Method using plasma to induce synthesis of chitosan-based flocculant

A plasma and chitosan technology, applied in the direction of flocculation/precipitation water/sewage treatment, etc., can solve the problems of destroying the molecular structure of polymers, reagent pollution, high energy consumption, and achieve enhanced water solubility, strong hydration ability, and performance. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

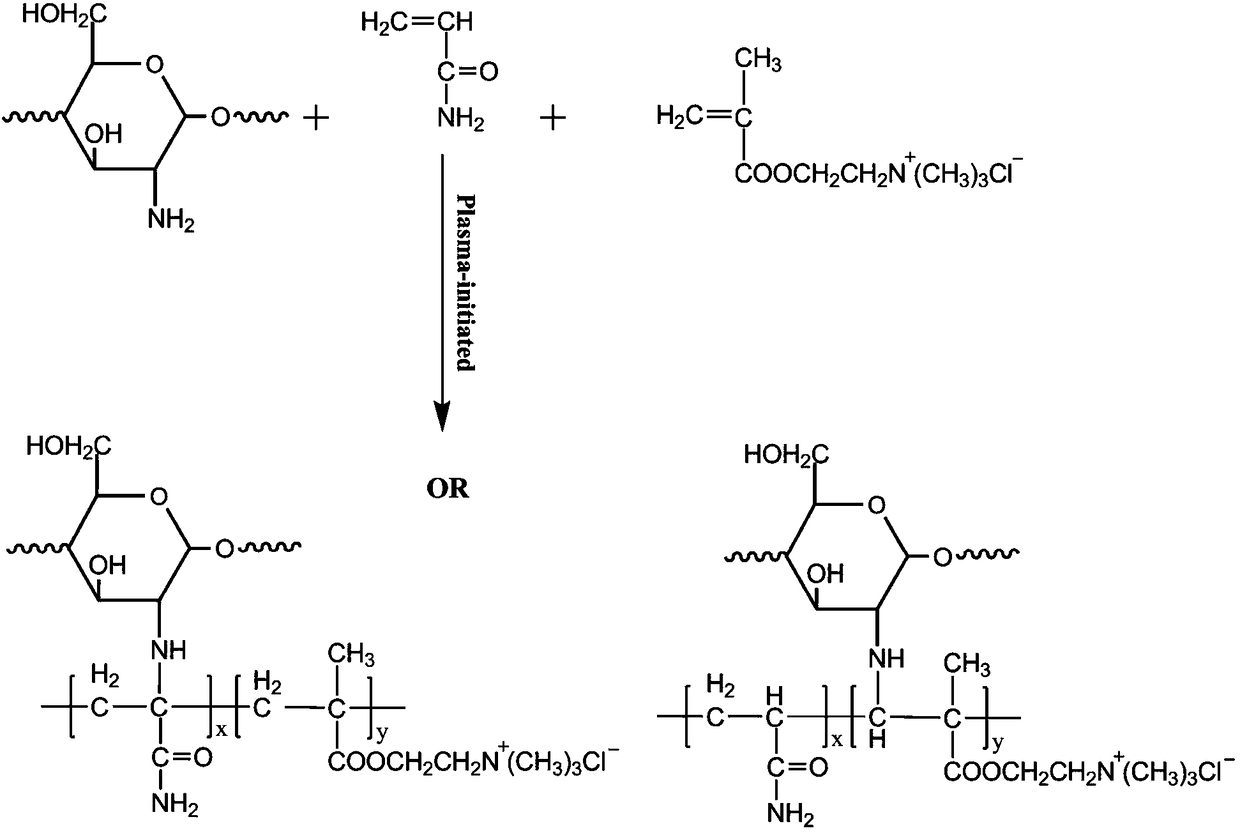

Method used

Image

Examples

Embodiment 1

[0028] The preparation method of present embodiment chitosan-based flocculant comprises the steps:

[0029] 1) Add 2g of chitosan powder into 25mL of dilute acetic acid solution with a mass fraction of 1.0%, and stir slowly until dissolved to obtain an aqueous solution of chitosan;

[0030] 2) Weigh 8.2g of acrylamide and 3.8g of methacryloyloxyethyltrimethylammonium chloride in turn, put them into the reactor, add 28g of deionized water, stir evenly, and prepare a total concentration of 30%. Monomer solution;

[0031] 3) Add chitosan aqueous solution to the above-mentioned total monomer solution, stir evenly, then add sodium hydroxide solution or hydrogen chloride solution, and adjust the pH value of the above-mentioned mixed solution to 4.5;

[0032] 4) Place the above-mentioned mixed solution in a glow discharge electrolysis device, and use plasma to initiate a polymerization reaction. First fill the reaction device with high-purity nitrogen to remove oxygen for 15 minute...

Embodiment 2

[0036] The preparation method of present embodiment chitosan-based flocculant comprises the steps:

[0037] 1) Add 2g of chitosan powder into 25mL of dilute acetic acid solution with a mass fraction of 1.0%, and stir slowly until dissolved to obtain an aqueous solution of chitosan;

[0038] 2) Weigh 9.5g of acrylamide and 4.5g of methacryloyloxyethyltrimethylammonium chloride in turn, put them into the reactor, add 26g of deionized water, stir evenly, and prepare a total concentration of 35%. Monomer solution;

[0039] 3) Add chitosan aqueous solution to the above-mentioned total monomer solution, stir evenly, then add sodium hydroxide solution or hydrogen chloride solution, and adjust the pH value of the above-mentioned mixed solution to 5;

[0040]4) Place the above-mentioned mixed solution in a glow discharge electrolysis device, and use plasma to initiate a polymerization reaction. First fill the reaction device with high-purity nitrogen to remove oxygen for 20 minutes, ...

Embodiment 3

[0044] The preparation method of present embodiment chitosan-based flocculant comprises the steps:

[0045] 1) Add 1.5g of chitosan powder into 20mL of dilute acetic acid solution with a mass fraction of 1.0%, and stir slowly until dissolved to obtain an aqueous solution of chitosan;

[0046] 2) Weigh 6.8g of acrylamide and 2.7g of methacryloyloxyethyltrimethylammonium chloride in turn, put them into the reactor, add 36g of deionized water, stir evenly, and prepare a total concentration of 20.9%. Monomer solution;

[0047] 3) Add chitosan aqueous solution to the above-mentioned total monomer solution, stir evenly, then add sodium hydroxide solution or hydrogen chloride solution, and adjust the pH value of the above-mentioned mixed solution to 5;

[0048] 4) Place the above-mentioned mixed solution in a glow discharge electrolysis device, and use plasma to initiate a polymerization reaction. First fill the reaction device with high-purity nitrogen to remove oxygen for 25 minu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com