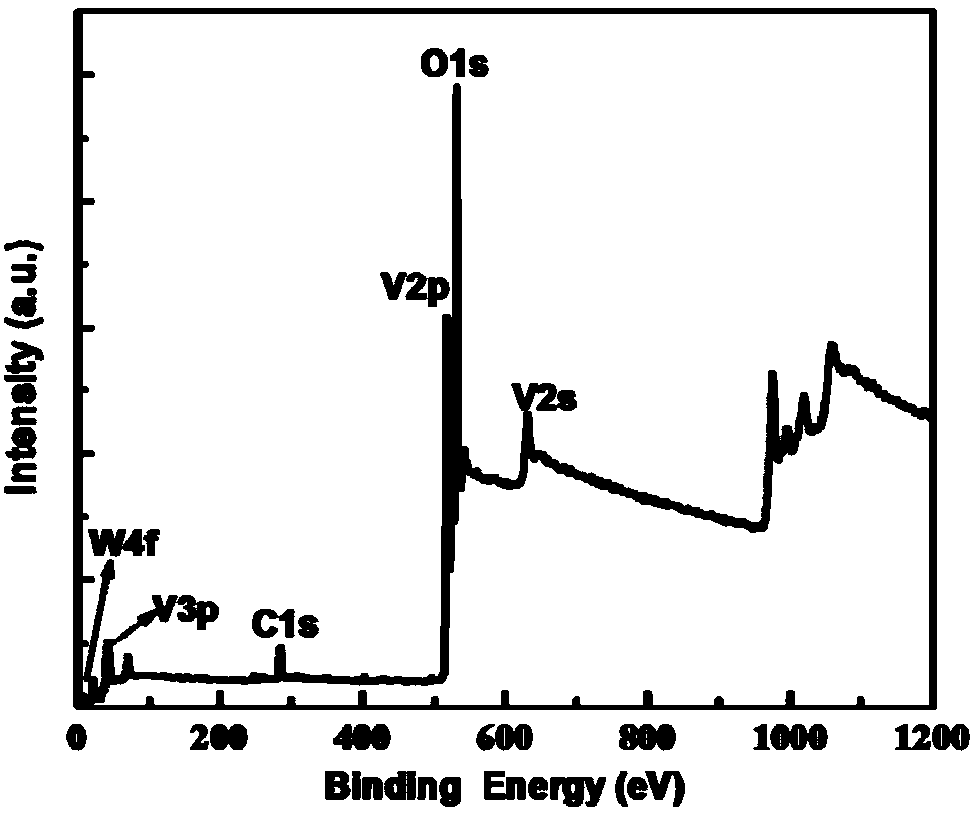

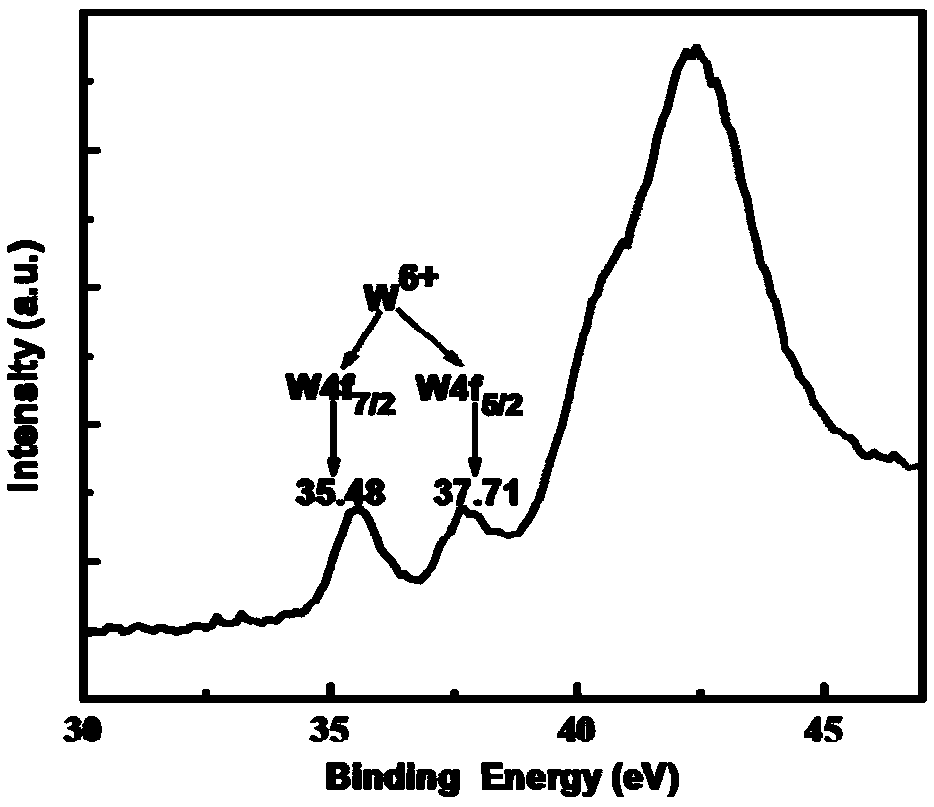

Embodiment 1

[0036] 1) Weigh 0.4g (0.0022mol) vanadium pentoxide, 0.0046g (7.326*10 -7 mol) ammonium tungstate and 0.832g (0.0066mol) oxalic acid dihydrate in a 100mL beaker, then add 30mL deionized water, place the beaker in a water bath at 80°C and stir for 20min to obtain a blue precursor solution;

[0037] 2) Take out the beaker and keep stirring, add 30mL of ethylene glycol after cooling to room temperature, and continue stirring for 10min to obtain a homogeneous solution;

[0038] 3) Slowly add ammonia water dropwise to the above homogeneous solution to adjust the pH of the solution to 7;

[0039] 4) Add the mixed solution and 0.4g of absorbent cotton into a 100mL reactor, put the reactor into an oven for hydrothermal reaction at 180°C for 24 hours, and take it out after cooling down to room temperature naturally;

[0040] 5) Take out the absorbent cotton in the reaction kettle, first wash it twice with deionized water, then wash it once with ethanol, and then put it in an oven at 8...

Embodiment 2

[0058] 1) Weigh 0.4g (0.0022mol) vanadium pentoxide, 0.0023g (7.326*10 -7 mol) ammonium tungstate and 0.832g (0.0066mol) oxalic acid dihydrate in a 100mL beaker, then add 30mL deionized water, place the beaker in a water bath at 80°C and stir for 25min to obtain a blue precursor solution;

[0059] 2) Take out the beaker and keep stirring, add 30mL of ethylene glycol after cooling to room temperature, and continue stirring for 10min to obtain a homogeneous solution;

[0060] 3) Slowly add ammonia water dropwise to the above homogeneous solution to adjust the pH of the solution to 8;

[0061] 4) Add the mixed solution and 0.35g of absorbent cotton together into a 100mL reaction kettle, put the reaction kettle into an oven, conduct a hydrothermal reaction at 180°C for 20h, and take it out after naturally cooling to room temperature;

[0062] 5) Take out the absorbent cotton in the reaction kettle, first wash it twice with deionized water, then wash it once with ethanol, and then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com