Method for preparing nitrogen-oxygen codoped biomass porous carbon material through two-step pre-carbonation

A porous carbon material and pre-carbonization technology, applied in the fields of carbon compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of single material composition, easy loss of heteroatoms, loss of heteroatoms, etc. Enhanced chemical adsorption capacity, high repetition rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

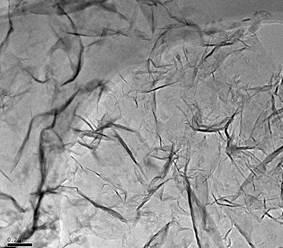

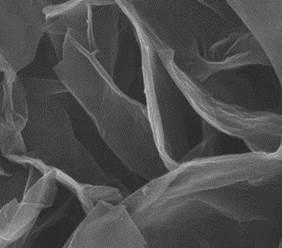

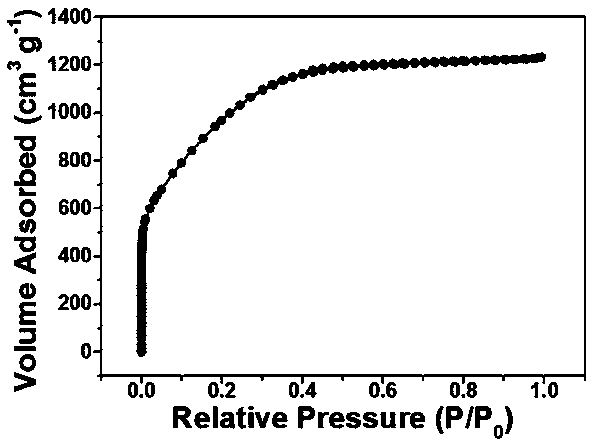

Image

Examples

Embodiment 1

[0016] Wash and dry the corn granules, put them in a rigid airtight container to heat up and pressurize, then open the container to communicate with the outside world, so that the corn granules are puffed; put the puffed corn granules into a 50 ml reaction kettle, and heat to 160 ℃ and kept for 24 hours. After cooling down, the product was taken out from the reactor and transferred to a tube furnace. Nitrogen was continuously passed as a protective gas. The temperature was raised to 450°C at a heating rate of 2°C / min and reacted for 2 hours to obtain pre-carbonized Product: Grind the pre-carbonized product and potassium hydroxide in a mortar at a mass ratio of 1:3 to make it evenly mixed, then transfer the mixture to a tube furnace, and heat up to 700°C under nitrogen for 2.5 hours , the obtained product was washed to neutrality and dried to prepare a nitrogen-oxygen co-doped biomass porous carbon material.

Embodiment 2

[0018] Wash and dry the rice granules, put them in a rigid airtight container to heat up and pressurize, and then open the container to communicate with the outside world to make the rice granules puff; put the puffed rice granules into a 50ml reaction kettle and heat to 240 ℃ and keep it warm for 12 hours. After cooling down, the product is taken out from the reaction kettle and transferred to a tube furnace. The nitrogen gas is continuously passed as a protective gas, and the temperature is raised to 450°C at a heating rate of 2°C / min and reacted for 5 hours to obtain the pre-carbonized Product: Grind the pre-carbonized product and potassium hydroxide in a mortar at a mass ratio of 1:3 to make it evenly mixed, then transfer the mixture to a tube furnace, and heat up to 800°C under nitrogen for 1.5 hours , the obtained product was washed to neutrality and dried to prepare a nitrogen-oxygen co-doped biomass porous carbon material.

Embodiment 3

[0020] Wash and dry the soybean granules, put them into a rigid airtight container to heat up and pressurize, then open the container to communicate with the outside world to make the soybean granules puff; put the puffed soybean granules into a 50ml reaction kettle and heat to 200 ℃ and kept for 24 hours. After cooling down, the product was taken out from the reaction kettle and transferred to a tube furnace. The nitrogen gas was continuously passed as a protective gas, and the temperature was raised to 450°C at a heating rate of 2°C / min for 3 hours to obtain the pre-carbonized Product: Grind the pre-carbonized product and potassium hydroxide in a mortar with a mass ratio of 1:3 to make it evenly mixed, then transfer the mixture to a tube furnace, and heat up to 900°C under nitrogen for 2 hours , the obtained product was washed to neutrality and dried to prepare a nitrogen-oxygen co-doped biomass porous carbon material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com