Integrated photovoltaic encapsulation material with high reflectivity and application thereof

A packaging material, high reflectivity technology, applied in photovoltaic power generation, semiconductor devices, electrical components, etc., can solve the problems of high cross-linking degree of packaging materials, cell splits, and high surface hardness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

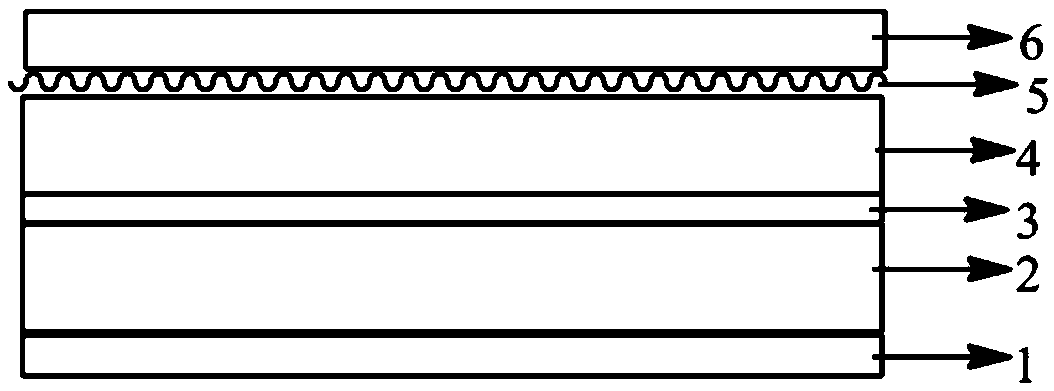

[0072] Layer thickness:

[0073]

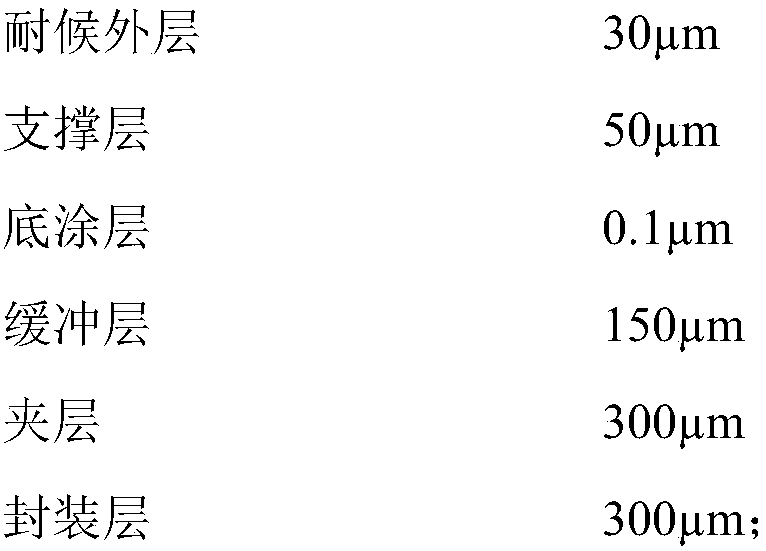

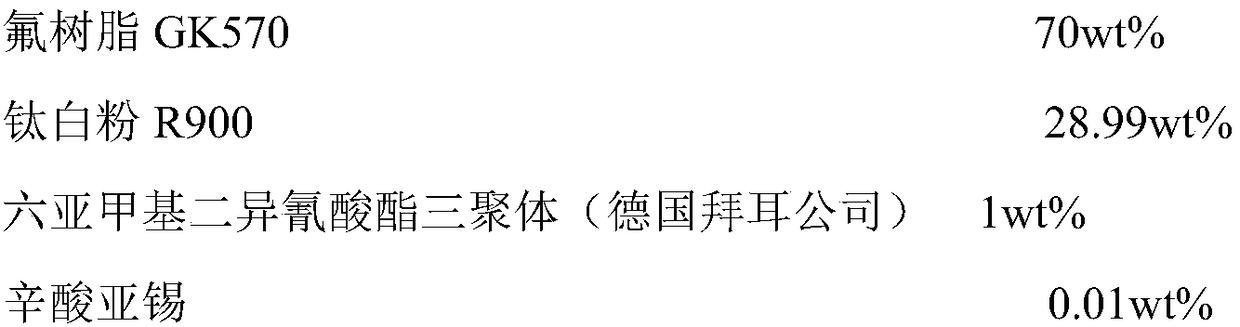

[0074] Weather Resistant Outer Formula:

[0075]

[0076] Support Layer Recipe:

[0077]

[0078] Primer formulation:

[0079]

[0080] Buffer layer recipe:

[0081]

[0082]

[0083] Encapsulation layer formula:

[0084]

[0085] in,

[0086] The interlayer is a glass fiber grid membrane, and the grid area is 50 μm 2 of round shape.

[0087] The modified resin in the primer layer is prepared through the following steps:

[0088] 1) N-(β-aminoethyl)-γ-aminopropylmethyldimethoxysilane with a mass fraction of 0.05%, 5% carbodiimide UN150 (Euen Chemical), 40% acrylic acid Add resin HK77010 (Haoren International) and 54.95% polyester resin GK110 (Toyobo) into an anhydrous reactor and mix evenly;

[0089] 2) Raise the temperature of the reactor to 100°C and stir for 180 minutes to obtain the solute; 3) After cooling down to 80°C naturally, add ethyl acetate solvent equal to the mass of the solute to dilute while stirri...

Embodiment 2

[0092] Layer thickness:

[0093]

[0094]

[0095] Weather Resistant Outer Formula:

[0096]

[0097] Support Layer Recipe:

[0098]

[0099] Primer formulation:

[0100]

[0101] Buffer layer recipe:

[0102]

[0103] Encapsulation layer formula:

[0104]

[0105]

[0106] in,

[0107] The interlayer is a glass fiber grid membrane, and the grid area is 10 μm 2 rectangle.

[0108] The modified resin in the primer layer is prepared through the following steps:

[0109] 1) The mass fraction is 0.1% of isopropyl tris (dioctyl pyrophosphate acyloxy) titanate, 4% of carbodiimide AS4 (Rhine Chemical), 10.9% of acrylic resin HU57024 (Haoren International) ) and 85% polyester resin 220# (Toyobo), add in anhydrous reactor and mix evenly;

[0110] 2) Raise the temperature of the reactor to 150°C and stir for 120 minutes to obtain the solute;

[0111] 3) After natural cooling to 80°C, slowly stir while adding methyl ethyl ketone solvent equal to the mass ...

Embodiment 3

[0114] Layer thickness:

[0115]

[0116] Weather Resistant Outer Formula:

[0117]

[0118]

[0119] Support Layer Recipe:

[0120]

[0121] Primer formulation:

[0122]

[0123] Buffer layer recipe:

[0124]

[0125] Encapsulation layer formula:

[0126]

[0127] in,

[0128] The interlayer is a polyamide grid membrane, and the grid area is 30mm 2 of hexagons.

[0129] The modified resin in the primer layer is prepared through the following steps:

[0130] 1) N-(β-aminoethyl)-γ-aminopropylmethyldimethoxysilane, 5% carbodiimide AS1 (Rhine Chemical), 38% acrylic resin with a mass fraction of 5% Add LR7664 (Mitsubishi Rayon) and 52% polyester resin GK680 (Toyobo) into an anhydrous reactor and mix evenly;

[0131] 2) Raise the temperature of the reactor to 260°C and stir for 10 minutes to obtain the solute; 3) After cooling down to 80°C naturally, add butyl acetate solvent equal to the mass of the solute to dilute while stirring slowly and set aside ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com