Fe<3+> antibiotic fungi residue activated carbon as well as preparation method and application thereof

A technology of antibiotic bacteria residue and activated carbon, which is applied in the field of environmental materials and air pollution, can solve the problems of low treatment efficiency of biofilm degradation, low adsorption efficiency of activated carbon, and easy deactivation of catalysts, and achieve harmless utilization. The effect of high and excellent adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This embodiment is a load Fe 3+ The preparation method of antibiotic slag activated carbon comprises the steps:

[0042] (1) Put the kitasarmycin slag into an oven, dry at 110°C for 2.5 hours, and then grind through a 250-mesh sieve to obtain the under-sieve;

[0043] (2) Immerse the ground bacteria residue in FeCl with a concentration of 80g / L3 In the solution, the shaker was shaken for 24 hours, and filtered with ordinary medium-speed qualitative filter paper;

[0044] (3) Put the filtered fungus residue into an oven, and dry it for 2 hours at 105°C;

[0045] (4) Put the dried slag into a tube furnace, roast at 900°C for 3 hours in a nitrogen atmosphere, cool to room temperature naturally, wash with distilled water, and dry at 100°C to obtain the loaded Fe 3+ Activated charcoal from antibiotic residues.

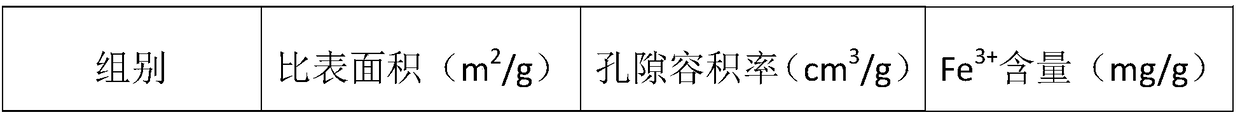

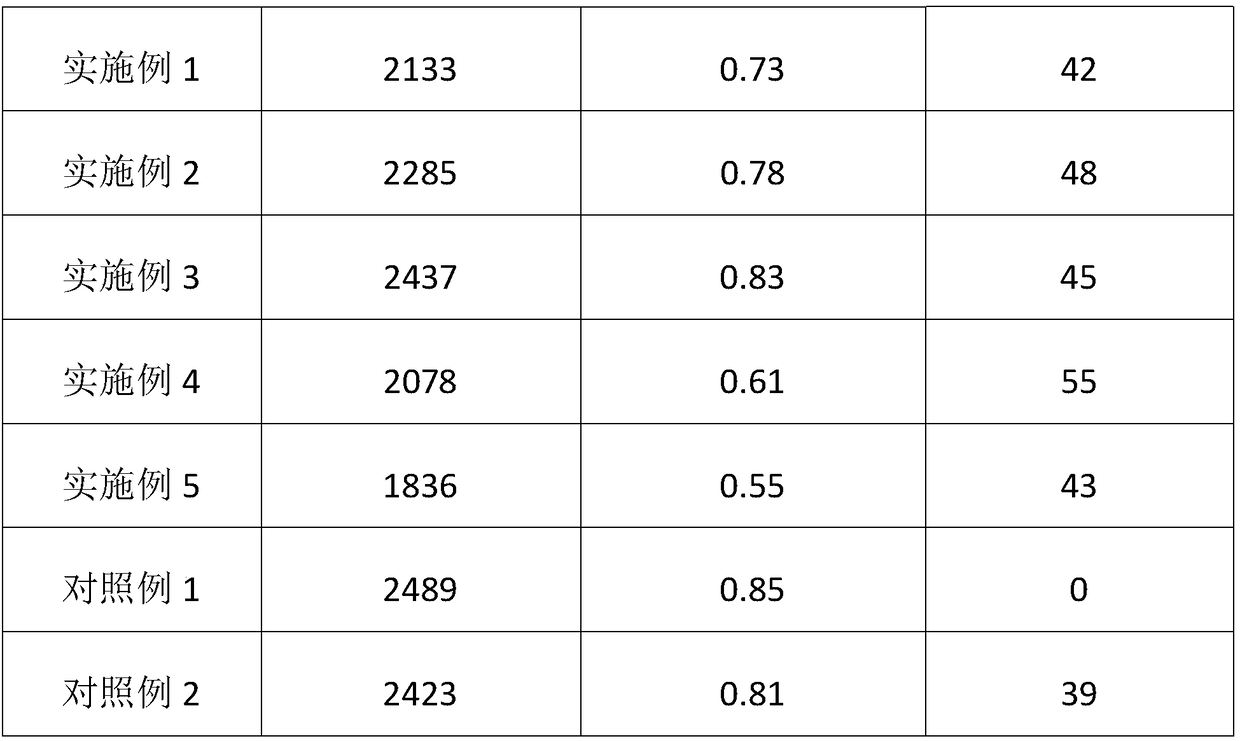

[0046] Measured by a specific surface area analyzer, according to the multi-point BET method, using N 2 The adsorption data calculated above prepared loaded Fe ...

Embodiment 2

[0048] This embodiment is a load Fe 3+ The preparation method of antibiotic slag activated carbon comprises the steps:

[0049] (1) Put the lincomycin residue into an oven, dry at 105°C for 2 hours, and then grind through a 200-mesh sieve to obtain the undersize;

[0050] (2) Immerse the ground bacteria residue in FeCl with a concentration of 120g / L 3 In the solution, the shaker was shaken for 24 hours, and filtered with ordinary medium-speed qualitative filter paper;

[0051] (3) Put the filtered fungus residue into an oven, and dry it for 2 hours at 100°C;

[0052] (4) Put the dried slag into a tube furnace, roast at 700°C for 2 hours in a nitrogen atmosphere, cool to room temperature naturally, wash with distilled water, and dry at 105°C to obtain the loaded Fe 3+ Activated charcoal from antibiotic residues.

[0053] Adopt the detection method of embodiment 1 to the load Fe that above-mentioned preparation obtains 3+ Specific surface area, pore volume ratio and Fe 3+ ...

Embodiment 3

[0055] This embodiment is a load Fe 3+ The preparation method of antibiotic slag activated carbon comprises the steps:

[0056] (1) Put penicillin scum into an oven, dry at 105°C for 2 hours, and then grind through a 200-mesh sieve to obtain undersize;

[0057] (2) Immerse the ground bacteria residue in FeCl with a concentration of 100g / L 3 In the solution, the shaker was shaken for 24 hours, and filtered with ordinary medium-speed qualitative filter paper;

[0058] (3) Put the filtered fungus residue into an oven, and dry it for 2 hours at 105°C;

[0059] (4) Put the dried slag into a tube furnace, roast at 800°C for 2 hours in a nitrogen atmosphere, cool to room temperature naturally, wash with distilled water, and dry at 105°C to obtain the loaded Fe 3+ Activated charcoal from antibiotic residues.

[0060] Adopt the detection method of embodiment 1 to the load Fe that above-mentioned preparation obtains 3+ Specific surface area, pore volume ratio and Fe 3+ The content...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com