A kind of preparation method of copper silicate hollow microsphere

A copper silicate and hollow technology is applied in the field of preparation of copper silicate hollow microspheres, which can solve the problems of complex process and low adsorption capacity, and achieve the effects of uniform material size, wide application and uniform size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

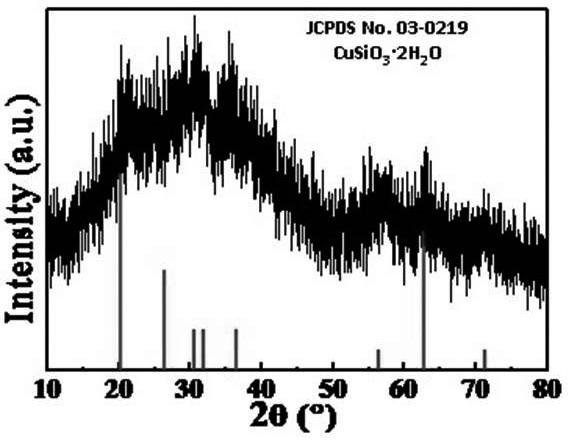

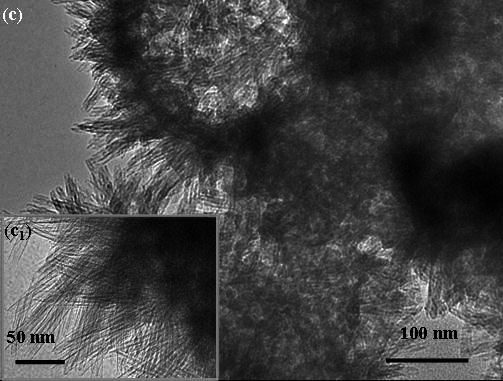

[0042] A preparation method of copper silicate hollow microspheres, comprising the following steps:

[0043] (1) Add 0.75 mmol CuCl 2 and 8 mmol NH 4 The Cl solid was dissolved in 10 mL and 20 mL deionized water respectively, and the obtained NH 4 Cl solution was added dropwise to 10 mL CuCl 2 solution, after stirring evenly, a light green solution A was obtained;

[0044] (2) Add 3 mL NH 3 ·H 2 O, quickly drop into the light green solution A, stir evenly, the solution becomes dark blue solution B;

[0045] (3) Prepare 20 mL of 0.050 mol / L Na 2 SiO 3 Add the aqueous solution dropwise to the dark blue solution B, and stir to obtain a suspension C;

[0046] (4) Put the suspension C in a hydrothermal reaction kettle, raise the temperature to 120 ºC at a heating rate of 8 ºC / min, react at a constant temperature for 12.0 h, and cool to room temperature naturally to obtain a hydrothermal product;

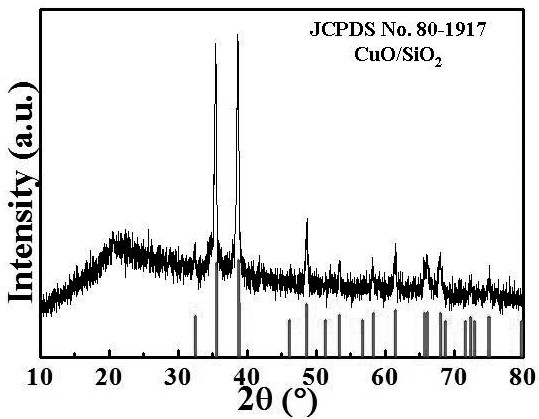

[0047] (5) The hydrothermal product was washed three times with deionized wa...

Embodiment 2

[0054] A preparation method of copper silicate hollow microspheres, comprising the following steps:

[0055] (1) Add 0.75 mmol CuSO 4 and 5 mmol (NH 4 ) 2 SO 4 The solid was dissolved in 10 mL and 20 mL deionized water respectively, and the obtained NH 4 Cl solution was added dropwise to 10 mL CuSO 4 solution, after stirring evenly, a light green solution A was obtained;

[0056] (2) Add 5 mL of ethylenediamine dropwise quickly to the light green solution A, stir evenly, and the solution turns into dark blue solution B;

[0057] (3) Prepare 10 mL of 0.050 mol / L Na 2 SiO 3 Add the aqueous solution dropwise to the dark blue solution B, and stir to obtain a suspension C;

[0058] (4) Put the suspension C in a hydrothermal reaction kettle, raise the temperature to 180 ºC at a heating rate of 5 ºC / min, react at a constant temperature for 6.0 h, and then naturally cool to room temperature to obtain a hydrothermal product;

[0059] (5) The hydrothermal product was washed thr...

Embodiment 3

[0062] A preparation method of copper silicate hollow microspheres, comprising the following steps:

[0063] (1) Add 0.75 mmol Cu(NO 3 ) 2 and 10 mmol NH 4 NO 3 The solid was dissolved in 10 mL and 20 mL deionized water respectively, and the obtained NH 4 Cl solution was added dropwise to 10 mL Cu(NO 3 ) 2 solution, after stirring evenly, a light green solution A was obtained;

[0064] (2) Add 1 mL NaOH dropwise quickly to the light green solution A, and after stirring evenly, the solution turns into dark blue solution B;

[0065] (3) Prepare 20 mL of 0.030 mol / L Na 2 SiO 3 Add the aqueous solution dropwise to the dark blue solution B, and stir to obtain a suspension C;

[0066] (4) Put the suspension C in a hydrothermal reaction kettle, raise the temperature to 90 ºC at a heating rate of 5 ºC / min, react at a constant temperature for 24.0 h, and cool to room temperature naturally to obtain a hydrothermal product;

[0067] (5) The hydrothermal product was washed three...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com