Preparation method of rice DDGS (Distillers Dried Grains with Soluble) type compound feed for broiler chickens

A technology of DDGS and compound feed is applied in the field of preparation of compound feed for broilers, which can solve the problems of poor chicken meat quality, large use of high-protein raw materials, and high manufacturing cost, and achieve lower feed costs, lower manufacturing feed costs, precision and efficiency. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

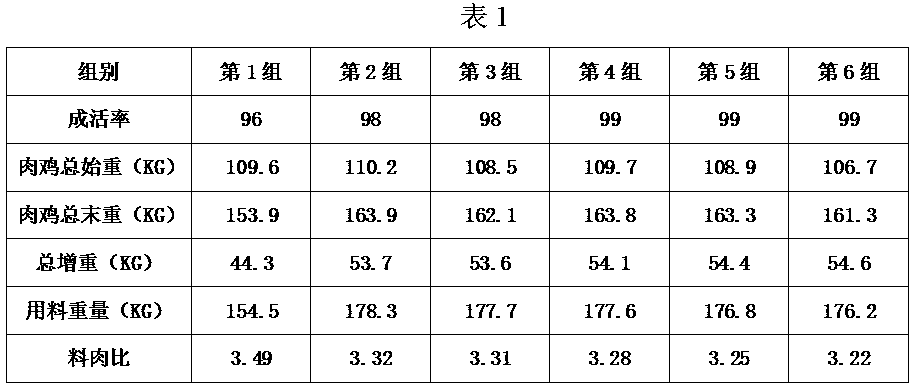

Examples

Embodiment 1

[0021] Raw materials by weight, take corn: 40 parts, wheat secondary flour: 5 parts, rice bran: 6 parts, rice DDGS: 7 parts, feather meal: 1 part, soybean meal: 5 parts, meat and bone meal: 1 part, soybean oil: 0.5 Parts, calcium hydrogen phosphate: 0.1 parts, stone powder: 0.2 parts, sodium chlorophyll: 0.1 parts, lysine: 0.1 parts, methionine: 0.1 parts, choline chloride: 0.03 parts, gypsum powder: 0.1 parts, allicin: 0.05 parts part, compound multidimensional: 0.2 part, compound multimineral: 0.2 part is raw material, and the specific preparation steps are as follows:

[0022] Step 1, raw material cleaning, the raw materials are separately sieved through the cleaning sieve, and the screening rate should reach more than 95%, so as to ensure sufficient screening of raw materials and provide evenly dispersed raw materials for subsequent crushing;

[0023] Step 2: Raw materials are pulverized, and the raw materials are put into a pulverizer with a sieve aperture of 2.0 mm and p...

Embodiment 2

[0030] This example differs from Example 1 only in the proportions by weight of the raw materials, and the rest of the steps are the same. In this embodiment, the raw materials are by weight, corn: 57 parts, wheat secondary flour: 11 parts, rice bran: 12 parts, rice DDGS: 15 parts, feather meal: 6 parts, soybean meal: 15 parts, meat and bone meal: 6 parts, Soybean oil: 2.5 parts, calcium hydrogen phosphate: 0.5 parts, stone powder: 2.5 parts, sodium chlorophyll: 0.6 parts, lysine: 0.8 parts, methionine: 0.5 parts, choline chloride: 0.1 parts, gypsum powder: 0.6 parts, Allicin: 0.4 part, compound multidimensional: 1 part, compound multimineral: 1 part is the raw material.

Embodiment 3

[0032] This embodiment is different from the weight ratio of the raw materials taken in Example 1, and the process parameters in step five are different, and the rest of the steps are the same. In this embodiment, the raw materials are by weight, corn: 48 parts, wheat flour: 7 parts, rice bran: 8 parts, rice DDGS: 10 parts, feather meal: 1 part, soybean meal: 9 parts, meat and bone meal: 1 part, Soybean oil: 0.5 parts, calcium hydrogen phosphate: 0.1 parts, stone powder: 0.55 parts, sodium chlorophyll: 0.2 parts, lysine: 0.2 parts, methionine: 0.1 parts, choline chloride: 0.035 parts, gypsum powder: 0.1 parts, Allicin: 0.052 parts, compound multidimensional: 0.4 parts, compound multimineral: 0.4 parts are raw materials.

[0033] In Step 5 of this embodiment, the steam pressure of the granulator is set to 0.2 MPa, the granulation temperature is set to 70° C., the diameter of the produced granules is 3.0 mm, the length is 1 times the diameter, and the hardness of the granules is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com