Amorphous Ga2O3 solar-blind ultraviolet detector and preparation method and application thereof

An ultraviolet detector and detector technology, applied in semiconductor devices, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of optical band gap change, poor structural repeatability, high cost, and achieve improved response speed, excellent Stable, stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

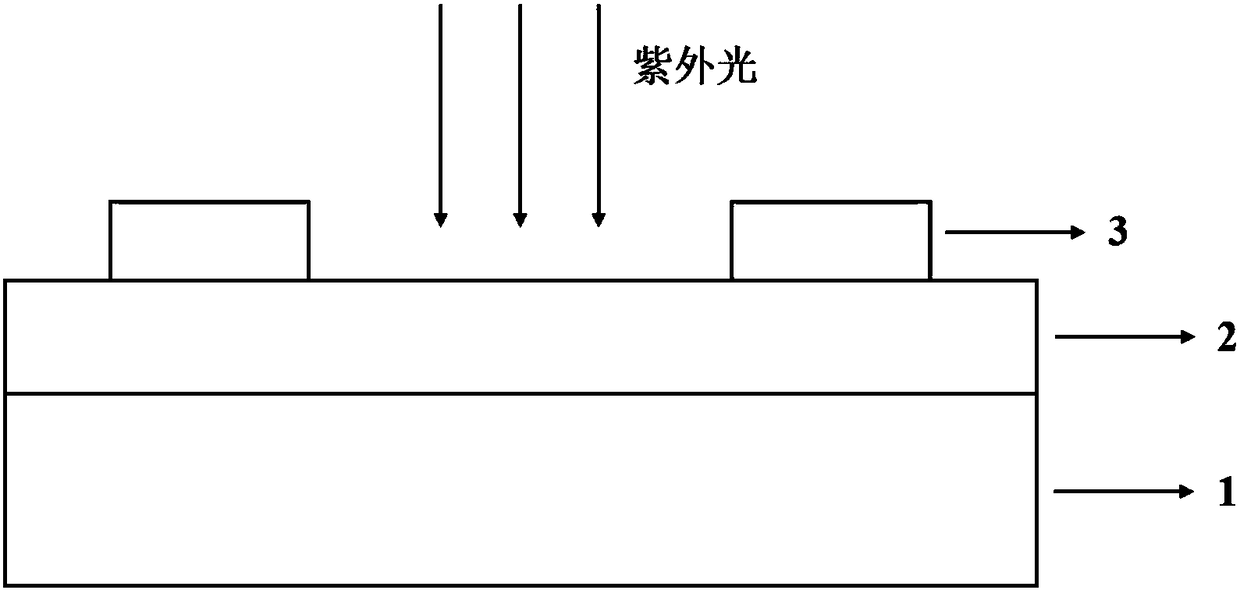

[0039] This embodiment is used to illustrate the amorphous Ga of the present invention 2 o 3 Fabrication process of solar-blind UV detector. figure 1 The amorphous Ga of this embodiment 2 o 3 Schematic diagram of the structure of a solar-blind ultraviolet detector. Such as figure 1 As shown, the detector includes a deep ultraviolet ultrapure quartz substrate 1 , a gallium oxide thin film active layer 2 and an indium tin oxide interdigitated electrode 3 from bottom to top.

[0040] The specific preparation method of the sun-blind ultraviolet detector of the present embodiment is as follows:

[0041] 1) A 25mm×25mm×0.5mm far-ultraviolet ultrapure quartz substrate was ultrasonically cleaned, dried with dry high-purity nitrogen, and placed on a sample holder of the same size. After fixing the substrate, put it into the magnetron sputtering chamber equipped with a gallium oxide ceramic target (purity: 99.999%), raise the sample stage to the highest point (the distance between...

Embodiment 2

[0050] Prepare amorphous Ga of the present invention according to the method substantially identical with embodiment 1 2 o 3 The solar-blind ultraviolet detector, the difference is that in step 2), after the back vacuum is lowered to less than 5E-5Pa, 0.112 sccm of high-purity oxygen is introduced, and the vacuum in the cavity reaches 1.0E-3Pa. After stabilization, wait for 10 minutes, and when the oxygen flow rate and the vacuum in the chamber are stable, 10 sccm of high-purity argon gas is introduced, and the vacuum in the chamber reaches 1.6E-1Pa, and the Ga 2 o 3 film.

Embodiment 3

[0052] Prepare amorphous Ga of the present invention according to the method substantially identical with embodiment 1 2 o 3 The sun-blind ultraviolet detector, the difference is that in step 2) after the back vacuum is lowered to less than 5E-5Pa, 0.126 sccm of high-purity oxygen is introduced, and the vacuum in the cavity reaches 1.2E-3Pa. After stabilization, wait for 10 minutes. If the oxygen flow rate and the vacuum in the chamber are stable, then 10 sccm of high-purity argon gas is introduced, and the vacuum in the chamber reaches 1.6E-1Pa. Start sputtering Ga 2 o 3 film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com