Manganese dioxide-manganese tetroxide composite material, preparation method and application thereof

A technology of manganese tetroxide composite material and manganese dioxide, which is used in nanotechnology for materials and surface science, electrode manufacturing, secondary batteries, etc., can solve the problems of low rate performance and cycle stability less than carbon materials. , to achieve the effect of slow capacity decay, rich hydroxyl and sufficient mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A preparation method of manganese dioxide-trimanganese tetraoxide composite material, comprising the following steps:

[0024] 1) After mixing 10ml 0.05mol / L potassium permanganate solution and 10ml 0.5mol / L manganese sulfate solution, the molar ratio of potassium permanganate and manganese sulfate is 1:10, add 2ml glycerol under ultrasonic conditions, Ultrasonic disperse for 30min and mix well to obtain a mixed solution;

[0025] 2) Add 0.365gCTAB and 0.5ml of 25wt% ammonia water to the mixed system prepared in step 1), mix well, seal, and heat to 155°C for 12h reaction; after the reaction, wash, dry, and cool to room temperature, that is have to.

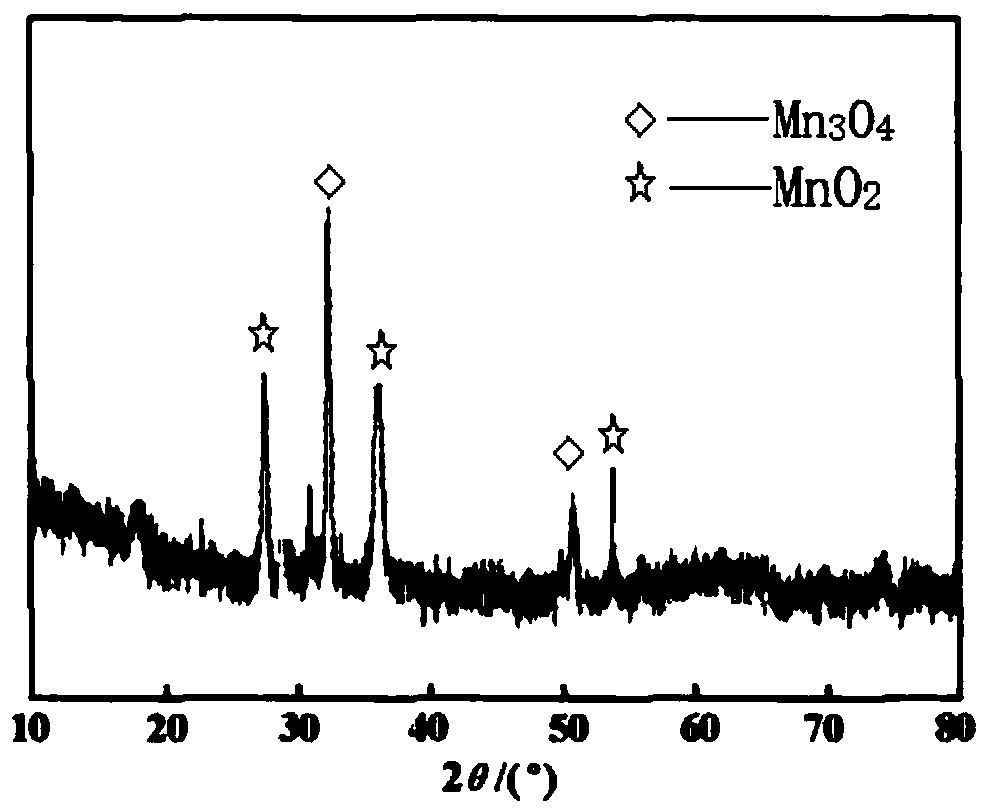

[0026] A manganese dioxide-trimanganese tetraoxide composite material is prepared by the above method. The composite material has a uniform size and is a nano-sized nano-rod structure. The diameter of the nano-rod is 5-80nm and the length is 50-1000nm.

Embodiment 2

[0028] The application of a manganese dioxide-trimanganese tetraoxide composite material as a lithium ion battery negative electrode material, the specific application method is as follows:

[0029] Add carbon black, the manganese dioxide-trimanganese tetraoxide composite material prepared in Example 1, and the binder into deionized water, and stir to obtain the negative electrode slurry. The mass ratio of manganese dioxide-trimanganese tetraoxide composite material, carbon black, binder and deionized water is 100:2:4:113. The obtained negative electrode slurry is evenly coated on the metal current collector, and the coating thickness is controlled to be 50-60 μm, then dried, pressed into tablets, and punched to obtain a negative electrode sheet that can be used as a lithium ion battery negative electrode. Assemble the battery with the positive plate of the ionic lithium battery, conduct a test, carry out charge and discharge cycles at a current density of 100mAh / g, test the c...

Embodiment 3

[0031] A preparation method of manganese dioxide-trimanganese tetraoxide composite material, comprising the following steps:

[0032] 1) After mixing 10ml 0.05mol / L potassium permanganate solution and 10ml 0.5mol / L manganese sulfate solution, the molar ratio of potassium permanganate and manganese sulfate is 1:10, add 2ml ethylene glycol under ultrasonic conditions, Ultrasonic disperse for 30min and mix well to obtain a mixed solution;

[0033] 2) Add 0.365gCTAB and 0.5ml of 25wt% ammonia water to the mixed system prepared in step 1), mix well, seal, and heat to 165°C for 10h reaction; after the reaction, wash, dry, and cool to room temperature, that is have to.

[0034] A manganese dioxide-trimanganese tetraoxide composite material is prepared by the above method. The composite material has a uniform size and is a nano-sized nanorod structure. The diameter of the nanorod is 5-80nm and the length is 50-1000nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com