Waterborne alkyd resin and preparation method thereof

A technology of water-based alkyd resin and polyol, which is applied in coatings, polyester coatings, etc., can solve the problems of poor coating applicability and poor water resistance, and achieve improved initial water resistance, higher glass transition temperature, and better water release sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

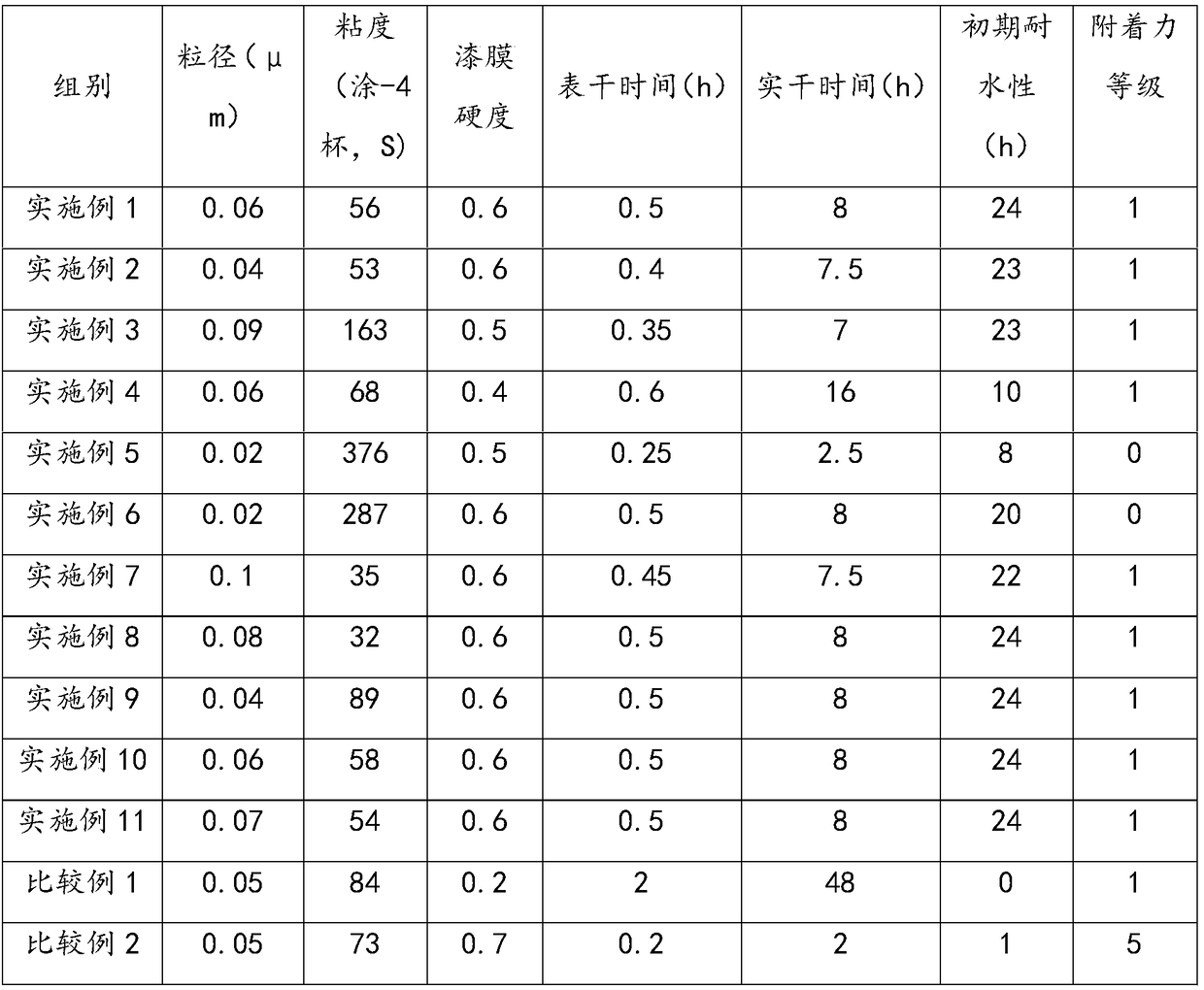

Examples

preparation example Construction

[0041] The present invention also provides a kind of preparation method of described waterborne alkyd resin, comprises the steps:

[0042] (a) Mix linseed oil, maleic anhydride, isophthalic acid and polyols, keep warm at 220-230°C until the acid value is reduced to ≤10mg KOH / g, cool down to 140-150°C, add trimellitic anhydride, Heat preservation at 130-140°C to reduce the acid value to ≤60mg KOH / g to obtain material a;

[0043] (b) cooling material a to 110-120°C, adding acrylic monomers, and reacting at 120°C for 0.5-2 hours to obtain material b;

[0044] (c) The initiator is dissolved in part of the co-solvent, added to material b, kept warm for 0.5-2h, cooled to 95-105°C, added the rest of the co-solvent, cooled to 70-85°C, added neutralizer, and adjusted the pH value For 6-7, add water and stir evenly.

[0045] In a preferred embodiment of the present invention, in the step (c), the initiator is dissolved in 1 / 4-1 / 3 of the amount of co-solvent. More preferably, the init...

Embodiment 1

[0049] The water-based alkyd resin described in the present embodiment is made of the following components in parts by weight:

[0050] 19.34 parts of linseed oil, 0.44 parts of maleic anhydride, 10.55 parts of isophthalic acid, 14.06 parts of trimethylolpropane, 5.71 parts of trimellitic anhydride, 8.79 parts of methyl methacrylate, 0.88 parts of methacrylic acid, benzo peroxide Acyl 0.22 parts, 16.48 parts of propylene glycol methyl ether, 3.96 parts of N-methylmorpholine, 1.98 parts of N,N-dimethylethanolamine and 17.59 parts of water.

[0051] The preparation method step of described waterborne alkyd resin is as follows:

[0052] (1) Put linseed oil, maleic anhydride, isophthalic acid and trimethylolpropane into the reactor and start stirring. After slowly heating to 220-230°C, keep warm until the acid value drops to ≤10mg KOH / g, turn on the cold oil pump, lower the temperature to 150°C; when the temperature drops to 150°C, add trimellitic anhydride at one time, control ...

Embodiment 2

[0056] The water-based alkyd resin described in the present embodiment is made of the following components in parts by weight:

[0057] 20 parts of linseed oil, 0.5 parts of maleic anhydride, 10 parts of isophthalic acid, 15 parts of trimethylolpropane, 5 parts of trimellitic anhydride, 10 parts of methyl methacrylate, 1 part of methacrylic acid, Benzyl peroxide Acyl 0.3 parts, 17 parts of propylene glycol methyl ether, 2.6 parts of N-methylmorpholine, 1.3 parts of N,N-dimethylethanolamine and 20 parts of water.

[0058] Its preparation method refers to the preparation method described in Example 1, and the only difference is that in step (3), benzoyl peroxide is dissolved in 5 parts of propylene glycol methyl ether.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com