Inorganic penetration waterproof agent

A waterproofing, inorganic technology, applied in the field of building materials, can solve the problems of poor waterproof performance and poor self-repairing ability, and achieve the effect of increasing the load, good monodispersity, and improving self-compacting performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

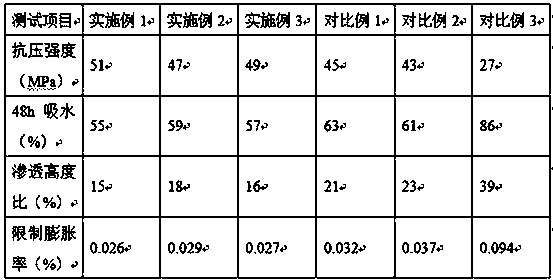

Examples

preparation example Construction

[0025] The preparation method of the slow-osmosis self-healing active substance is as follows:

[0026] S1. Take the nano-ferric oxide powder and add ethanol with a mass fraction of 90% according to the mass ratio of 1~4:10~15, and then add methacrylic acid-3-(trimethacrylic acid) with a mass ratio of 10-20% of the nano-ferric oxide powder. Oxysilyl) propyl ester, ultrasonically dispersed for 20~30min to obtain an ultrasonic dispersion, heated to 65~70°C, added ammonia water with 5~10% of the mass of the ultrasonic dispersion, stirred and mixed for 12~15h, attracted by a magnet, and the attractant Wash with ultrapure water and absolute ethanol, and dry to obtain a dried product;

[0027] S2. Take the dry matter and add ultrapure water according to the mass ratio of 2~5:40~70, pass through nitrogen protection, add glycidyl methacrylate 2~5 times the amount of dry matter and 30~50% of the amount of dry matter Vinylbenzene, stir and mix at 70~75°C for 20~30min to obtain a stirre...

Embodiment 1

[0038] The preparation method of the slow-osmosis self-healing active substance is as follows:

[0039] S1. Take the nano-ferric oxide powder and add ethanol with a mass fraction of 90% at a mass ratio of 1:10, and then add methacrylic acid-3-(trimethoxysilyl)acrylic acid with a mass ratio of 10% of the nano-ferric oxide powder. Esters were ultrasonically dispersed for 20 minutes to obtain an ultrasonic dispersion, heated to 65°C, added ammonia water with 5% mass of the ultrasonic dispersion, stirred and mixed for 12 hours, attracted by a magnet, washed with ultrapure water and absolute ethanol, and dried to obtain a dry thing;

[0040] S2. Take the dry matter and add ultrapure water according to the mass ratio of 2:40, pass through nitrogen protection, add glycidyl methacrylate twice the amount of dry matter and divinylbenzene with 30% of the dry matter, and stir at 70°C Mix for 20 minutes to obtain a stirred mixture, take the stirred mixture and add potassium persulfate at ...

Embodiment 2

[0051] The preparation method of the slow-osmosis self-healing active substance is as follows:

[0052] S1. Take the nano-ferric oxide powder and add ethanol with a mass fraction of 90% at a mass ratio of 3:12, and then add methacrylic acid-3-(trimethoxysilyl)acrylic acid with a mass ratio of 15% of the nano-ferric oxide powder. Ester, ultrasonically dispersed for 25 minutes to obtain an ultrasonic dispersion, heated to 68°C, added ammonia water with 8% mass of the ultrasonic dispersion, stirred and mixed for 14 hours, attracted by a magnet, washed with ultrapure water and absolute ethanol, and dried to obtain a dry thing;

[0053] S2. Take the dry matter and add ultrapure water according to the mass ratio of 3:65, pass through nitrogen protection, add glycidyl methacrylate with 4 times the amount of dry matter and divinylbenzene with 40% of the dry matter, and stir at 73°C Mix for 25 minutes to obtain a stirred mixture. Take the stirred mixture and add potassium persulfate a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com