A method and system for preparing cyclohexyl acetate and separating cyclohexane and acetic acid

A technology of cyclohexyl acetate and cyclohexane, which is applied in the direction of carboxylate preparation, chemical instruments and methods, distillation purification/separation, etc., can solve the problems of unsuitability for large-scale industrial production, high cost, and low output, and achieve Reduce investment cost and operating cost, reduce separation energy consumption, and shorten the effect of separation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

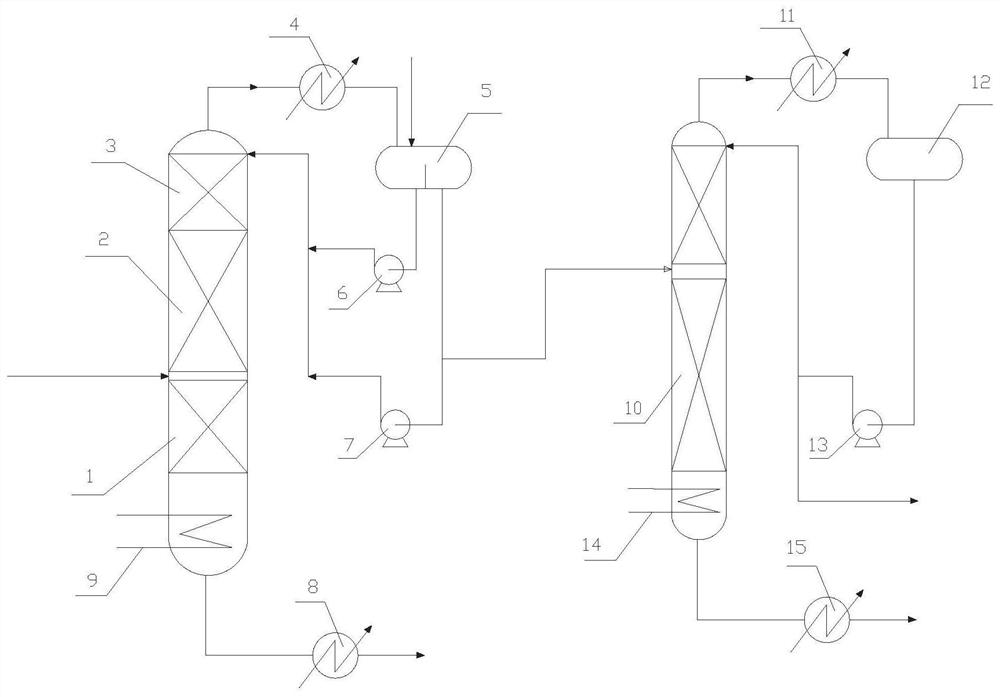

Embodiment 1

[0093] step one

[0094] Under normal pressure, benzene is partially hydrogenated to obtain a mass fraction of 75% cyclohexene, 25% cyclohexane, and the mixture of 10ppm benzene is added from the feed port of the reactive distillation tower with acetic acid of 2kg / h and 3kg / h. The mol ratio of cyclohexene is 2.7, establish tower still liquid level 60%, tower still heats up, control reaction section (2) reaction temperature 78~90 ℃, and set up tower top oil-water phase tank (5) oil phase liquid level 60% -80%, start the oil phase reflux pump (7) at the top of the tower, and control the oil phase reflux ratio to 10;

[0095] step two

[0096] Add water in the water phase area of the oil-water phase tank (5), establish the water phase liquid level of 30-50%, start the water phase reflux pump (6) on the top of the tower, and adjust the water phase reflux flow rate to about 0.55kg / h (the amount of reflux water is the tower 10% of the sum of the top oil phase reflux and the mass...

Embodiment 2

[0100] step one

[0101] Under normal pressure, benzene is partially hydrogenated to obtain a mass fraction of 35% cyclohexene, 15% cyclohexane, and a mixture of 50% benzene is added from the feed port of the reactive distillation tower at 2 kg / h and 0.56 kg / h of acetic acid. The molar ratio of acetic acid to cyclohexene is 1.1, and the liquid level of the tower kettle is 60%, the temperature of the tower kettle is raised, the reaction temperature of the reaction section (2) is controlled at 78-100° C., and the oil-water phase tank (5) oil phase liquid at the top of the tower is established. Bit 60-80%, the oil phase reflux ratio is controlled to 0;

[0102] step two

[0103] Add water in the water phase area of the oil-water phase tank (5), set up the water phase liquid level of 30-50%, start the water phase reflux pump (6) on the top of the tower, and adjust the water phase reflux flow rate to about 0.14kg / h (the amount of reflux water is the tower 11% of the sum of the ...

Embodiment 3

[0107] step one

[0108] Under normal pressure, benzene is partially hydrogenated to obtain a mass fraction of 1.025% cyclohexene, 98.775% cyclohexane, and a mixture of 0.2% benzene. Add 2 kg / h and 3 kg / h of acetic acid from the feed port of the reactive distillation tower, and the acetic acid The molar ratio with cyclohexene is 200, and the liquid level of the tower kettle is established at 60%, the temperature of the tower kettle is raised, the reaction temperature of the reaction section (2) is controlled at 78-90°C, and the oil-water phase tank (5) at the top of the tower is established. 60-80%, the oil phase reflux ratio is controlled at 2;

[0109] step two

[0110] Add water in the water phase area of the oil-water phase tank (5), set up the water phase liquid level of 30-50%, start the water phase reflux pump (6) on the top of the tower, and adjust the water phase reflux flow rate to about 0.56kg / h (the amount of reflux water is the tower 9.0% of the sum of the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com