Cr<3+>-doped tin-containing mixed spinel near-infrared long-afterglow luminescent material and preparation method thereof

A luminescent material, spinel technology, applied in luminescent materials, chemical instruments and methods, etc., to achieve the effects of low equipment requirements, strong afterglow intensity, and extended selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

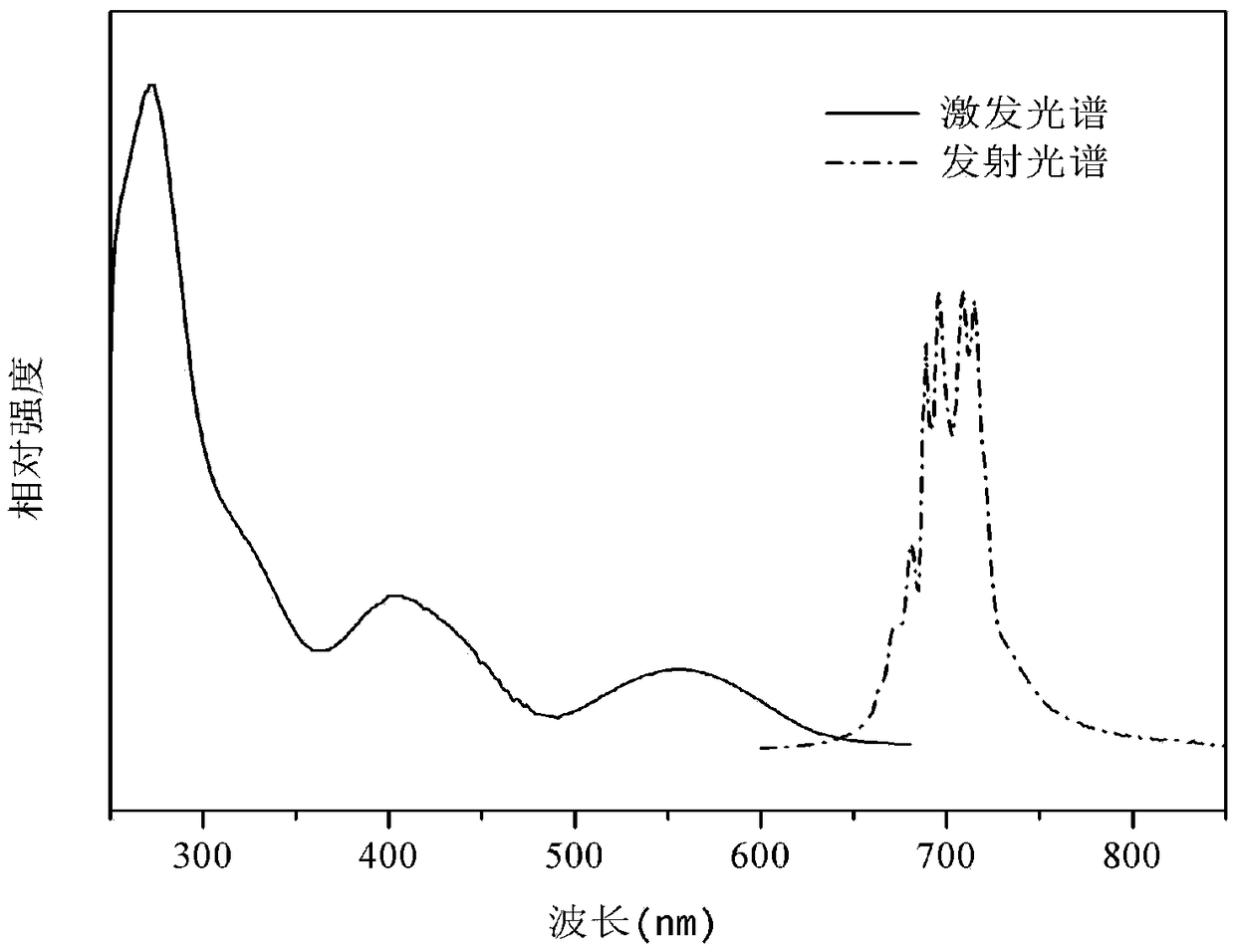

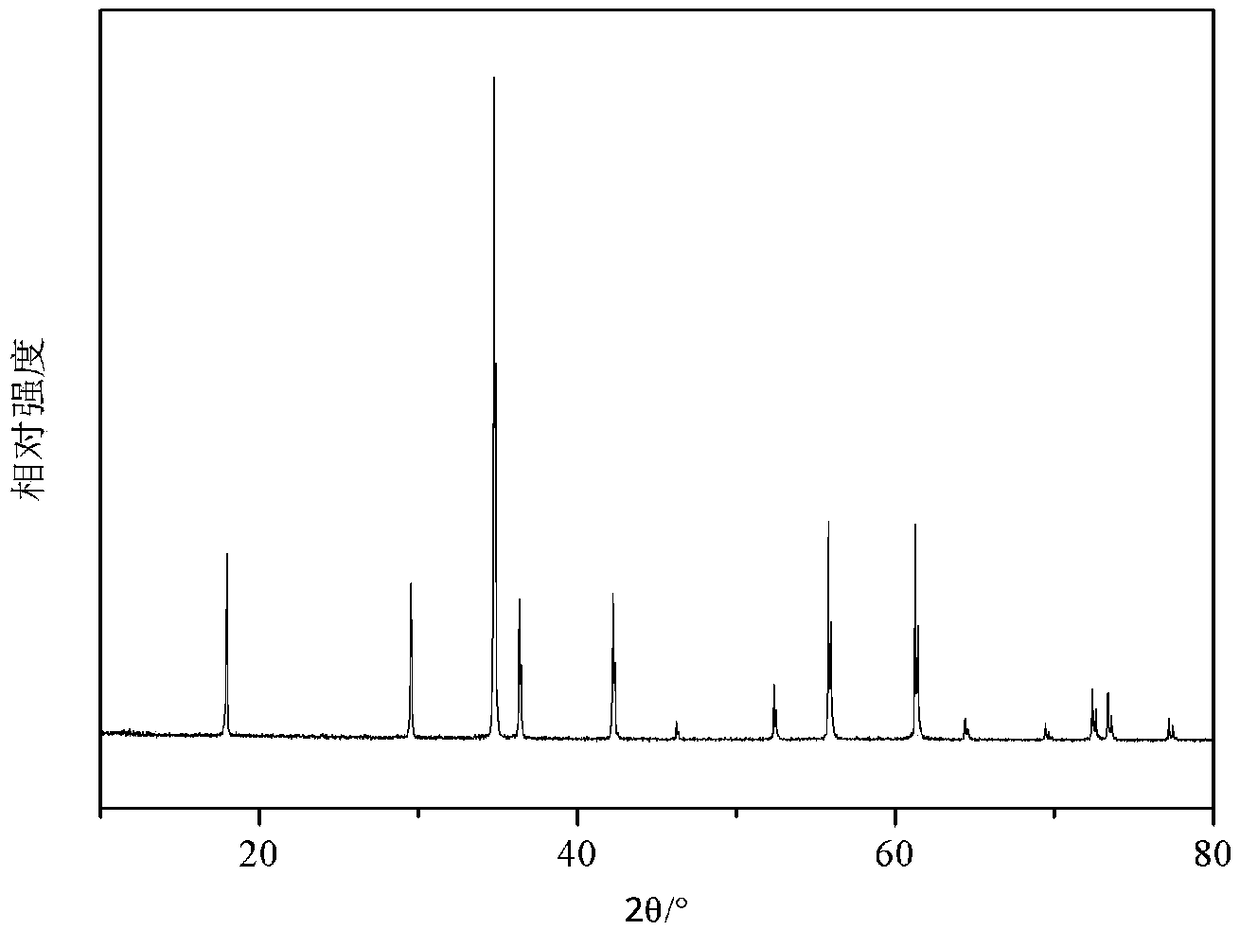

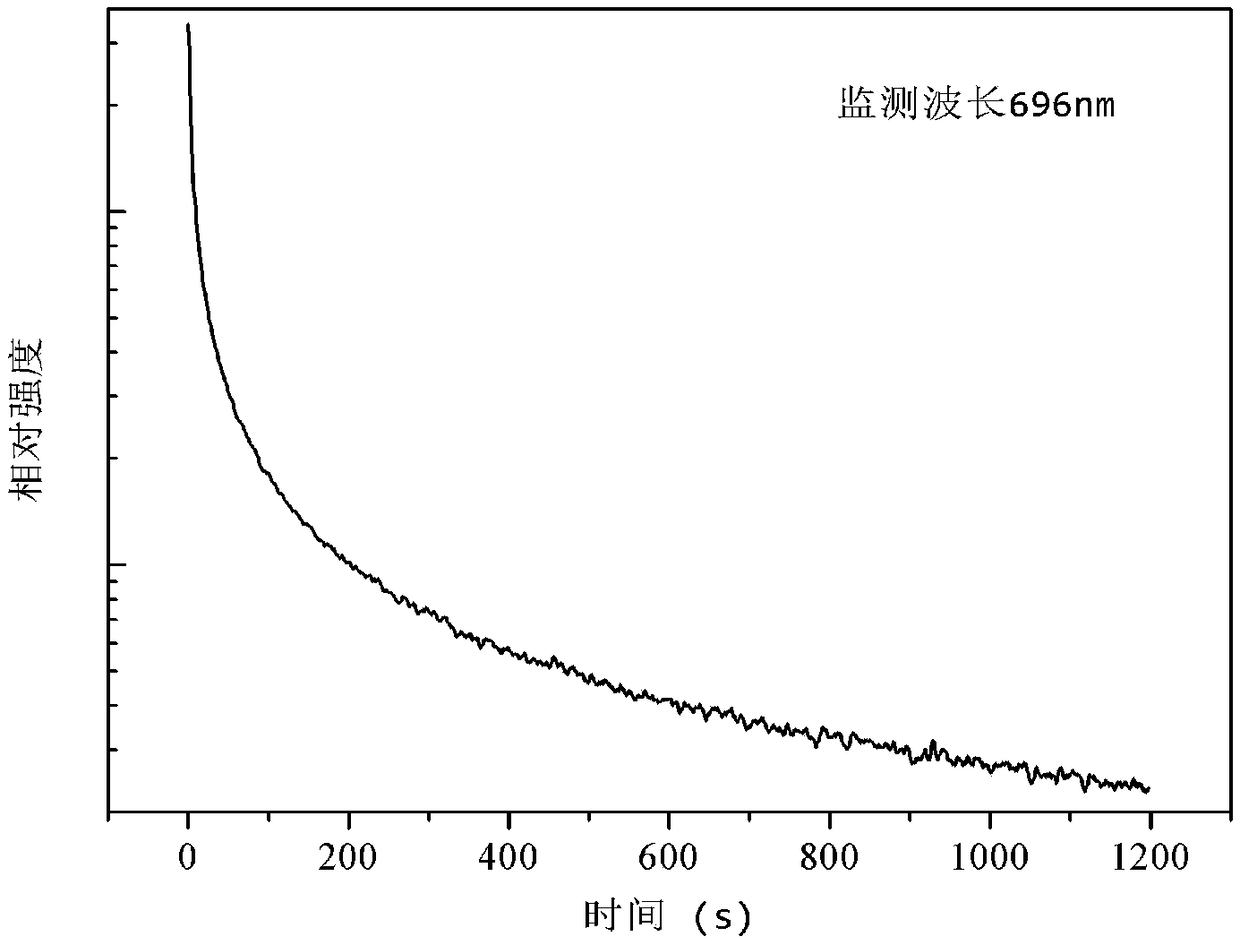

[0023] a Cr 3+ Doped tin-containing mixed spinel structure near-infrared long afterglow material, the material is in powder form, and the molecular formula is as follows: Zn 10 Ga 15.36 SnO 36 :0.08Cr 3+ . The preparation method is as follows: according to the molecular formula ratio, zinc oxide, gallium oxide, tin oxide, and chromium oxide with a purity of more than 99.9% are used as raw materials, and the specific masses are 1.0093g, 1.7851g, 0.1871g, and 0.0075g respectively. Grind the above raw material mixture evenly in an agate mortar, put it into a corundum crucible, raise the temperature to 1350°C at a rate of 10°C / min in an inert nitrogen atmosphere, keep it warm for 8 hours, and then cool it down to room temperature with the furnace . It can be seen from the XRD pattern that the material is a spinel phase, and its excitation and emission spectra are shown in figure 1 As shown in the figure, the solid line part is the excitation spectrum, and the dotted line is ...

Embodiment 2

[0025] a Cr 3+ Doped tin-containing mixed spinel structure near-infrared long afterglow material, the material is in powder form, and the molecular formula is as follows: Zn 12 Ga 19 SnO 44 :0.1Cr 3+ . The preparation method is as follows: according to the molecular formula ratio, zinc oxide, gallium oxide, tin oxide, and chromium oxide with a purity of more than 99.9% are used as raw materials, and the specific masses are 0.9768g, 1.7808g, 0.1509g, and 0.0076g respectively. Grind the above raw material mixture evenly in an agate mortar, put it into a corundum crucible, raise the temperature to 900°C at a heating rate of 10°C / min in an air atmosphere, keep it for 8 hours, and then cool it to room temperature with the furnace. The pre-fired sample was taken out and ground again, and then heated up to 1350°C at a rate of 10°C / min for calcination, kept for 8 hours and then cooled to room temperature with the furnace. The obtained material is a spinel phase, the emission wave...

Embodiment 3

[0027] a Cr 3+ Doped tin-containing mixed spinel structure near-infrared long afterglow material, the material is in powder form, and the molecular formula is as follows: Zn 8 Ga 11.64 SnO 28 :0.06Cr 3+ . The preparation method is as follows: according to the ratio of the molecular formula, zinc oxide, gallium oxide, tin oxide, and chromium oxide with a purity of more than 99.9% are used as raw materials, and the specific masses are 1.0158g, 1.7019g, 0.2353g, and 0.0071g respectively. Grind the above-mentioned raw material mixture evenly in an agate mortar, put it into a corundum crucible, raise the temperature to 1400°C at a rate of 15°C / min in an air atmosphere, keep it for 12 hours, and then cool it to room temperature with the furnace. The obtained material is a spinel phase, the emission wavelength range is between 600-850nm, the emission peak is at about 696nm, and the afterglow can last for more than 24h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com