Nitrogen-doped carbon nanosphere as well as preparation method and application thereof

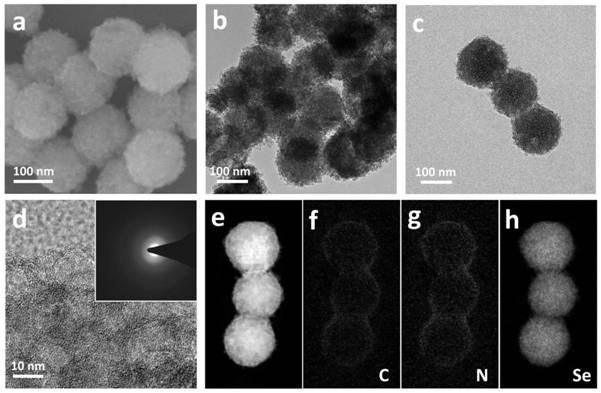

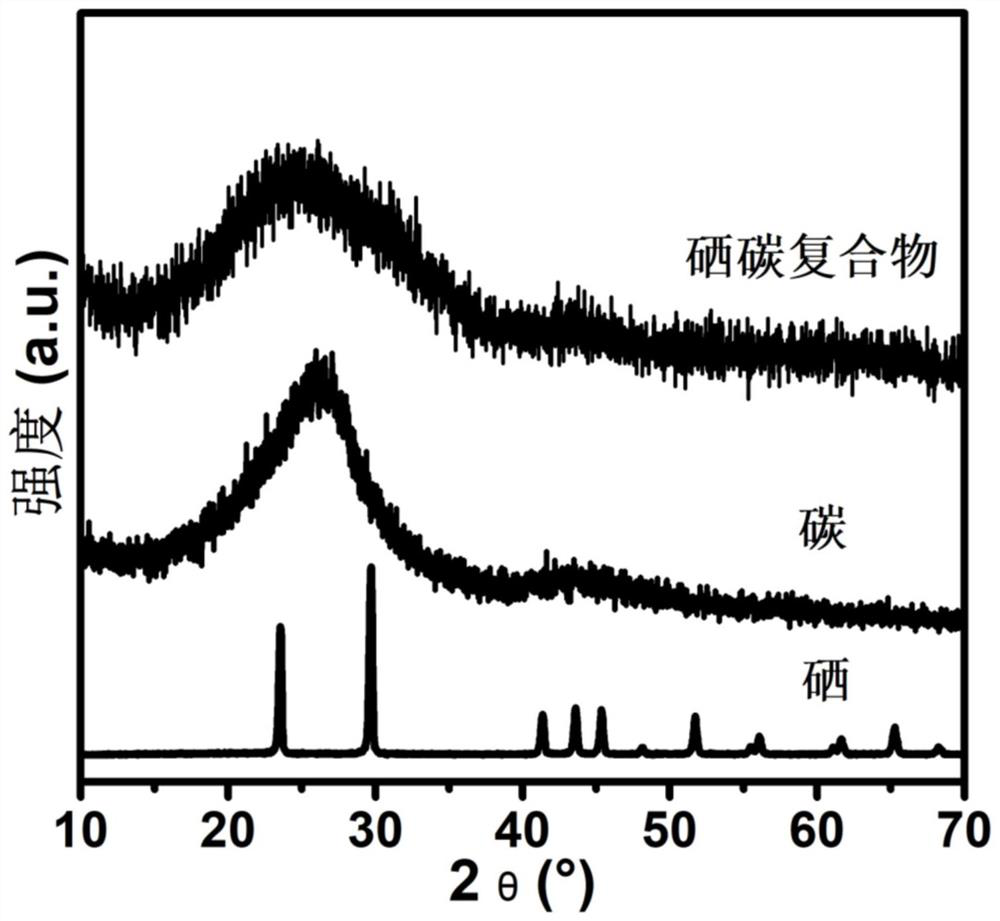

A nitrogen-doped carbon, nanosphere technology, applied in nanocarbon, nanotechnology, nanotechnology and other directions, can solve the problem of not effectively improving the shuttle effect of polyselenide, volume expansion selenium utilization, and the impact of sodium selenium battery electrochemical performance, etc. problems, achieving excellent comprehensive electrochemical performance, easy industrial scale-up, and alleviating volume changes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0101] 1. Preparation of precursor solution;

[0102] At 30°C, add a certain amount of 3ml of ammonia water to a mixed solution of 10ml of deionized water and 75ml of ethanol, then add 6ml of tetraethyl orthosilicate, stir for 5 hours, then centrifuge and dry, and finally continue to dissolve the dried powder by ultrasonic Put it into water to form a colloidal silica solution with a concentration of 20mg / ml.

[0103] 2. Hydrothermal reaction;

[0104] Add 200μl acetic acid dropwise in 20ml water, then add 200mg chitosan powder to dissolve to obtain chitosan solution, then add 50mg hexadecyltrimethylammonium bromide and 10ml silica colloidal solution, stir for 30min evenly and put into high pressure The reactor was subjected to hydrothermal reaction at 180°C for 24h.

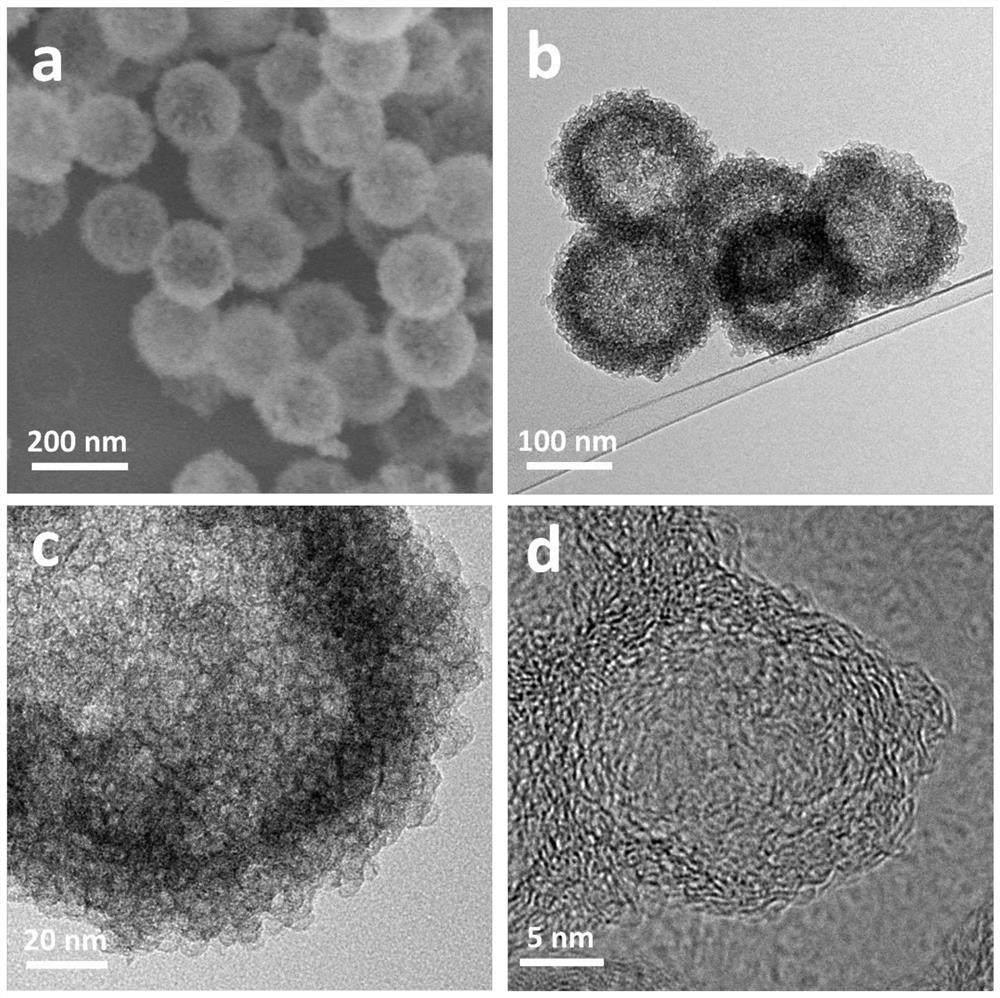

[0105] 3. Calcination process;

[0106] The product after the hydrothermal reaction was centrifuged and dried to obtain carbon nanospheres with a hierarchical multi-cavity hollow structure. After mixing it wit...

Embodiment 2

[0110] 1. Preparation of precursor solution;

[0111]At 30°C, add a certain amount of 3ml of ammonia water to a mixed solution of 10ml of deionized water and 75ml of ethanol, then add 6ml of tetraethyl orthosilicate, stir for 5 hours, then centrifuge and dry, and finally continue to dissolve the dried powder by ultrasonic Add it to water to form a colloidal silica solution with a concentration of 30mg / ml.

[0112] 2. Hydrothermal reaction;

[0113] Add 200μl acetic acid dropwise to 20ml water, then add 100mg chitosan powder to dissolve to obtain chitosan solution, then add 30mg hexadecyltrimethylammonium bromide and 10ml silica colloidal solution, stir for 30min evenly and put into high pressure The reactor was subjected to hydrothermal reaction at 160°C for 48h.

[0114] 3. Calcination process;

[0115] The product after the hydrothermal reaction was centrifuged and dried to obtain carbon nanospheres with a hierarchical multi-cavity hollow structure. After mixing them with...

Embodiment 3

[0119] 1. Preparation of precursor solution;

[0120] At 30°C, add a certain amount of 3ml of ammonia water to a mixed solution of 10ml of deionized water and 75ml of ethanol, then add 6ml of tetraethyl orthosilicate, stir for 5 hours, then centrifuge and dry, and finally continue to dissolve the dried powder by ultrasonic Add it to water to form a colloidal silica solution with a concentration of 10mg / ml.

[0121] 2. Hydrothermal reaction;

[0122] Add 200μl acetic acid dropwise to 20ml water, then add 100mg chitosan powder to dissolve to obtain chitosan solution, then add 20mg hexadecyltrimethylammonium bromide and 10ml silica colloidal solution, stir for 30min evenly and put into high pressure The reactor was subjected to hydrothermal reaction at 200°C for 36h.

[0123] 3. Calcination process;

[0124] The product after the hydrothermal reaction was centrifuged and dried to obtain carbon nanospheres with a hierarchical multi-cavity hollow structure. After mixing them wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com